Page 16

11-Set thermostat to desired setting.

NOTE-When unit is initially started, steps 1 through 11

may need to be repeated to purge air from pilot line.

12-If the appliance still will not operate, follow the instrucĆ

tions To Turn Off Gas To Unit" and call your service

technician or gas supplier.

To Turn Off Gas To Unit

1- Set thermostat to lowest setting.

2- Turn off all electrical power to unit if service is to be perĆ

formed.

3- Remove lower access panel.

4- On Honeywell VR8204 gas valves, turn knob on gas

valve clockwise

to

OFF

. Units with Robertshaw 7200

gas valve, depress lever and move to

OFF

position. Do

not force.

5- Replace lower access panel.

HIGH ALTITUDE INFORMATION

G20R series units are certified for installations from 0 to

4000 feet (0 to 1219m) above sea level without modificaĆ

tion. For installations from 4000 feet to 7500 feet (1219m

to 2286m) above sea level, a high altitude kit (44H56)

must be installed. The kit contains special flue baffles

used to replace factory-installed baffles. No derate is reĆ

quired.

GAS PRESSURE ADJUSTMENT

Gas Flow

To check for proper gas flow to combustion chamber, deĆ

termine Btu input from appliance rating plate. Divide this

input rating by the Btu per cubic foot of available gas. ReĆ

sult is the required number of cubic ft. per hour. DeterĆ

mine the flow of gas through gas meter for two minutes

and multiply by 30 to get the hourly flow of gas to burner.

Gas Pressure

1- Check gas line pressure with unit firing at maximum

rate.

A minimum of 4.5" w.c. (1.12kPa) for natural

gas or 10.5" w.c. (2.61kPa) for LP/propane gas

should be maintained.

2-

After line pressure has been checked and adjusted,

check manifold pressure. Correct manifold presĆ

sure for LP/propane gas is 9.5" w.c. (2.36kPa) No adĆ

justment is needed in high altitude applications.

A natural gas to LP/propane gas changeover kit is

required to convert unit. Refer to the installation

instructions supplied with changeover kit for conĆ

version procedure.

Correct manifold pressure for natural gas is 3.5"

w.c. (.87kPa). No adjustment is needed in high altiĆ

tude applications.

See figures 22 and 21 for gas

pressure adjustment screw location.

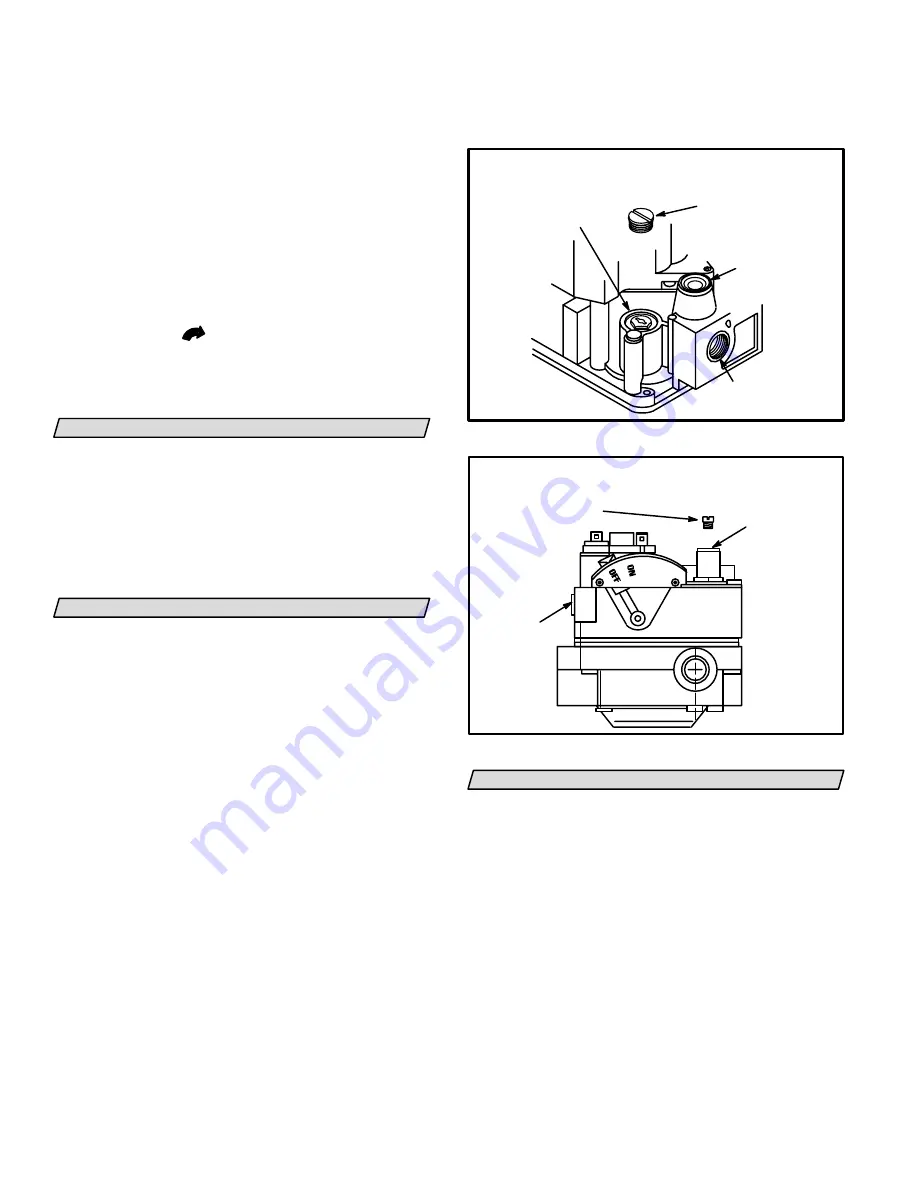

INLET

PRESSURE

TAP

HONEYWELL GAS VALVE

REGULATOR ADJUSTMENT SCREW LOCATION

CAP SCREW

(Black)

ADJUSTING SCREW

(White)

GAS INLET

PRESSURE REGULATOR

FIGURE 21

ROBERTSHAW 7200 GAS VALVE

REGULATOR ADJUSTMENT SCREW LOCATION

FIGURE 22

REGULATOR

COVER SCREW

ADJUSTING

SCREW

INLET

PRESSURE

TAP

OTHER UNIT ADJUSTMENTS

Limit Control

Limit Control-Factory set at 90 seconds: No adjustment

necessary. If nuisance tripping of limit control occurs, fan

may need to run longer. See Fan Control section below.

Fan Control

The fan on time of 45 seconds is not adjustable. Fan off

time (time that the blower operates after the heat deĆ

mand has been satisfied) can be adjusted by moving

the jumper on the BCC blower control center. The unit

is shipped with a factory fan off setting of 90 seconds.

Fan off time will affect comfort and is adjustable to satĆ

isfy individual applications. See figure 23.