Page 8

E – Check Manifold Pressure

After line pressure has been checked and adjusted,

check manifold pressure. Move pressure gauge to out-

let pressure tap located on unit gas valve (GV1). See

figure 6 for location of pressure tap on gas valve.

IMPORTANT

For safety, connect a shut-off valve between the

manometer and the gas tap to permit shut off of

gas pressure to the manometer.

The gas valve is factory set and should not require ad-

justment. All gas valves are factory regulated. See

table 5 . See tables 6 and 7 for derated manifold pres-

sure values in high altitude application for natural and

LP gases.

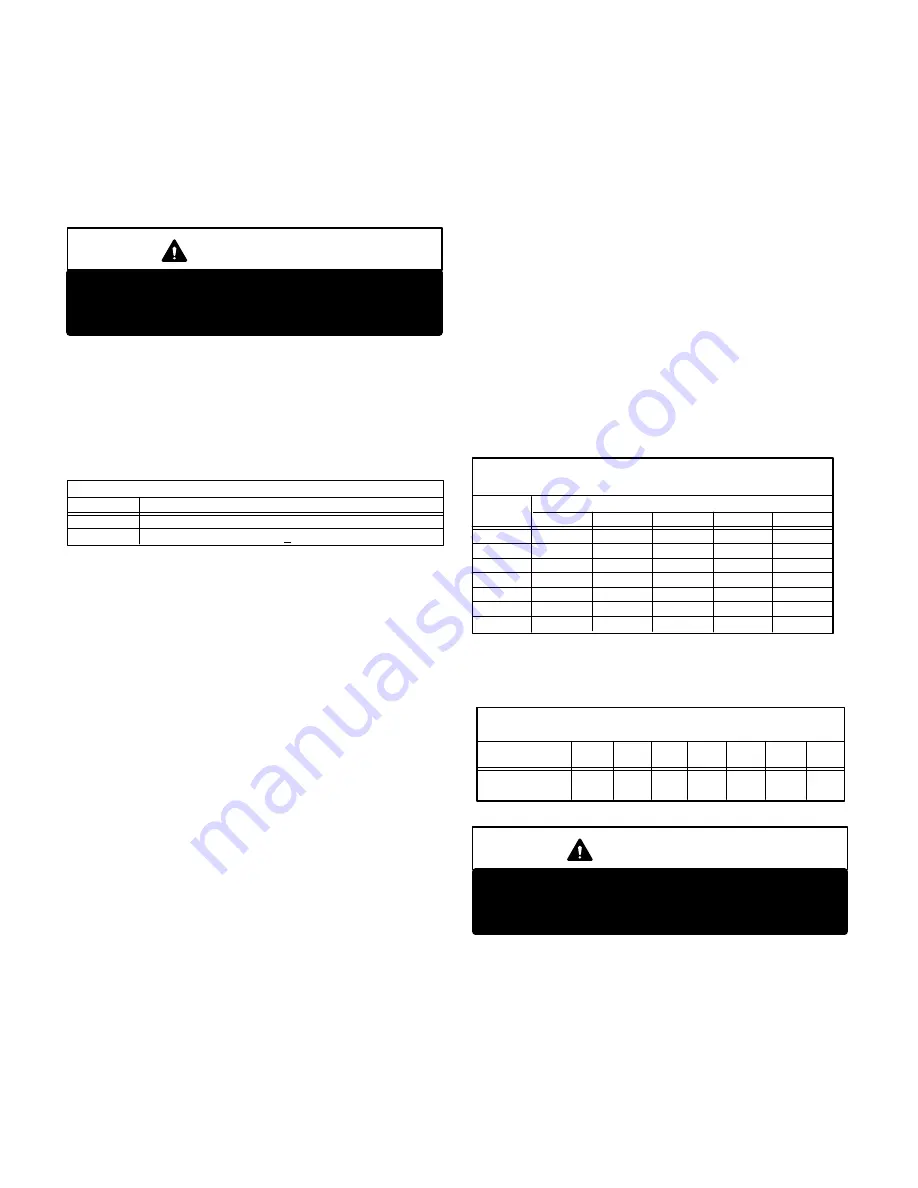

Operating Pressure (outlet) in. W.C.

