Page 5

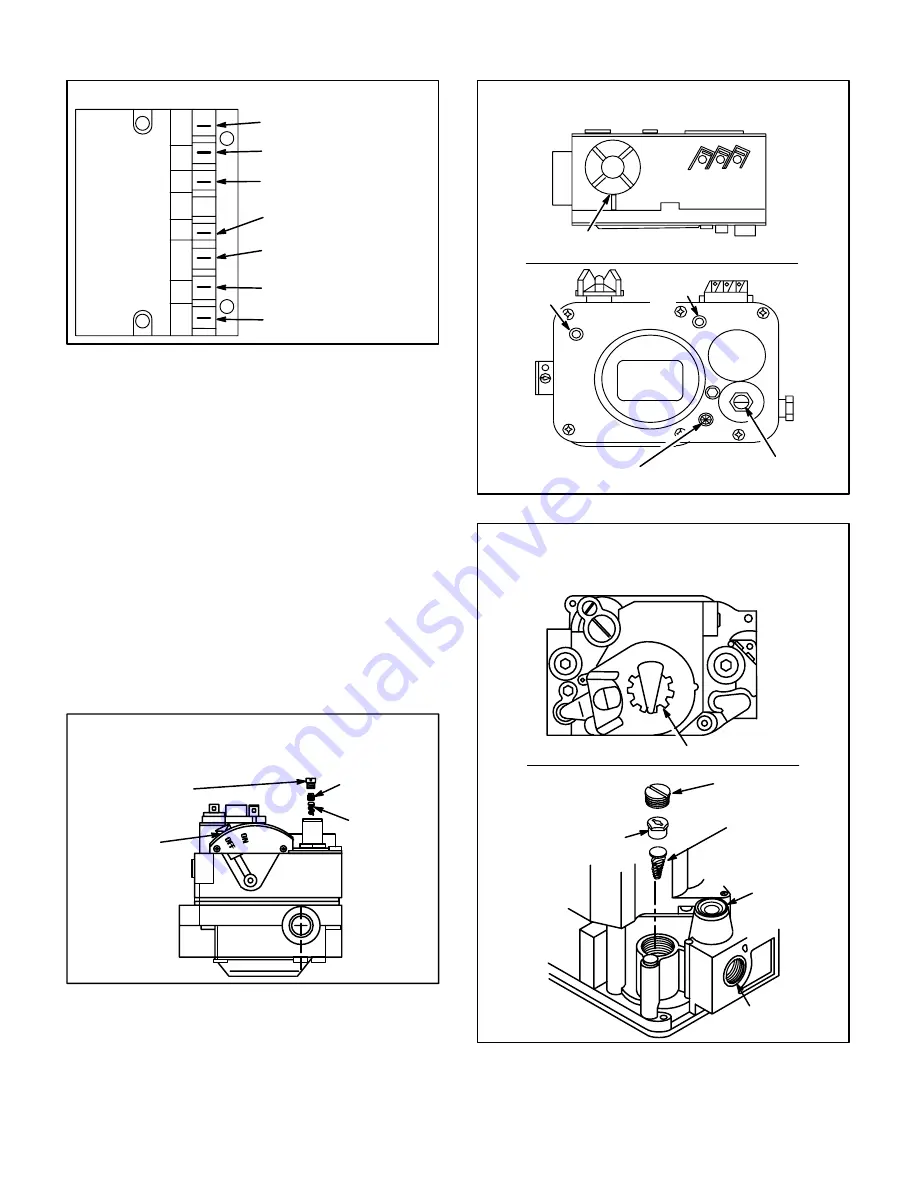

ROBERTSHAW IGNITION CONTROL

FIGURE 6

MAIN AND PILOT

VALVE COMMON

24VAC OUTPUT

TO MAIN VALVE

24VAC OUTPUT TO PILOT

24VAC INPUT FROM BCC2-2

MICROAMP SIGNAL

FROM FLAME

SENSOR

COMMON

HIGH VOLTAGE

TO SPARK IGNITOR

TR

IGN

SENSE

TH

MV

MV/PV

PV

G-Gas Valve

The G17 uses a gas valve manufactured by Robertshaw or

Honeywell. The valve is internally redundant to assure safety

shut-off. If the gas valve must be replaced, the same type

valve must be used.

24VAC terminals and gas control knob are located on top of

the valve. All terminals on the gas valve are connected to

wires from the electronic ignition control. 24V applied to termiĆ

nal P" energizes the pilot valve. An orange sensing wire from

terminal V"(marked VALVE SENSE) of the BCC2-2 control

rides piggy back" on the P" terminal connection. 24V applied

to terminal M" energizes the main valve. Terminal C" proĆ

vides 24V common.

Inlet and outlet pressure taps are located on the valve. A

pilot adjusting screw and regulator adjustment screw (figĆ

ures 7 and 9) are located on the valve. Refer to figure 8 for

exact location of valve features.

FIGURE 7

(Robertshaw 7200 gas valve shown)

GAS VALVE

SELECTOR

ARM

IN OFF

POSITION

REGULATOR

COVER SCREW

ADJUSTING

SCREW

SPRING

TYPICAL ACCESS TO REGULATOR

FOR ADJUSTMENT AND L.P. CHANGEOVER

An LPG changeover kit is available from Lennox. The kit inĆ

cludes main and pilot burner orifices, burner air adjustment

shutters and a regulating conversion kit.

ON

OFF

FIGURE 8

(Robertshaw 7100 gas valve shown)

GAS VALVE KNOB SHOWN IN

OFF POSITION

P C M

PRESSURE REGULATOR

ADJUSTMENT SCREW

TOP VIEW

FRONT

VIEW

PILOT

ADJUSTMENT SCREW

INLET

PRESSURE

TAP

VALVE

INLET

VALVE

OUTLET

OUTLET

PRESSURE

TAP

TYPICAL GAS VALVE COMPONENTS

FIGURE 9

TYPICAL ACCESS TO REGULATOR

FOR ADJUSTMENT AND L.P. CHANGEOVER

ON

OFF

(Honeywell VR8204 series gas valve shown)

GAS VALVE SHOWN IN OFF POSITION

INLET

PRESSURE

TAP

CAP SCREW

(Black)

ADJUSTING SCREW

(White)

SPRING

Tapered End

Down

(Red)

GAS INLET

PRESSURE

REGULATOR