Page 7

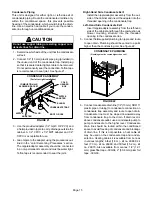

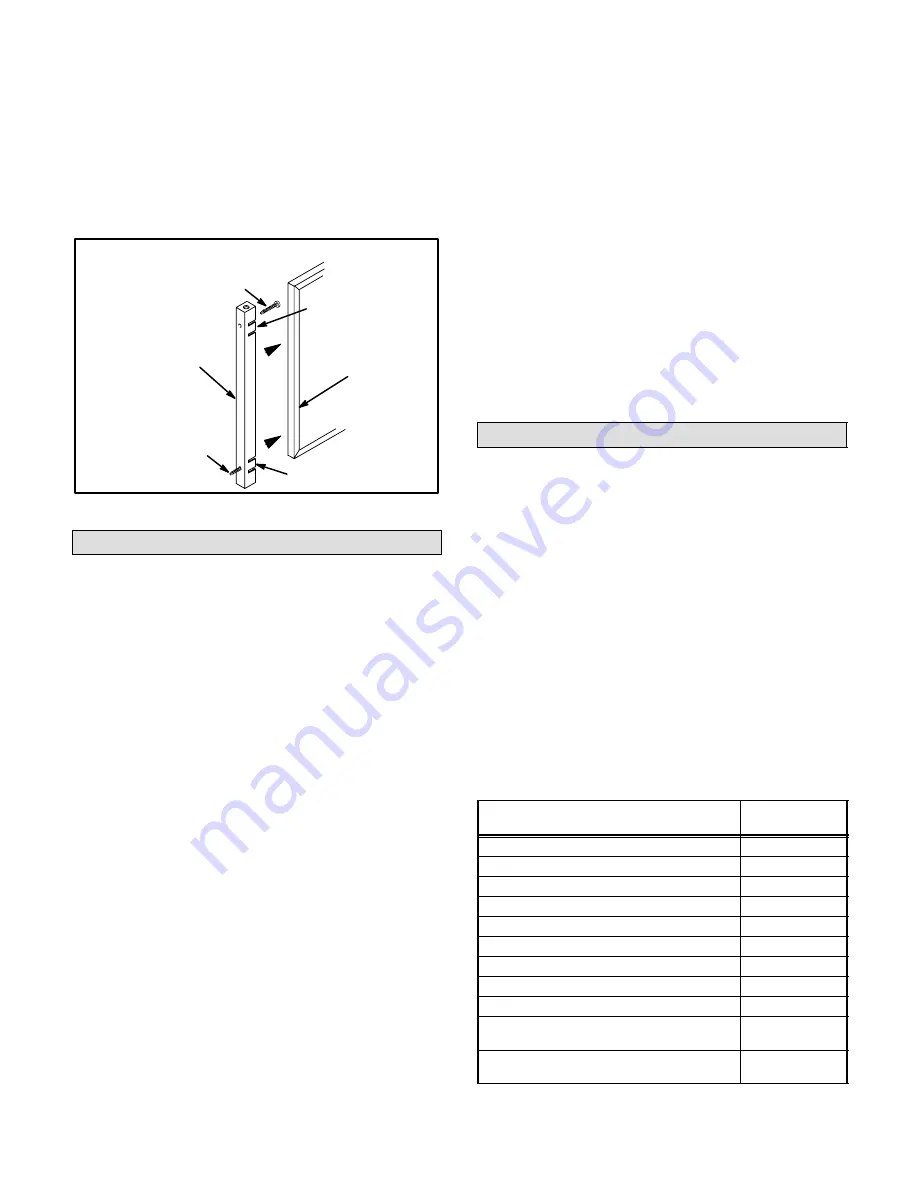

4 - Position filter door on end of filter so that the thumb

tab side of the filter door is away from the furnace.

Squeeze thumb tabs to secure filter to door.

5 - Guide filter and filter door into the filter rack installed

on side of furnace. Push door into filter rack until se-

cure.

6 - To remove filter, pull filter door pins until door is re-

leased from filter rack.

