Page 11

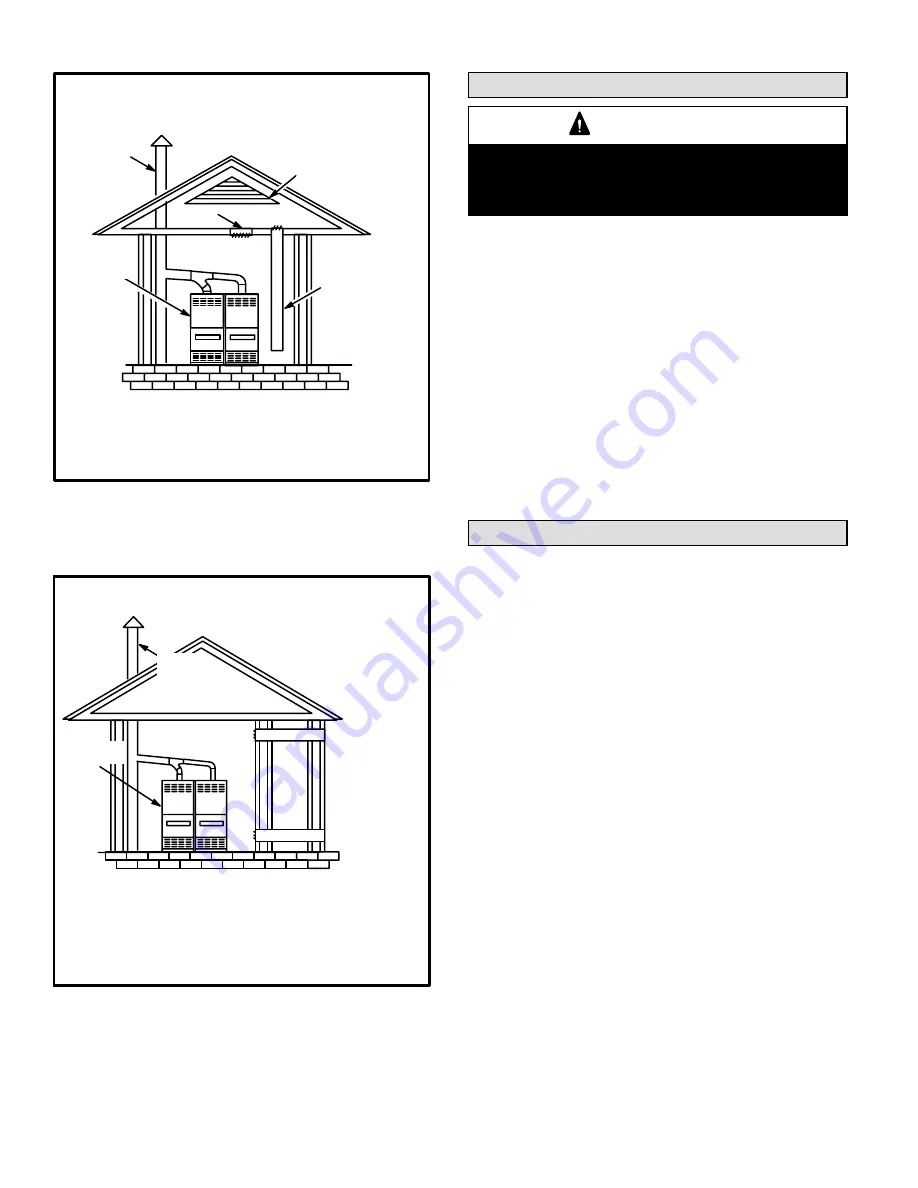

EQUIPMENT IN CONFINED SPACE

ALL AIR FROM OUTSIDE

(All Air Through Ventilated Attic)

CHIMNEY

OR GAS

VENT

OUTLET

AIR

VENTILATION LOUVERS

(Each end of attic)

INLET AIR

(Ends 12 in.

above bottom)

G24−200

FURNACE

NOTE−The inlet and outlet air openings shall each have a

free area of at least one square inch (645 mm

2

) per 4,000

Btu (1.17 kW) per hour of the total input rating of all equip-

ment in the enclosure.

FIGURE 3

EQUIPMENT IN CONFINED SPA

CE

(ALL AIR FROM OUTSIDE)

OUTLET AIR

INLET AIR

CHIMNEY

OR GAS

VENT

G24−200

FURNACE

NOTE−Each air duct opening shall have a free area of at least

one square inch (645 mm

2

) per 2,000 Btu (.59 kW) per hour of

the total input rating of all equipment in the enclosure. If the

equipment room is located against an outside wall and the air

openings communicate directly with the outdoors, each open-

ing shall have a free area of at least one square inch (645 mm

2

)

per 4,000 Btu (1.17 kW) per hour of the total input rating of all

other equipment in the enclosure.

FIGURE 4

Setting Equipment

WARNING

Do not install the furnace on its front or its back. Do-

ing so will adversely affect the operation of the safety

control devices, which could result in personal inju-

ry or death.

The Lennox G24−200 upflow gas furnace can be

installed with rear or bottom return air. If unit is installed

on a platform with bottom return air, furnace/filter box must

be sealed airtight at the platform to ensure proper and safe

operation.

Select a location that allows for required clearances listed

on unit rating plate. Also consider gas supply connections,

electrical supply, vent connection, installation and service

clearances [24 inches (610mm) at unit front] and filter ac-

cessibility.

The furnace must be leveled using shims or leveling bolts

(field provided). The corner gussets provided in the furnace

base will accept leveling bolts.

Return Air Plenum / Filter Box Installation

Return air openings are provided at rear and in bottom of

unit. A return air closure panel is shipped secured to the

rear opening.

A − Bottom Return Air (Refer to figure 5)

1 − Determine the location of the furnace/filter box.

2 − Cut 50-5/8 x 26-1/8 (128.6cm x 66.4cm) opening in the

return air platform.

3 − Fabricate the return air plenum with right angle flanges

and insert into the floor opening.

4 − Remove filter box access door and filters.

5 − Apply adhesive-backed foam tape to the bottom of the

filter box all around the opening. Position the filter box

over the return air plenum. Fasten as required using

self-tapping screws provided.

Make sure there is an air tight seal between the

platform/return air plenum and filter box.

6 − Apply adhesive-backed foam to the top of the filter box

all around the opening. Place furnace over the filter box

with sides and rear of furnace and filter box flush. Fas-

ten as required.

Make sure there is an air tight seal between the fur-

nace and the filter box.