Page 13

Table 6

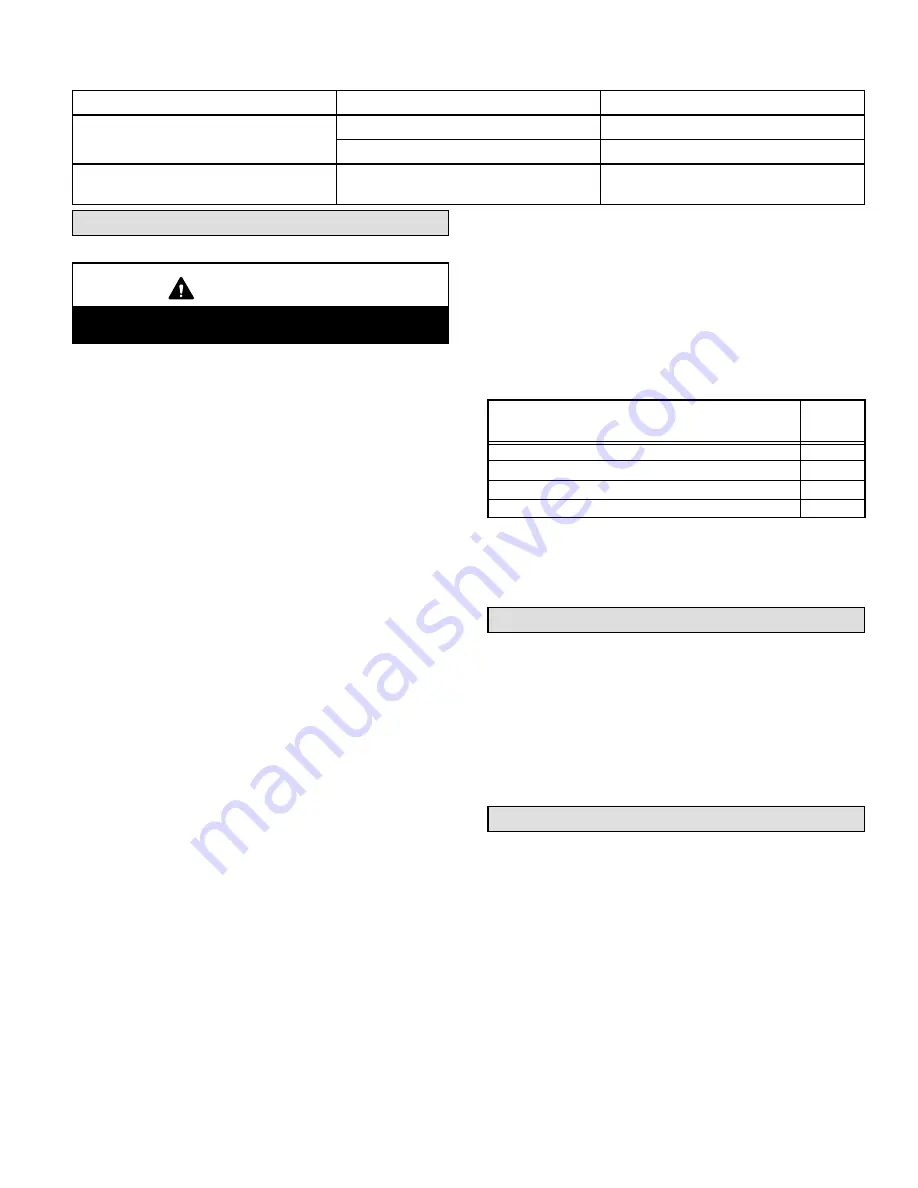

Fuel Pump Usage

Pump

Piping Application

Maximum Lift (vacuum)

Single-Stage Pump

One-Pipe System

8 ft. (6” Hg vacuum)

Two-Pipe System

10 ft. (12” Hg vacuum)

Two-Stage Pump

Two-Pipe System

10 ft. or greater

(12” to 17” Hg vacuum)

Oil Supply Line & Filter Connections

One-Pipe Systems

CAUTION

Do not install the bypass plug into the pump on one-

pipe systems.

The burner is shipped with fuel pump set for one-pipe op

eration. For one-pipe systems, the oil supply pipe is con

nected to the inlet tap on the pump. A one-pipe system

should only be used where there is gravity oil flow to the

pump and the pipe is not run at any point above the oil level

in the tank.

1 - Connect the inlet pipe to the pump inlet. Start the

burner.

2 - Set the primary burner control for continuous opera

tion during purging.

3 - Turn the bleed valve one turn counterclockwise to

open.

4 - Bleed the unit until all air bubbles disappear.

NOTE - Hurried bleeding will prevent the unit from op

erating properly.

5 - Tighten the bleed valve securely.

Two-Pipe Systems

If the installation requires a two-pipe operation, install the

bypass plug included in the bag which is attached to the

pump. To convert the pump, install the bypass plug ac

cording to the provided pump instructions. Notice in the

two‐pipe system the return pipe must terminate in the tank

3” (76 mm) to 4” (102 mm) above the supply inlet. Ensure

the return pipe terminates at the correct measurement or

air may escape into the system. This could result in loss of

prime.

NOTE- If using an outside tank in cold climates a number

one fuel or an oil treatment is strongly recommended.

1 - Remove 1/4” plug from return port.

2 - Insert bypass plug and tighten it. See figure 13.

3 - Attach the return and inlet pipes. Start the burner. Air

bleeding is automatic.

NOTE - If a faster bleed is necessary, open the bleed

valve.

4 - The return pipe must terminate 3” to 4” above the sup

ply pipe inlet. See figure 13.

NOTE - If the return pipe does not terminate where it

should, air may enter the system, and prime may be

lost.

An oil filter is required for all models.

Install a field sup

plied oil filter inside the building between the tank shut‐off

valve and the burner. Locate filter close to burner for easy

maintenance. Table 7 lists the filters for the ELO183DH

furnace.

Table 7

Oil Filters

Cat.

Number

10 micron filter (no mounting bracket)

81P89

10 micron filter (mounting bracket)

53P92

10 micron replacement cartridge for filter, 45 gph

53P93

Filter restriction indicator gauge

53P90

Consult burner manufacturer's instructions packaged with

unit for further details concerning oil supply pipe connec

tions.

Leak Check

After oil piping is completed, carefully check all piping con

nections (factory and field) for oil leaks.

Oil Line Heater (Optional)

A heater for the oil line is available for applications that are

located in cold climates. The heater warms the oil pipe to

assist the initial start-up. An oil line heater is available from

Beckett using part number 51621 (Beckett Start Helper).

Electrical Wiring

All wiring must conform to the National Electric Code

(NEC), or Canadian Electric Code (CEC) and any local

codes.

1 - Refer to the appliance rating plate for proper fuse size.

2 - Install the room thermostat and make wire connec

tions to the control. Avoid installing thermostat on an

outside wall or where it can be affected by radiant heat.

Set the adjustable heat anticipator on thermostat ac

cording to the wiring diagram sticker provided on unit.

3 - Install a separate fused disconnect switch near unit so

power can be shut off for servicing.