Page 12

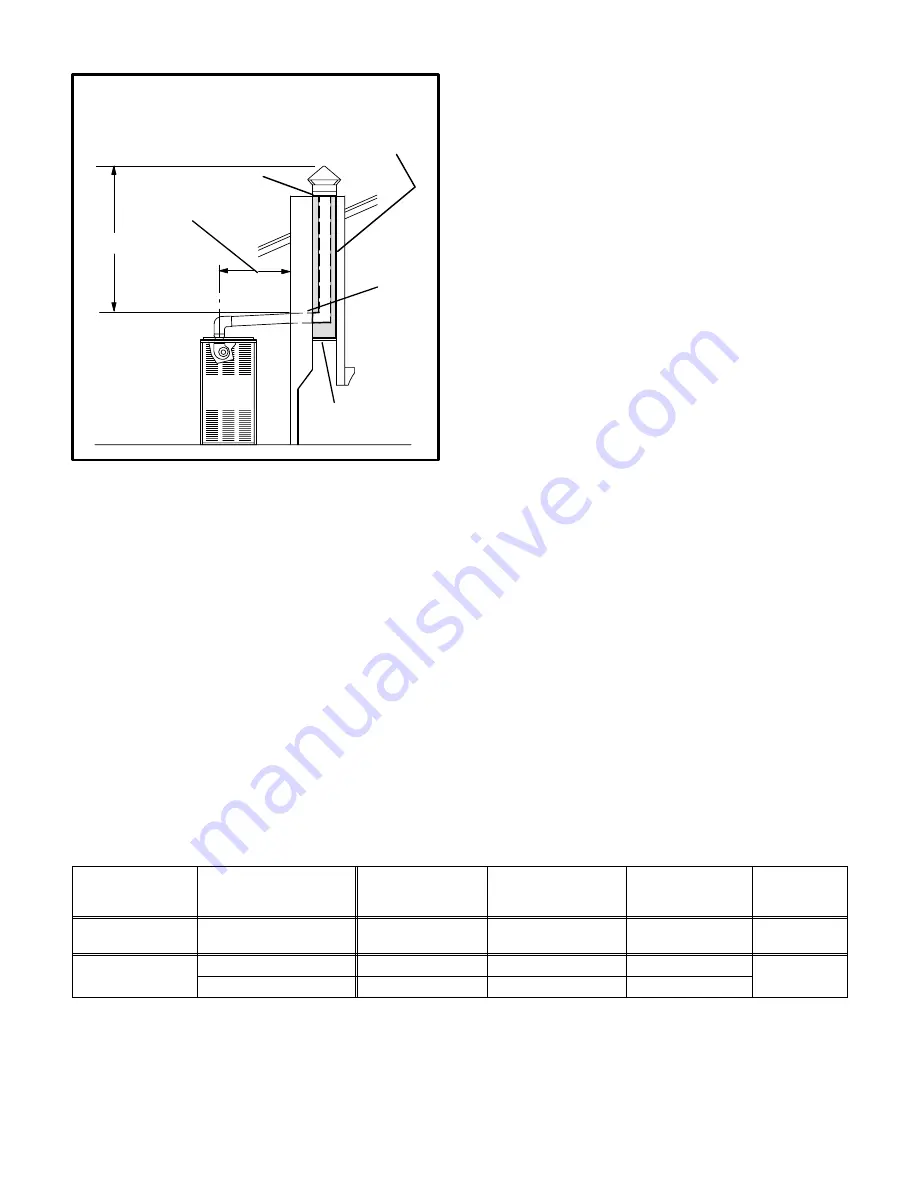

VENTING USING METAL-LINED

EXTERIOR MASONRY CHIMNEY

1.5m (5 FT.)

MINIMUM

SEALED

PERMANENTLY SEALED

FIREPLACE OPENING

EXTERIOR CHIMNEY WITH TWIN-WALLED LINER OR

INSULATED (FLEXIBLE) SINGLE-WALLED LINER.

