Page 17

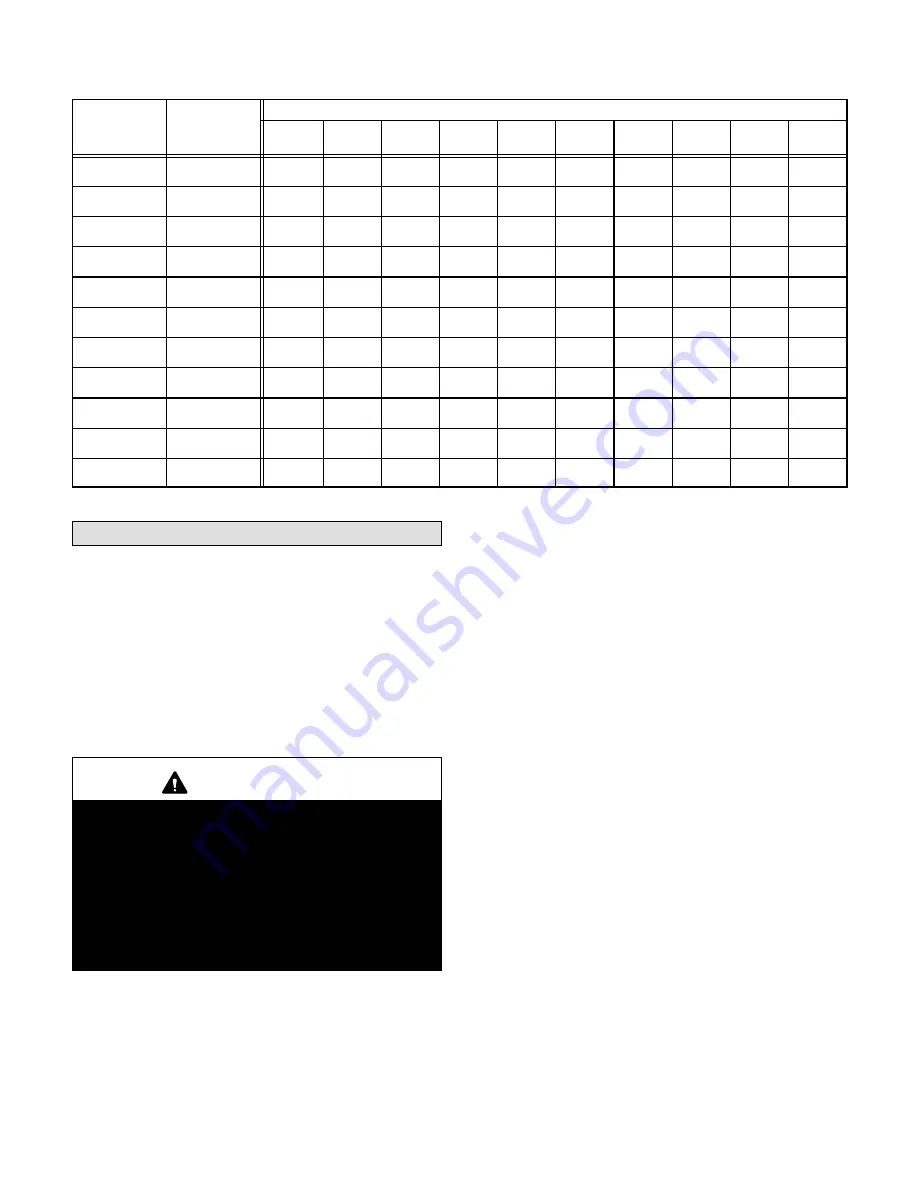

TABLE 6

GAS PIPE CAPACITY - ft.

3

/hr (m

3

/hr)

Nominal

Internal

Length of Pipe-Feet (m)

Nominal

Iron Pipe Size

-Inches(mm)

Internal

Diameter

-Inches(mm)

10

(3.048)

20

(6.096)

30

(9.144)

40

(12.192)

50

(15.240)

60

(18.288)

70

(21.336)

80

(24.384)

90

(27.432)

100

(30.480)

1/4

(6.35)

.364

(9.246)

43

(1.13)

29

(.82)

24

(.68)

20

(.57)

18

(.51)

16

(.45)

15

(.42)

14

(.40)

13

(.37)

12

(.34)

3/8

(9.53)

.493

(12.522)

95

(2.69)

65

(1.84)

52

(1.47)

45

(1.27)

40

(1.13)

36

(1.02)

33

(.73)

31

(.88)

29

(.82)

27

(.76)

1/2

(12.7)

.622

(17.799)

175

(4.96)

120

(3.40)

97

(2.75)

82

(2.32)

73

(2.07)

66

(1.87)

61

(1.73)

57

(1.61)

53

(1.50)

50

(1.42)

3/4

(19.05)

.824

(20.930)

360

(10.19)

250

(7.08)