FIGURE 6

FILTER DOOR ASSEMBLY

FILTER DOOR

PIN

FILTER DOOR

FILTER

FILTER DOOR

PIN

TAB

TAB

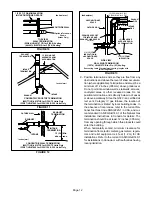

Duct System

Use industry-approved standards to size and install the

supply and return air duct system. This will result in a quiet

and low-static system that has uniform air distribution. If

the G32V unit is being installed as a replacement for an

existing furnace, the existing supply and return air duct

system should be evaluated to make sure that it is approĆ

priately sized.

The total external static pressure (ESP) should not exĆ

ceed 0.8" w.c. The ESP calculation should include presĆ

sure losses caused by electronic air cleaners, filters,

cooling coils, the duct system, registers and grilles. A

properly sized duct system will help to optimize efficiency

and reliability and to minimize sound levels. Operation of

a G32V unit outside of its specified static pressure range

will result in poor performance and will reduce the useful

life-expectancy of the product and its components.

Supply Air Plenum

Furnaces installed without a cooling coil require the installaĆ

tion of a removable access panel in the supply air duct. The

access panel should be large enough to permit inspection

(either by smoke or reflected light) of the heat exchanger for

leaks after installation. The furnace access panel must alĆ

ways be in place when the furnace is operating and it must

not allow leaks into the supply air duct system.

Return Air Plenum

See dimension illustration for proper return air duct size.

NOTE - For bottom return air, return air duct should be seĆ

cured to the unit using rivets or S-locks. For side return

air, secure return air duct to filter rack using screws. When

using screws, take care to avoid interference with the filĆ

ter which may cause improper filtration.

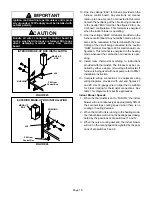

The return air must not be drawn from a room where

another gas appliance (ie., a water heater) is

installed.

Even though this furnace draws its combusĆ

tion air from outside of the structure, other gas apĆ

pliances that share a utility room may not. When return

air is drawn from a room, a negative pressure is created

in the room. If a gas appliance is operating in a room

with negative pressure, the flue products can be pulled

back down the vent pipe and into the room. This reverse

flow of the flue gas may result in incomplete combustion

and the formation of carbon monoxide gas. This toxic

gas might then be distributed through the house by the

furnace duct system.

Pipe & Fittings Specifications

All pipe, fittings, primer and solvent cement must conform

with American National Standard Institute and the AmeriĆ

can Society for Testing and Materials (ANSI/ASTM) stanĆ

dards. The solvent shall be free flowing and contain no

lumps, undissolved particles or any foreign matter that

adversely affects the joint strength or chemical resistance

of the cement. The cement shall show no gelation, stratifiĆ

cation, or separation that cannot be removed by stirring.

Refer to table 3 for approved piping and fitting materials.

Primers and solvents must meet ASTM specifications.

PVC primer is specified in ASTM F 656. Use PVC solvent

cement as specified in ASTM D 2564 and ABS solvent

cement as specified in ASTM D 2235. Low temperature

solvent cement is recommended. Metal or plastic strapĆ

ping may be used for vent pipe hangers.

Table 4 lists the available exhaust termination kits. All

Lennox vent terminations are PVC.

TABLE 3

PIPING AND FITTINGS SPECIFICATIONS

PIPE & FITTING MATERIAL

ASTM

SPECIFICATION

Schedule 40 PVC (Pipe)

D1785

Schedule 40 PVC (Cellular Core Pipe)

F891

Schedule 40 PVC (Fittings)

D2466

Schedule 40 CPVC (Pipe)

F441

Schedule 40 CPVC (Fittings)

F438

SDR-21 PVC (Pipe) or SDR-26 PVC (Pipe)

D2241

SDR-21 CPVC (Pipe) or SDR-26 CPVC (Pipe)

F442

Schedule 40 ABS (Pipe)

D1527

Schedule 40 ABS (Fittings)

D2468

ABS-DWV (Drain Waste & Vent)

(Pipe & Fittings)

D2661

PVC-DWV (Drain Waste & Vent -

Pipe & Fittings)

D2665