Page 6

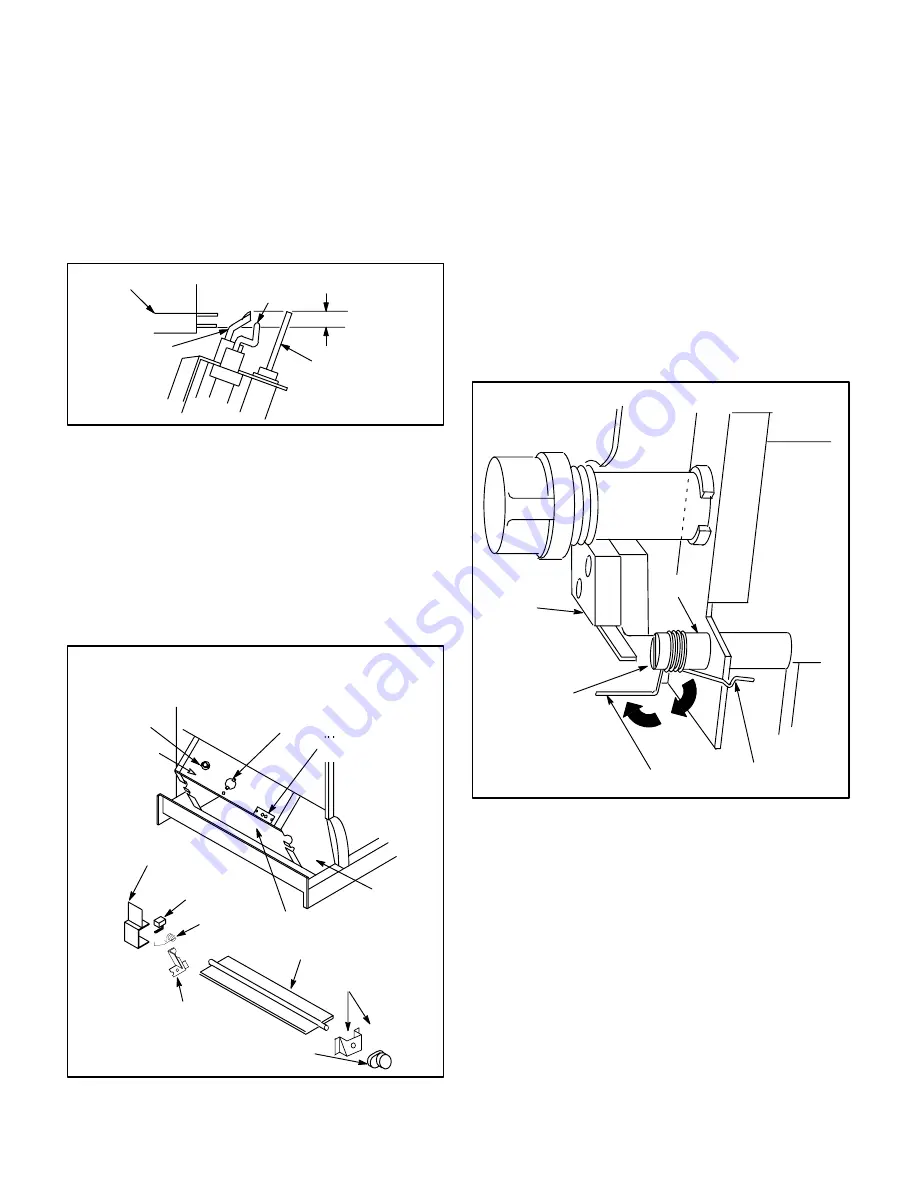

K – Pilot Tube, Ignition Wire and Flame Rod

The pilot tube from the gas valve and the flame sensor

and ignition wires from the electronic ignition control

enter through the top of the burner box to the pilot

burner assembly.

Figure 8 shows the clearance between top of the pilot

burner head and the top of the main burner surface.

IGNITION

WIRE

FLAME SENSOR

WIRE

PILOT ASSEMBLY

5/16”

PILOT

HEAD

FIGURE 8

BURNER

SURFACE

L – Burner Box/Damper Door

The damper motor is located on the right side of the

burner box. On the left side of the burner box, behind a

protective plate is the damper prove switch. Refer to

figure 9. The burner box top is removable on all units.

When there is a call for heat, the damper motor is ener-

gized and damper door opens as the damper motor

axle begins to rotate.

REMOVEABLE

TOP

DAMPER MOTOR/GEAR

PATCH PLATE

PATCH PLATE

SPRING

DAMPER

PROVE SWITCH

PROVE

SWITCH COVER

OBSERVATION PORT

COVER

DAMPER

PILOT PATCH

PLATE

DAMPER

BOX

DAMPER BOX PARTS ARRANGEMENT

(G20RE Units Shown)

DAMPER OPENING

FIGURE 9

ROLL–OUT

SWITCH

M – Damper Prove Switch (S64)

The spring, which is held by a notch in the burner box

frame, activates the damper prove switch as the damp-

er door opens. See figure 10. The axle rotates the

damper door to open position. As the axle turns, the

spring winds backward to make contact with the damp-

er prove switch. The protective cover plate is remov-

able (one screw) and the spring may be unclipped for

service to the damper door or burner box. Spring must

be removed in order to remove the damper door.

After service is complete, the spring must rest snugly

in notch for damper prove switch to function properly.

Do not force door open, damage to the spring and mo-

tor may occur. Take care to open damper door slowly.

Axle rotates

and opens the

door, slot in left

end of axle

pulls spring

back to activate

damper prove

switch.

DAMPER

PROVE

SWITCH

SPRING

SPRING FITS

SNUGLY IN NOTCH

FIGURE 10

AXLE

DAMPER

DOOR

DAMPER PROVE SWITCH ASSEMBLY

MANIFOLD

III – PLACEMENT AND INSTALLATION

Make sure the unit is installed in accordance with

installation instructions and all applicable codes.

IV – START-UP

A – Preliminary and Seasonal Checks

1 – Inspect electrical wiring, both field and factory

installed for loose connections. Tighten as re-

quired.

2 – Check voltage at disconnect switch. Voltage must

be within range listed on the nameplate. If not, con-

sult the power company and have voltage condi-

tion corrected before starting unit.