TABLE 5

GAS VALVE REGULATION

3.5 +0 –0.3

Natural

L.P.

9.5 + 0.5

Unit (Fuel)

Manifold Adjustment Procedure:

1 – Connect a test gauge to outlet pressure tap on gas

valve. Start unit and allow 5 minutes for unit to

reach high fire steady state.

2 – While waiting for the unit to stabilize, notice the

flame. Flame should be stable and should not lift

from burner. Natural gas should burn blue. L.P. gas

should burn mostly blue with some orange

streaks.

3 – After allowing unit to stabilize for 5 minutes, re-

cord manifold pressure and compare to values

given in table 5.

NOTE– Disconnect heating demand as soon as an

accurate reading has been obtained.

F – Proper Gas Flow

To check for proper gas flow to combustion chamber,

determine Btuh input from unit rating plate or table or

the specifications tables on pages 1 and 2. Divide input

rating by Btuh per cubic foot of available gas. Result is

the number of cubic feet per hour required. Determine

flow of gas through gas meter for two minutes . Multi-

ply by 30 to get hourly flow of gas to burner.

NOTE– To obtain accurate reading, shut off all other

gas appliances connected to meter.

G – High Altitude Derate

C.G.A. certified units used in high altitude applications

are factory equipped with modifications that eliminate

the need for manifold pressure adjustment to obtain

proper heat input. Check the unit rating plate to make

sure unit is a high altitude unit.

A.G.A. certified units must be derated when installed at

an elevation of 2,000 ft. (610 m) or more above sea lev-

el. Tables 6 and 7 show the derated manifold pressure

for high altitude operation with both natural and LP/

Propane gas. Operating this appliance at the manifold

pressure specified on the tables will ensure proper unit

heat input at high altitude. Consult your gas utility for

the local natural gas heating value.

NOTE–This is the only permissible field derate for

this appliance.

2.25” wc

Altitude

*Heating Value (Btu/Ft

#

)

(Ft.)

900

950

1000

1050

1100

0

1000

2000

3000

4000

5000

6000

4.32” wc

4.32” wc

3.65” wc

3.35” wc

3.05” wc

2.77” wc

2.50” wc

3.88” wc

3.88” wc

3.30” wc

3.00” wc

2.75” wc

2.48” wc

3.50” wc

3.50” wc

2.95” wc

2.70” wc

2.45” wc

2.25” wc

3.17” wc

3.17” wc

2.70” wc

2.45” wc

2.25” wc

2.89” wc

2.89” wc

2.45” wc

2.25” wc

HIGH ALTITUDE MANIFOLD PRESSURE

DERATE FOR NATURAL GAS UNITS

*Heating value based on atmospheric pressure of 30” mercury

and temperature of 60

°

F (16

°

C).

TABLE 6

_ _

_ _

_ _

_ _

_ _

_ _

ALTITUDE

(Ft.)

MANIFOLD

PRESSURE

HIGH ALTITUDE MANIFOLD PRESSURE

DERATE FOR LP/PROPANE GAS UNITS

0

1000

2000

3000

4000

5000

6000

9.5”

w.c.

8.0”

w.c.

7.2”

w.c.

6.5”

w.c.

5.9”

w.c.

5.3”

w.c.

TABLE 7

9.5”

w.c.

IMPORTANT

For safety, shut unit off and remove manometer as

soon as an accurate reading has been obtained.

Take care to replace pressure tap plug.

H – Flame Signal

Flame signal or microamp is an electrical current which

passes from the ignition control through the sensor

electrode during unit operation. Current passes from

the sensor through the flame to ground to complete a

safety circuit. A 50 microamp DC meter is needed to

check flame signal on the primary ignition control.