Page 10

magnet rotor it does not need brushes like conventional

D.C. motors. Internal components are shown in figure 10.

The stator windings are split into three poles which are

electrically connected to the controller. This arrangement

allows motor windings to turn on and off in sequence

by the controller.

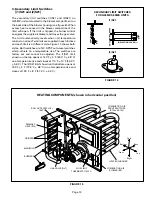

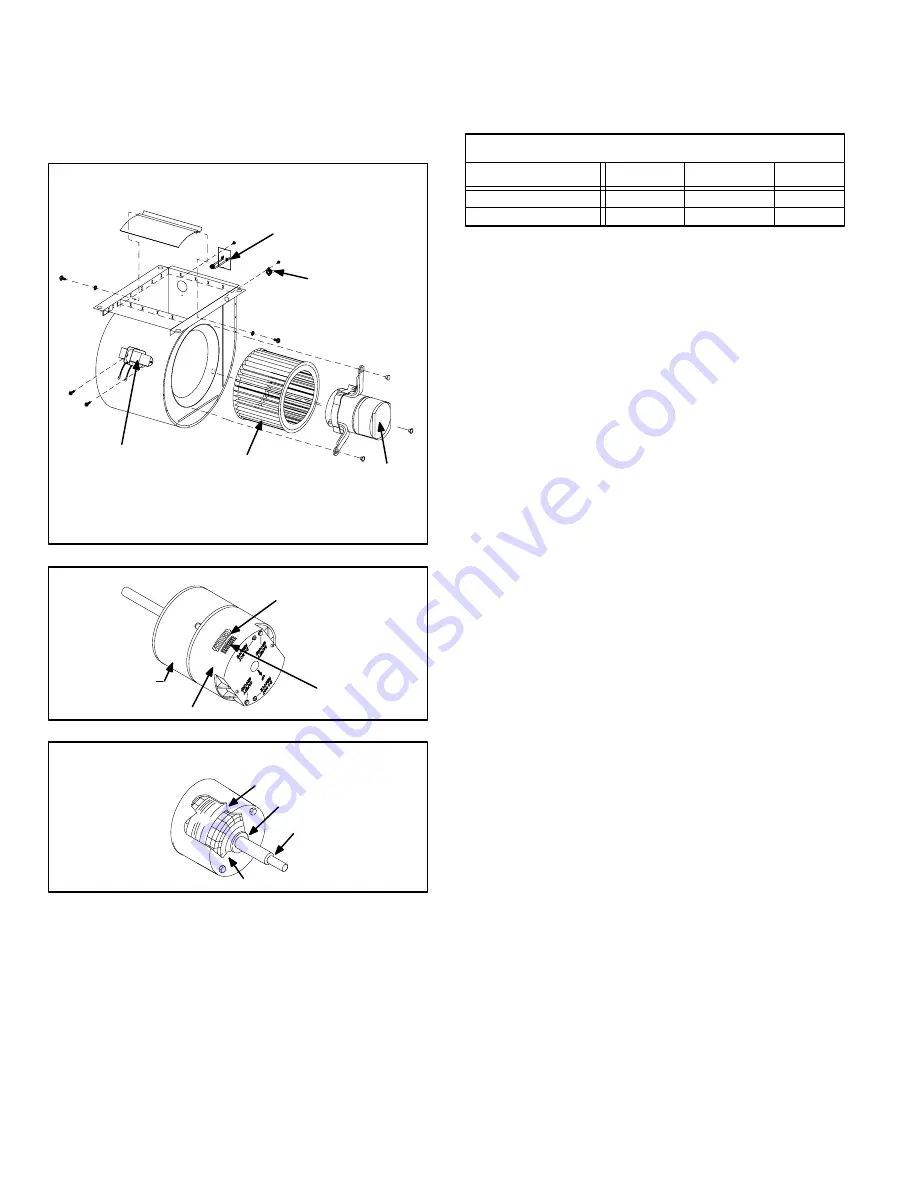

FIGURE 8

SUPPLY AIR BLOWER

AND SECONDARY LIMITS

BLOWER

MOTOR (B6)

To Remove Blower From Unit: Remove Bolts and

Wiring Jackplugs. Then Slide Out Front of Unit.

