Page 15

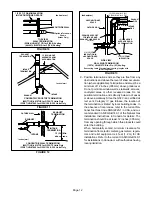

Condensate Piping

This unit is designed for either right- or left-side exit of

condensate piping. Route the condensate drainline only

within the conditioned space: this prevents possible

freezing of the condensate, which would block the drain-

line. Use an electric heat cable if you route the conden-

sate line through unconditioned areas.

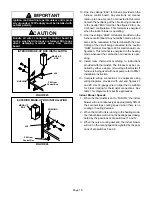

CAUTION

Do not use copper tubing or existing copper conĆ

densate lines for drain line.

1 - Determine which side of the unit that the condensate

will exit.

2 - Connect 1/2" (13 mm) plastic pipe plug (provided) in

the unused end of the condensate trap. Install plug

so that it is sealed water tight yet able to be removed.

Do not permanently seal the connection. Teflon tape

is recommended to seal joint. See figure 21.

CONDENSATE ASSEMBLY

(For left or right installation)

FIGURE 21

COLD

HEADER

BOX

NIPPLE

ADAPTER

ADAPTER

NIPPLE

PLUG

COMBUSTION AIR

BLOWER BRACKET

CONDENSATE TRAP

ELBOW

BOOT OR CAP

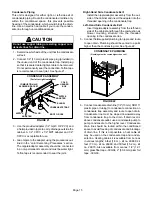

3 - Use the provided adapter (1/2" mpt X 3/4" PVC) and

a field-provided nipple to carry drainage outside the

cabinet. A 1/2" CPVC x 1/2" MPT adapter and 1/2"

CPVC is acceptable for use.

4 - Glue nipple to the adapter using the procedures out-

lined in the Joint Cementing Procedures" section.

The nipple/adapter assembly should be connected

in a non-permanent manner and must be water tight.

Teflon tape is recommended to seal the joint.

Right-Hand Side Condensate Exit:

Install the nipple/adapter assembly from the outĆ

side of the cabinet and insert the adapter into the

threaded opening in the condensate trap.

Left-Hand Side Condensate Exit:

Insert nipple/adapter assembly from the left-hand

side of the cabinet and through the combustion air

blower mounting structure into the threaded

opening in the condensate trap.

5 - Connect field-supplied plumbing to nipple and route

to open drain. Plumbing should be vented to a point

higher than the condensing coil. See figure 22.

FIGURE 22

CONDENSATE PLUMBING

(Plumbing must be vented higher than coil.)

6 - Connect condensate drain line [1/2" (13 mm) SDR 11

plastic pipe or tubing] to condensate connection on

condensate trap assembly and route to open drain.

Condensate line must be sloped downward away

from condensate trap to the drain. If drain level is

above condensate outlet, use a condensate pump to

pump condensate to the higher level. Condensate

drain line should be routed within the conditioned

space to avoid freezing of condensate and blockage

of drain line. If this is not possible, a heat cable kit

may be used on the condensate trap and condenĆ

sate line. Heating cable kit is available from Lennox

in various lengths; 6 feet (1.8 m) - kit no. 26K68; 24

feet (7.3 m) - kit no. 26K99; and 50 feet (15.2 m) - kit

no. 26K70. Also available from Lennox: 1/2" (12.7

mm) glass fiber tape - 39G04; 2" (50.8 mm) plum foil

tape - 39G03.