Page 8

TABLE 1

NONCOMBUSTIBLE FLOOR OPENING

UNIT

Front to Rear

Side to Side

in

mm

in

mm

G24MCE-45/60/75

502

388

NOTE-Floor opening dimensions listed are 6mm (1/4") larger

than unit openings.

19-3/4

15-1/4

G24MCE-100/120

502

477

19-3/4

18-3/4

G24MCE-140

502

546

19-3/4

21-1/2

2 - Flange warm air plenum and lower into opening.

3 - Set unit over plenum.

4 - Check to see that an adequate seal is made.

B-Installation on Combustible Flooring

1 - When unit is installed on a combustible floor, an addiĆ

tive base (ordered separately) must be installed beĆ

tween the furnace and the floor. See table 2 for openĆ

ing size to cut in the floor.

TABLE 2

ADDITIVE BASE FLOOR OPENING

UNIT

Front to Rear

Side to Side

in

mm

in

mm

G24MCE-45/60/75

556

440

NOTE-Floor opening dimensions listed are 1/4" (6mm) larger

than additive base openings.

21-7/8

17-5/16

G24MCE-100/120

556

528

21-7/8

20-3/4

G24MCE-140

556

597

21-7/8

23-1/2

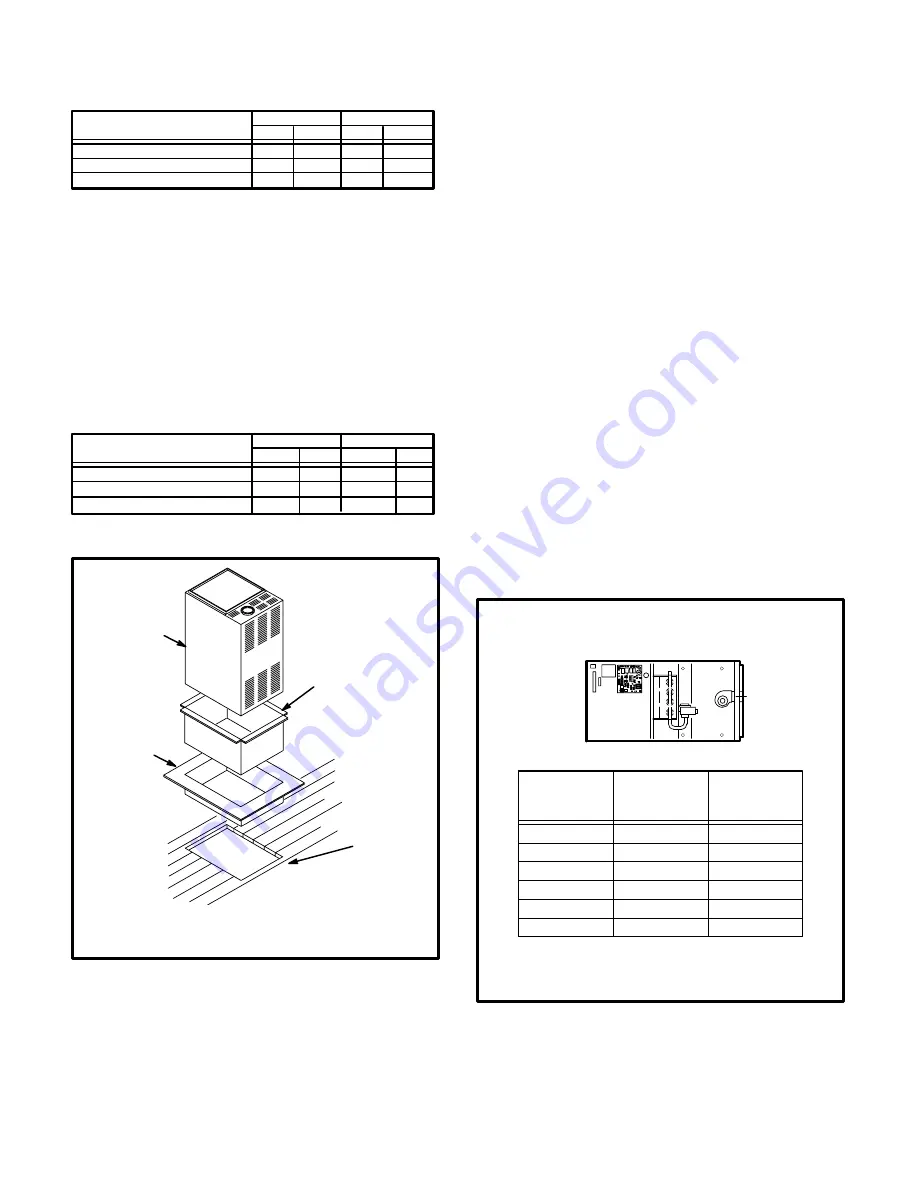

G24MCE UNIT

SUPPLY AIR

PLENUM

ADDITIVE

BASE

PROPERLY

SIZED FLOOR

OPENING

1. Cut correct size floor opening

2. Set additive base into opening.

3. Set supply air plenum into additive base.

4. Set unit.

FIGURE 8

2 - After opening is cut, set the additive base into

opening.

3 - Check glass fibre strips on additive base to make

sure they are properly glued and positioned.

4 - Lower supply air plenum into additive base until pleĆ

num flanges seal against glass fibre strips.

5 - Set unit on additive base so unit flanges drop into pleĆ

num. Refer to figure 8.

NOTE-Be careful not to damage glass fibre strips.

Check for tight seal.

C-Installation on Cooling Cabinet

1 - Refer to reverse flow coil installation instructions for

correctly sized opening in floor and installation of

cabinet.

2 - When cooling cabinet is in place, install furnace so

flanges drop inside cabinet opening.

3 - Seal cabinet and check for air leakage.

HORIZONTAL APPLICATIONS

The Lennox G24MCE furnace can be installed in horizonĆ

tal applications in either upflow or downflow configuration

(See figure 6). It is preferable to install the unit in the stanĆ

dard upflow configuration, if possible, because the vent

pipe will not interfere with service access for fan.

The unit

cannot be installed on its back.

Filter rack is provided. Adjustable rack can be installed

flush with cabinet edges.

Allow for clearances to combustible materials as indicated

on the unit rating plate. Minimum clearances for cupboard

or alcove installations are shown in

figure 9.

HORIZONTAL APPLICATION

INSTALLATION CLEARANCES

VENT

CONNECTOR

TYPE

SINGLE WALL

TWIN WALL

TOP

25mm (1 in.)

25mm (1 in.)

*FRONT

51mm (2 in.)

51mm (2 in.)

BACK

SIDES

FLUE

152mm (6 in.)

BOTTOM

TOP

RIGHT

SIDE

LEFT

SIDE

*Front clearance in alcove installation must be a miniĆ

mum of 610mm (24 in.) for service access.

**On combustible floor with non-combustible protection.

NC - Non-Combustibles

BOTTOM

**NC

**NC

25mm (1 in.)

25mm (1 in.)

51mm (2 in.)

51mm (2 in.)

25mm (1 in.)

FIGURE 9