Note: See the regulations that are in force in the

country of installation for flue connector sizing.

MIN. LENGTH - AS SHORT AS PRACTICAL

MAXIMUM LENGTH - SEE NOTE AT SIDE

HIGHEST FLUE

CONNECTOR POINT

FIGURE 15

Do not install a manual damper, barometric draught reguĆ

lator, or flue restrictor between the furnace and the chimĆ

ney. Remove any such existing devices.

If twin-wall flue is used inside a chimney, no other apĆ

pliance can be vented into the chimney. Outer wall of twin-

wall flue pipe must not be exposed to flue products.

If a flexible single-walled liner is used in a masonry chimĆ

ney, the liner must be insulated. Insulation for the flexible

vent pipe must be an encapsulated fiberglass sleeve recĆ

ommended by the flexible vent pipe manufacturer. See

figure 15.

If twin-wall flue or an insulated flexible vent pipe cannot be

used as liners, the chimney must be rebuilt to accommoĆ

date one of these methods or some alternate approved

method must be found to vent the appliance.

The space between the liner and the chimney wall

should NOT be insulated with puffed mica or any othĆ

er loose granular insulating material.

When inspection reveals that an existing chimney is not

safe for the intended purpose, it shall be rebuilt to conform

to nationally recognized standards. The chimney pasĆ

sageway must be checked periodically to ensure that it is

clear and free of obstructions.

HORIZONTAL FLUE USING METAL FLUE PIPE

These instructions should be used as a guide and do not

supersede local codes in any way. Size and install the

G24MCE horizontal flue according to the national and loĆ

cal codes and regulations which are in effect in the counĆ

try of installation.

The following are specific requirements for installation of

the G24MCE furnace:

1 - Install first flue connector elbow a minimum of

152mm (6 in.) from the furnace flue outlet.

2 - If the flue is sloped upward as it is routed away from

the furnace, the furnace must be protected from the

condensate produced in the flue.

3 - The flue system must be sealed (all joints must be

sealed), as positive pressure can occur in the flue.

4 - A 152mm (6 in.) clearance must be maintained to all

combustibles when single-walled flue pipe is used. A

25mm (1 in.) clearance to all combustibles must be

maintained when twin-walled flue pipe is used.

5 - If single-walled flue is used, fasten the flue adapter

to the flue outlet of the furnace and the flue connector

to the flue adapter using one or two corrosion-resisĆ

tant sheet metal screws. If twin-walled flue pipe is

used, fasten to the adapter according to manufacturĆ

er's instructions.

6 - Support flue as required by the regulations in force.

7 - See table 3 for flue diameter, equivalent lengths and

termination allowed.

8 - The tee termination shown in figures 16 and 17 is the

only acceptable termination.

TABLE 3

HORIZONTAL FLUE PIPE SIZING

MODEL SIZE

UNIT ORIENTATION

MINIMUM FLUE PIPE

DIAMETER mm (in.)

MINIMUM FLUE

EQUIVALENT

LENGTH* m (ft.)

MAXIMUM FLUE

EQUIVALENT

LENGTH* m (ft.)

TERMINATION

TEE

45

HORIZONTAL

UPFLOW / DOWNFLOW

102 (4)

3 (10)

9.2 (30)

1

HORIZONTAL

102 (4)

3 (10)

9.2 (30)

60/75/100/120/140

UPFLOW / DOWNFLOW

102 (4)

3 (10)

13.7 (45)

1

*One 90

5

elbow equals 1.5 m (5 ft.) of straight pipe. One 45

5

elbow equals 0.75 m (2.5 ft.) of straight pipe.

![Roberts Gorden Combat UHD[S] 150-400 Specifications preview](http://thumbs.mh-extra.com/thumbs/roberts-gorden/combat-uhd-s-150-400/combat-uhd-s-150-400_specifications_1469644-1.webp)