Page 4

6 -

White Rodgers 36E Gas Valve -

Turn knob on gas

valve 180

°

either way to

OFF

. See figure 1.

7 - Wait five minutes to clear out any gas. If you then smell

gas,

STOP

! Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's instructions.

If you do not smell gas go to next step.

WHITE RODGERS 36E SERIES GAS VALVE

GAS VALVE SHOWN IN OFF POSITION

p M

C

HI

FIGURE 2

8 -

White Rodgers 36E Gas Valve -

Turn knob on gas

valve 180

°

either way to

ON

.

9 - Replace the access panel.

10 - Turn on all electrical power to to the unit.

11 - Set the thermostat to desired setting.

NOTE – When unit is initially started, steps 1 through 11

may need to be repeated to purge air from gas line.

12 - If the appliance will not operate, follow the instrucĆ

tions Turning Off Gas to Unit" and call your service

technician or gas supplier.

Turning Off Gas to Unit

1 - Set the thermostat to the lowest setting.

2 - Turn off all electrical power to the unit if service is to

be performed.

3 - Remove the access panel.

4 -

White Rodgers 36E Gas Valve -

Turn knob on gas

valve 180

°

either way to

ON

.

5 - Replace access panel.

Two–Stage Operation

The G27M is a two-stage gas-fired furnace, which can be

controlled by either a two-stage or single-stage room

thermostat.

The two-stage thermostat monitors the room temperature

and sends a signal to the G27M furnace when the temperĆ

ature falls below the desired setpoint. The furnace is then

turned on at low fire (first stage). If the room temperatures

continues to fall, the thermostat sends a signal to turn on

the unit at high fire (second stage).

When a single-stage thermostat is being used to control

the operation of the G27M furnace, the unit can either opĆ

erate on high fire (second stage) at all times or the unit can

be made to start on low fire (first stage) and automatically

switch to high fire (second stage) after a time delay, if the

demand is not satisfied on low fire (first stage).

NOTE – For more details on available options and for unit

adjustment, contact the Lennox Technical Support De-

partment.

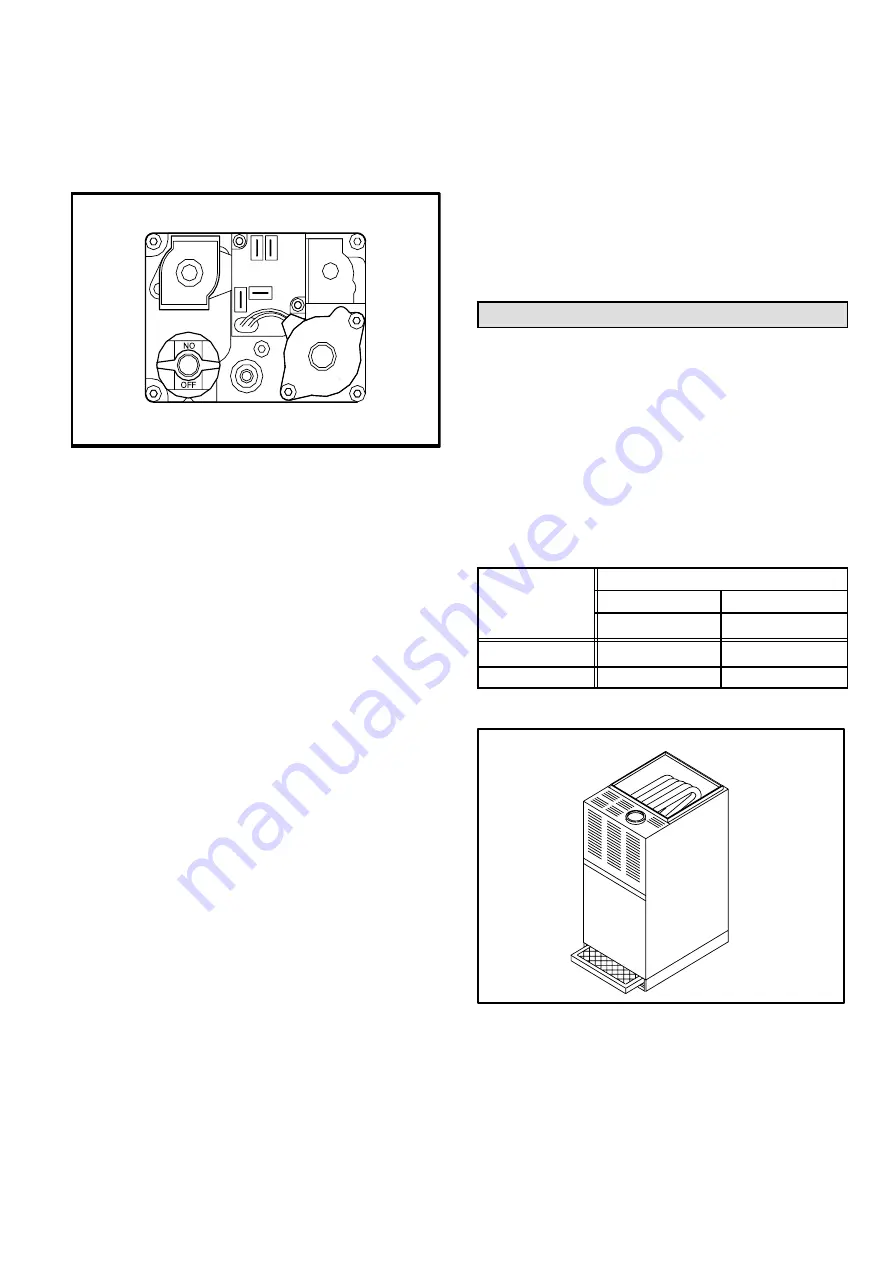

Filters

G27M series units are equipped with external filters

which should be inspected monthly and replaced when

necessary to assure proper furnace operation. See

table 1 for filter sizes. Replacement filters used with

G27M-60/75 units must have a minimum velocity ratĆ

ing of 400 FPM. Replacement filters used with

G27M-100/120 units require a minimum velocity rating

of 625 FPM. Figures 3, 4, and 5 show possible filter

locations.

TABLE 1

FILTER SIZE

MODEL NUMBER

UPFLOW

DOWNFLOW

1 FILTER

2 FILTERS

G27M-45/60/75

16 in. X 20 in. X 1 in. 16 in. X 20 in. X 1 in.

G27M-100/120/140 20 in. X 20 in. X 1 in. 16 in. X 20 in. X 1 in.

UPFLOW FURNACE BOTTOM RETURN AIR

FIGURE 3

All manuals and user guides at all-guides.com