Page 4

Requirements

WARNING

Product contains fiberglass wool.

Disturbing the insulation in this product during

installation, maintenance, or repair will expose you

to fiberglass wool dust. Breathing this may cause

lung cancer. (Fiberglass wool is known to the State

of California to cause cancer.)

Fiberglass wool may also cause respiratory, skin,

and eye irritation.

To reduce exposure to this substance or for further

information, consult material safety data sheets

available from address shown below, or contact your

supervisor.

Lennox Industries Inc.

P.O. Box 799900

Dallas, TX 75379−9900

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, person-

al injury or loss of life. Installation and service must

be performed by a qualified installer or service

agency.

Installation of Lennox oil−fired furnaces must conform with

the National Fire Protection Association Standard for the

Installation of Oil Burning Equipment, NFPA No. 31, the

National Electrical Code, ANSI/NFPA No.70 (in the

U.S.A.), CSA Standard CAN/CSA−B139 (in Canada),

Installation Code for Oil Burning Equipment, the Canadian

Electrical Code Part1, CSA 22.1 (Canada), the recommen-

dations of the National Environmental Systems Contrac-

tors Association and any state or provincial laws or local or-

dinances. Authorities having jurisdiction should be

consulted before installation. Such applicable regulations

or requirements take precedence over general instructions

in this manual.

Chimneys and chimney connectors must be of the type and

construction outlined in section 160 of NFPA No. 31.

Air for combustion and ventilation must conform to stan-

dards outlined in section 140 of NFPA No. 31 or, in Canada,

CSA Standard B139. When installing ELO183UF units in

confined spaces such as utility rooms, two combustion air

openings are required. Dimensions of combustion air

openings are shown in table 1. One opening shall be below

burner level and the other opening shall be no more than

6"(152 mm) from the room’s ceiling.

The combustion air opening should provide a minimum

free area one-half square inch per 1,000 Btu per hour input.

This combustion air should be brought into the area con-

taining the furnace below the level of the furnace burner.

IMPORTANT

An opening to the outside for combustion air is

strongly recommended, especially in new homes.

Refer to table 2 or the unit rating plate for specific

combustion air opening dimensions.

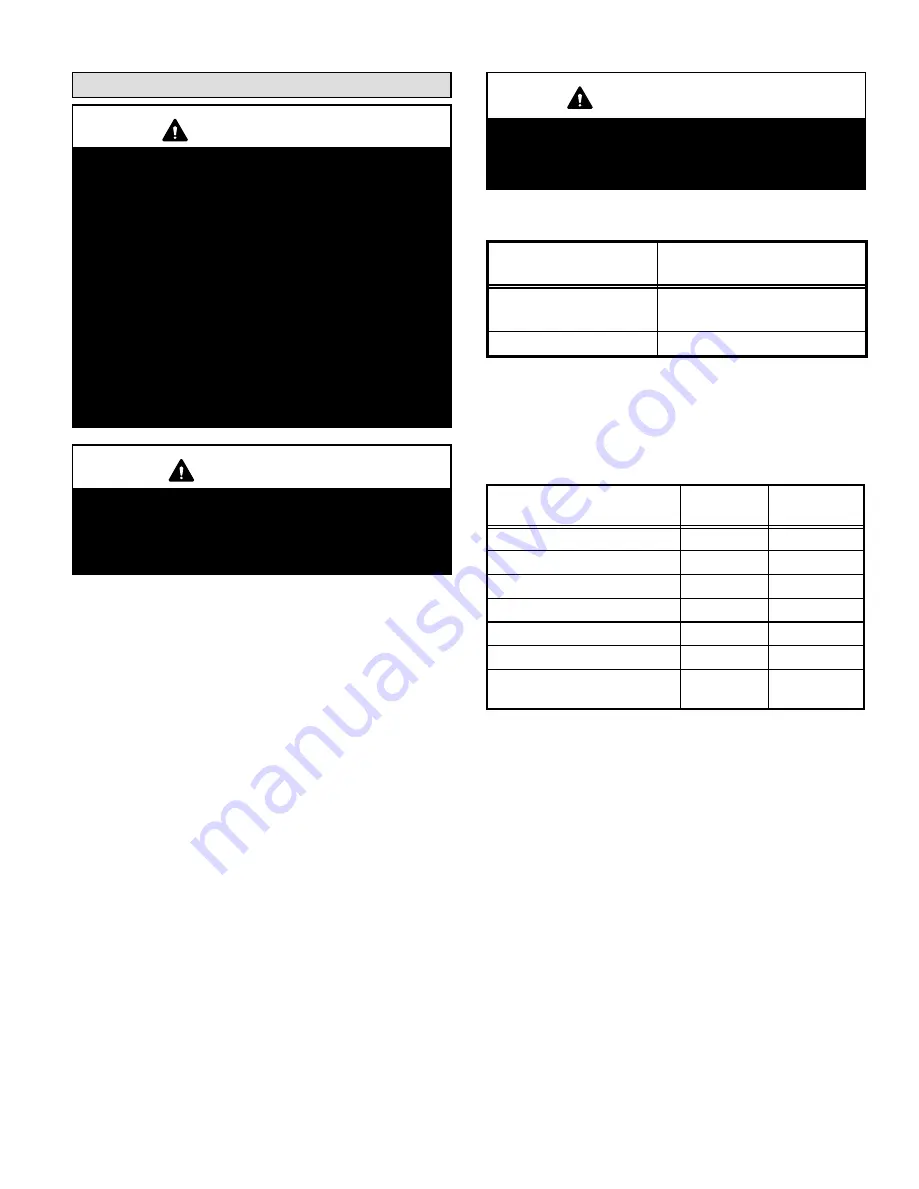

Table 1

Combustion Air Opening Dimensions

Model No.

Combustion Air Opening

Dimensions (2 required)

ELO183UF−68/86/

101/114

11" X

10" X 20"

(254 mm X 508 mm)

ELO183UF−135/150

22" (279 mm X 559 mm)

This unit is approved for use on combustible flooring and

for clearances to combustible material as listed on unit rat-

ing plate and in table 2. Unit service and accessibility clear-

ances take precedence over fire protection clearances.

Table 2

Installation Clearances inches (mm)

Clearances

68/86/101/

114

135/150

top of cabinet

2 (51)

2 (51)

cabinet sides

0 (0)

0 (0)

cabinet rear

0 (0)

0 (0)

cabinet front

4 (120)

4 (120)

top of plenum and duct

2 (51)

2 (51)

plenum sides

3 (76)

3 (76)

flue pipe measured

horizontally and vertically*

6 (152)

6 (152)

NOTE − Service access clearance (24 in. front) must be maintained.

*Minimum clearance shown for flue pipe may be reduced by using special

protection as provided by local building codes and the National Fire

Protection Association Standards.

NOTE − When service clearances are greater than fire

protection clearances, service clearances take prece-

dence.

Unit must be adjusted to obtain a temperature rise in the

range listed in table 7 in the Start-Up section of this manual.

When installed, furnace must be electrically grounded in

accordance with local codes or, in the absence of local

codes, with the current National Electric Code, ANSI/NFPA

No. 70, or Canadian Electric Code (CEC) if an external

electrical source is utilized.

Field wiring connection with unit must meet or exceed

specifications of type T wire and withstand a 63

_

F (17

_

C)

temperature rise.

When furnace is used in conjunction with cooling units, it shall

be installed in parallel with, or on the upstream side of, cooling

units to avoid condensation in the heating element. With a

parallel flow arrangement, a damper (or other means to con-