200

(5.66)

170

(4.81)

151

(4.28)

138

(3.91)

125

(3.54)

118

(3.34)

110

(3.11)

103

(2.92)

1

(25.4)

1.049

(26.645)

680

(19.25)

465

(13.17)

375

(10.62)

320

(9.06)

285

(8.07)

260

(7.36)

240

(6.80)

220

(6.23)

205

(5.80)

195

(5.52)

1-1/4

(31.75)

1.380

(35.052)

1400

(39.64)

950

(26.90)

770

(21.80)

660

(18.69)

580

(16.42)

530

(15.01)

490

(13.87)

460

(13.03)

430

(12.18)

400

(11.33)

1-1/2

(38.1)

1.610

(40.894)

2100

(59.46)

460

(41.34)

1180

(33.41)

990

(28.03)

900

(25.48)

810

(22.94)

750

(21.24)

690

(19.54)

650

(18.41)

620

(17.56)

2

(50.8)

2.067

(52.502)

3950

(111.85)

2750

(77.87)

2200

(62.30)

1900

(53.80)

1680

(47.57)

1520

(43.04)

1400

(39.64)

1300

(36.81)

1220

(34.55)

1150

(32.56)

2-1/2

(63.5)

2.469

(67.713)

6300

(178.39)

4350

(123.17)

3520

(99.67)

3000

(84.95)

2650

(75.04)

2400

(67.96)

2250

(63.71)

2050

(58.05)

1950

(55.22)

1850

(52.38)

3

(76.2)

3.068

(77.927)

11000

(311.48)

7700

(218.03)

6250

(176.98)

5300

(150.07)

4750

(134.50)

4300

(121.76)

3900

(110.43)

3700

(104.77)

3450

(97.69)

3250

(92.03)

4

(101.6)

4.026

(102.260)

23000

(651.27)

15800

(447.39)

12800

(362.44)

10900

(308.64)

9700

(274.67)

8800

(249.18)

8100

(229.36)

7500

(212.37)

7200

(203.88)

6700

(189.72)

NOTE - Capacity given in cubic feet (

m

3

) of gas per hour and based on 0.60 specific gravity gas.

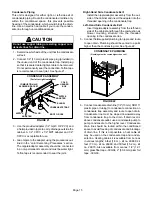

Electrical

A field make-up box is provided for line voltage wiring.

Line voltage wiring to unit is done through the J69 jack

from the field make-up box to plug P69 from the control

box. See figures 25 and 26 for make-up box installation.

Refer to figure 27 for schematic wiring diagram and trouĆ

bleshooting, figure 28 for point-to-point field wiring and

figure 29 for a detailed illustration of the Surelight inteĆ

grated control.

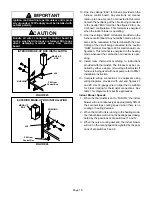

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

CAUTION

Electrostatic discharge can affect electronic comĆ

ponents. Take precautions during furnace installaĆ

tion and service to protect the furnace's electronic

controls. Precautions will help to avoid control exĆ

posure to electrostatic discharge by putting the

furnace, the control and the technician at the same

electrostatic potential. Neutralize electrostatic

charge by touching hand and all tools on an unĆ

painted unit surface, such as the gas valve or blowĆ

er deck, before performing any service procedure.

1 - Select circuit protection and wire size according to

the unit nameplate. The power supply wiring must

meet Class 1 restrictions.

2 - A snaphole bushing is provided to seal around the

wiring as it enters the cabinet. A snaphole plug is proĆ

vided to seal the unused wire entry hole.

3 - Install a separate disconnect switch (protected by eiĆ

ther a fuse or circuit breaker) near the unit so that

power can be turned off for servicing.

4 - Install field makeĆup box on either side, inside or out

of the cabinet. Knockouts are provided in box and

cabinet to facilitate wiring. See figures 25 and 26.

To ensure proper grounding of the furnace, two lockĆ

washers are included in the electrical make-up box

bag assembly. Place each lockwasher on a securing

screw before installing the make-up box. Make sure

the lockwasher breaks the paint on the cabinet so

that the washer is touching metal. Unit is not properly

grounded if paint has not been removed by the lockĆ

washer.

5 - Remove cap from knockout in blower deck on the

same side as the installed make-up box.

6 - Insert the three-pin (P69) plug from the control box

into the knockout provided in the blower deck.

7 - Connect jack (J69) from make-up box to jack plug in

blower deck.

8 - Before connecting the thermostat or the power wirĆ

ing, check to make sure the wires will be long enough

for servicing at a later date. Remove the blower acĆ

cess panel to check the length of the wire.

9 - Electrically ground unit in accordance with local

codes or, in the absence of local codes, according to

the current National Electric Code (ANSI/NFPA No.

70) and in Canada with the current Canadian Electric

Code part 1 (CSA standard C22.1). The ground wire

is provided in the field make-up box.