Page 32

High Altitude Information

Refer to table 17 for manifold pressure settings for instalĆ

lations at altitudes from 0 to 7500 feet (0 to 2286 m).

NOTE - In Canada, certification for installations at elevaĆ

tions over 4500 feet (1372 m) is the jurisdiction of local auĆ

thorities.

The pressure switch(es) are factory-set and should not

be adjusted. The -75 is equipped with both a high- and

low-heat pressure switch. The -100 and -125 units have a

single pressure switch.

Other Unit Adjustments

NOTE - Disconnect power to unit before making any

adjustments.

Heat Anticipation Settings

Thermostat anticipator setting (if adjustable) should be

set according to amps listed on wiring diagram on unit.

Flame Rollout Switch

Factory set: No adjustment necessary.

Limit Control

Factory set: No adjustment necessary.

Pressure Switches

Factory set: No adjustment is necessary.

Temperature Rise

Check temperature rise and, if necessary, adjust blower

speed to maintain temperature rise within range shown

on unit rating plate.

Electrical

1 - Check all wiring for loose connections.

2 - Check circuit breaker located on unit control box.

3 - Check for the correct voltage at the furnace (furnace

operating).

4 - Check amp-draw on the blower motor.

Motor Nameplate __________Actual__________.

NOTE - Do not secure electrical conduit directly to ductĆ

ing or structure.

Electronic Ignition

The SureLight integrated control has an internal watchĆ

guard feature. The feature serves as an automatic reset

device for ignition controls locked out because the burner

has failed to light. After one hour of continuous thermostat

demand for heat, the watchguard will break and remake

thermostat demand to the furnace and automatically reĆ

set the control to relight the furnace.

Burner Flame

Start burner and allow to operate for a few minutes to esĆ

tablish normal burning conditions. Check burner flame by

observation. Flame should be predominantly blue and

strong in appearance.

Check burner flame periodically to ensure proper opera-

tion.

Service

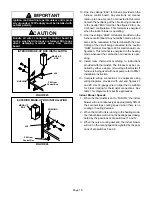

WARNING

Disconnect power before servicing unit.

CAUTION

Label all wires prior to disconnection when servicĆ

ing controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after

servicing.

Annual Service

At the beginning of each heating season, system should

be checked as follows by a qualified service technician:

Electrical

1 - Check all wiring for loose connections.

2 - Check circuit breaker located on unit control box.

3 - Check for the correct voltage at the furnace (furnace

operating).

4 - Check amp-draw on the blower motor.

Motor Nameplate_________Actual_________

5 - Check to see that heat (if applicable) is operating.

Blower

Check the blower wheels for debris and clean if necesĆ

sary. The blower motors are prelubricated for extended

bearing life. No further lubrication is needed.

Filters

1 - Filters must be cleaned or replaced when dirty to as-

sure proper furnace operation.

2 - Reusable foam filters used with the unit can be

washed with water and mild detergent.

3 - If replacement is necessary, order Lennox part no.

31J81 for 14 inches x 25 inches (356 x 635 mm) filĆ

ter for G32V-75 units and P-8-7831 for 20 inches x

25 inches (508 x 635 mm) filter for G32V-100 and

-125 units.

Intake and Exhaust Lines

Check intake and exhaust lines and all connections for

tightness and make sure there is no blockage. Also check

condensate line for free flow during operation.

Insulation

Outdoor piping insulation should be inspected yearly for

deterioration. If necessary, replace with same materials.

Winterizing and Condensate Trap Care

1 - Turn off power to unit.

2 - Have a shallow pan ready to empty condensate waĆ

ter. Avoid spilling water into the control box.

3 - Remove clamp from flue assembly and remove boot

or cap. Empty water from cap. Visually inspect botĆ

tom of flue assembly. Replace boot and clamp.

4 - Remove boot from condensate trap and empty waĆ

ter. Inspect trap then replace boot.