COIL

CHOKE (L13)

SECONDARY

LIMITS [(1)S21]

BLOWER

WHEEL

SECONDARY

LIMITS [(2)S21]

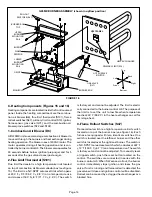

FIGURE 9

G25MV BLOWER MOTOR B3

MOTOR

CONTROLLER

SHAFT

J49

J48

G25MV BLOWER MOTOR COMPONENTS

FIGURE 10

STATOR

(WINDINGS)

OUTPUT

SHAFT

BEARING

ROTOR

A solid-state controller is permanently attached to

the motor. The controller is primarily an A.C. to D.C.

converter. Converted D.C. power is used to drive the

motor. The controller contains a microprocessor

which monitors varying conditions inside the motor

(such as motor workload).

The controller uses sensing devices to sense what posi-

tion the rotor is in at any given time. By sensing the posi-

tion of the rotor and then switching the motor windings

on and off in sequence, the rotor shaft turns the blower.

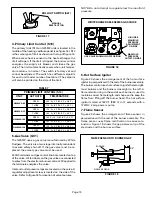

G25MV series blower motor ratings are listed in table

6. All G25MV blower motors use single phase power.

An external run capacitor is not used. The motor uses

permanently lubricated ball-type bearings.

TABLE 6

ELECTRONICALLY CONTROLLED BLOWER MOTOR

CCW ROTATION

Unit

Volts

Phase

HP

G25MV3

120

1

1

1/2

1

G25MV5

120

Internal Operation

Each time the controller switches a stator winding (figure

10) on and off, it is called a “pulse.” The length of time

each pulse stays on is called the “pulse width.” By varying

the pulse width (figure 11), the controller varies motor

speed (called “pulse-width modulation”). This allows for

precise control of motor speed and allows the motor to

compensate for varying load conditions as sensed by the

controller. In this case, the controller monitors the static

workload on the motor and varies motor rpm in order to

maintain constant airflow (cfm).

The motor is equipped with 11 incremental taps which are

driven by the integral controller. The controller is capable

of controlling three of the 11 taps.

The motor controller is driven by the VSP2. The VSP2

receives its demand (PWM signal or fixed 24 VAC or

VDC signal) from optional controls such as the Harmony

zone control system, Efficiency Plus Humidity Control

(CCB1) or a conventional thermostat.

Motor rpm is continually adjusted internally to maintain

constant static pressure against the blower wheel. The

controller monitors the static work load on the motor and

motor amp-draw to determine the amount of rpm adjust-

ment. Blower rpm may be adjusted any amount in order

to maintain a constant cfm as shown in Blower Ratings

Tables. The amount of adjustment is determined by the

incremental taps which are used and the amount of motor

loading sensed internally. The cfm remains relatively

stable over a broad range of static pressure. Since the

blower constantly adjusts rpm to maintain a specified

cfm, motor rpm is not rated. Hence, the terms “blower

speed” and “speed tap” in this manual, on the unit wiring

diagram and on blower B3 refer to blower cfm regardless

of motor rpm.

When Harmony is used, speed taps are overridden and a

PWM signal generated by the Harmony controller contin-

uously varies motor speed based upon zone demands.

Initial Power Up

When line voltage is applied to B3, there will be a large

inrush of power lasting less than 1/4 second. This inrush

charges a bank of DC filter capacitors inside the controller.

If the disconnect switch is bounced when the disconnect

is closed, the disconnect contacts may become welded.

Try not to bounce the disconnect switch when applying

power to the unit.