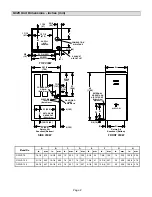

Page 11

4 - Intake and exhaust pipes should be placed as close

together as possible at termination end (refer to ilĆ

lustrations). Maximum separation is 3 inches (76

mm) on roof terminations and 6 inches (152 mm) on

side wall terminations.

5 - Exhaust piping must terminate straight out or up as

shown. In rooftop applications, a 2 inch X 1-1/2 inch

reducer for 2 inch venting, 3 inch x 2 inch reducer for

3 inch venting must be used on the exhaust piping at

the point where it exits the structure to improve the

velocity of exhaust away from the intake piping.

On roof terminations, the intake piping should termiĆ

nate straight down using two 90

°

elbows. See figure 8.

FIGURE 8

ROOF TERMINATION KIT

(15F75) LB-49107CC for 2 (51) Venting

(44J41) LB-65678A for 3 (76) Venting

UNCONDITIONED

ATTIC SPACE

1/2 (13) FOAM

INSULATION IN

UNCONDITIONED

SPACE

3 x 2 (76 x 51) OR

2 x 1-1/2 (51 x 38)

PVC REDUCER

3 (76) MAX.

12 (305) ABOVE

AVERAGE SNOW

ACCUMULATION

3 (76) OR

2 (51) PVC

PROVIDE SUPPORT

FOR INTAKE AND

EXHAUST LINES

8 (203) MIN

Inches (mm)

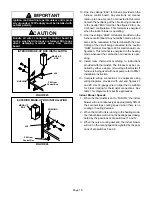

IMPORTANT

Do not use screens or perforated metal in intake

and exhaust terminations. Doing so will cause

freeze-ups and may block the terminations.

NOTE - If winter design temperature is below 32°F (0°C),

exhaust piping must be insulated with 1/2 inch (13 mm),

Armaflex or equivalent when run through unheated

space. Do not leave any surface area of exhaust pipe

open to outside air; exterior exhaust pipe must be insuĆ

lated with 1/2 inch (13 mm) Armaflex or equivalent. In exĆ

treme cold climate areas, 3/4 inch (19 mm) Armaflex or

equivalent is recommended. Insulation on outside runs of

exhaust pipe must be painted or wrapped to protect inĆ

sulation from deterioration.

NOTE - During extremely cold temperatures, below

approximately 20°F (6.67°C), units with long runs of

vent pipe through unconditioned space, even when inĆ

sulated, may form ice in the exhaust termination that

prevents the unit from operating properly. Longer run

times of at least 5 minutes will alleviate most icing probĆ

lems. Also, a heating cable may be installed on exhaust

piping and termination to prevent freezeĆups. Heating

cable installation kit is available from Lennox. See ConĆ

densate Piping section for part numbers.

NOTE - Avoid recirculation of exhaust back into the inĆ

take pipe.

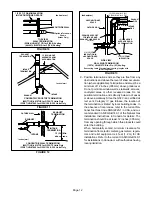

6 - On field-supplied terminations for side wall exits, exĆ

haust piping should extend a maximum of 12 inches

(305 mm) beyond the outside wall. Intake piping

should be as short as possible. See figure 9.

FIGURE 9

1/2 (13) ARMAFLEX

INSULATION IN

UNCONDITIONED SPACE

2 (51) PVC

1-1/2 (38) PVC

12 (305) MIN.

2 X 1-1/2

(51 x 38)

PVC REDUCER

1/2 (13) ARMAFLEX

INSULATION

6 (152)

MAXIMUM

2 (51) PVC

COUPLING

8 (203)

MINIMUM

OUTSIDE

WALL

Inches (mm)

TOP VIEW

WALL RING KIT

(15J74) LB-49107CB for 2 (50.8) Venting

7 - On field-supplied terminations, a minimum separaĆ

tion distance between the end of the exhaust pipe

and the end of the intake pipe is 8 inches (203 mm).

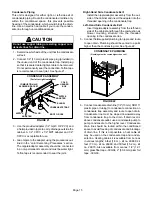

8 - If intake and exhaust piping must be run up a side

wall to position above snow accumulation or other

obstructions, the piping must be supported every 3

feet (.91 m) as shown in figure 14. Refer to figures 13

and 15 for proper piping method. WTK wall terminaĆ

tion kit must be extended for use in this application.

See figure 18 or use kit WTKX shown in figure 19.

When exhaust and intake piping must be run up an

outside wall, the exhaust piping is reduced to 1 1/2

inches (38 mm) after the final elbow. The intake pipĆ

ing may be equipped with a 90

°

elbow turndown. UsĆ

ing turn-down will add 5 feet (1.5 m) to the equivalent

length of the pipe.