Page 10

Exhaust Piping

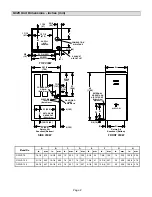

1 - Cement exhaust piping into flue collar socket located

on the left side of the top cap.

2 - All horizontal runs of exhaust pipe must slope back

toward the unit. A minimum of 1/4 inch (6 mm) drop

for each 12 inches (305 mm) of horizontal run is manĆ

datory for drainage. Horizontal runs of exhaust pipĆ

ing must be supported every 5 feet (1.52 m) using

hangers.

NOTE - Exhaust piping should be checked carefully

to make sure there are no sags or low spots.

NOTE - Exhaust piping must be insulated with 1/2

inch (13 mm) Armaflex or equivalent when run

through unheated space. Do not leave any area of

exhaust pipe open to outside air; exterior exhaust

must be insulated with 1/2 inch (13 mm) Armaflex or

equivalent.

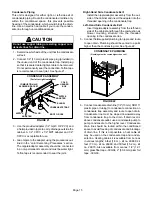

CAUTION

Do not discharge exhaust into an existing stack or

stack that also serves another gas appliance. If verĆ

tical discharge through an existing unused stack is

required, insert PVC pipe inside the stack until the

end is even with the top or outlet end of the metal

stack.

CAUTION

The exhaust vent pipe operates under positive

pressure and must be completely sealed to pre-

vent leakage of combustion products into the livĆ

ing space.

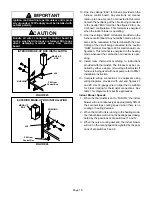

Removal of Unit from Common Venting System

In the event that an existing furnace is removed from a

venting system commonly run with separate gas apĆ

pliances, the venting system may be too large to properly

vent the remaining attached appliances. The following

test should be conducted while all appliances (both in opĆ

eration and those not in operation) are connected to the

common venting system. If the venting system has been

installed improperly, corrections must be made as outĆ

lined in the previous section.

1 - Seal any unused openings in the common venting

system.

2 - Visually inspect the venting system for proper size

and horizontal pitch and determine there is no blockĆ

age or restriction, leakage, corrosion or other defiĆ

ciencies which could cause an unsafe condition.

3 - Close all building doors and windows, and all doors

between the space in which the appliances remainĆ

ing connected to the common venting system are loĆ

cated and other spaces of the building. Turn on

clothes dryers and any appliances not connected to

the common venting system. Turn on any exhaust

fans, such as range hoods and bathroom exhausts,

so they will operate at maximum speed. Do not operĆ

ate a summer exhaust fan. Close fireplace dampers.

4 - Follow the lighting instructions. Place the appliance

being inspected in operation. Adjust thermostat so

appliance will operate continuously.

5 - Test for spillage at the draft hood relief opening after

5 minutes of main burner operation. Use the flame of

match or candle, or smoke from a cigarette or cigar,

or a draft gauge.

6 - After determining that each appliance remaining

connected to the common venting system properly

vents when tested as indicated in step 3, return

doors, windows, exhaust fans, fireplace dampers

and any other gasĆburning appliance to their preĆ

vious condition of use.

7 - If improper venting is observed during any of the

above tests, the common venting system must be

corrected. The common venting system should be

resized to approach the minimum size as deterĆ

mined by using the appropriate tables in appendix G

in the current standards of the National Fuel Gas

Code ANSI Z223-1 in the USA, and the appropriate

Category 1 Natural Gas appliances venting sizing

tables in the current standard of the CAN/

CGA-B149.1 in the Natural Gas Installation Code in

Canada.

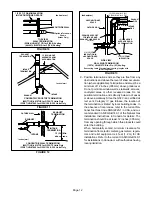

Intake and Exhaust Piping Terminations

Intake and exhaust pipes may be routed either horizontalĆ

ly through an outside wall or vertically through the roof. In

attic or closet installations, vertical termination through

the roof is preferred. Figures 8 through 20 show typical

terminations.

1 - Use recommended piping materials for both intake

and exhaust piping.

2 - Secure all joints, including drain leg, gas-tight using

approved cement.

3 - Piping diameters should be determined according

to length of pipe run. See table 5. Locate intake pipĆ

ing upwind (prevailing wind) from exhaust piping.

To avoid recirculation of exhaust gas on roof terĆ

minations, end of exhaust pipe must be higher than

intake pipe.

Exhaust and intake exits must be in same pressure

zone. Do not exit one through the roof and one on the

side. Also, do not exit the intake on one side and the

exhaust on another side of the house or structure.