Page 18

Testing for Proper Venting and Sufficient Combustion Air

WARNING

CARBON MONOXIDE POISONING HAZARD!

Failure to follow the steps outlined below for each

appliance connected to the venting system being

placed into operation could result in carbon monox

ide poisoning or death.

The following steps shall be followed for each ap

pliance connected to the venting system being

placed into operation, while all other appliances con

nected to the venting system are not in operation.

After the G41UF vent system has been completed, the fol

lowing test should be conducted to ensure proper venting

and sufficient combustion air has been provided to the

G41UF, as well as to other gasfired appliances which are

separately vented. The test should be conducted while all

appliances (both in operation and those not in operation)

are connected to the venting system being tested. If the

venting system has been installed improperly, or if provi

sions have not been made for sufficient amounts of com

bustion air, corrections must be made as outlined in the

previous section.

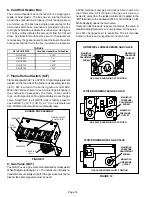

1 − Seal any unused openings in the venting system.

2 − Visually inspect the venting system for proper size and

horizontal pitch. Determine there is no blockage or re

striction, leakage, corrosion, or other deficiencies

which could cause an unsafe condition.

3 − To the extent that it is practical, close all building doors

and windows and all doors between the space in which

the appliances connected to the venting system are lo

cated and other spaces of the building.

4 − Close fireplace dampers.

5 − Turn on clothes dryers and any appliances not con

nected to the venting system. Turn on any exhaust

fans, such as range hoods and bathroom exhausts, so

they will operate at maximum speed. Do not operate a

summer exhaust fan.

6 − Follow the lighting instruction to place the G41UF or

other appliance being inspected into operation. Adjust

thermostat so appliance will operate continuously.

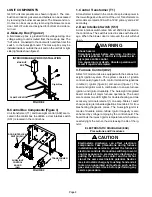

7 − Test for spillage of flue gases at the draft hood relief

opening after 5 minutes of main burner operation. Use

the flame of match or candle, or smoke from a ciga

rette, cigar.

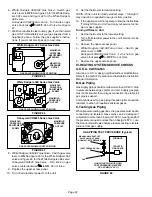

8 − If improper venting is observed during any of the

above tests, the venting system must be corrected or

sufficient combustion/makeup air must be provided.

The venting system should be resized to approach

the minimum size as determined by using the ap

propriate tables in appendix G in the current standards

of the National Fuel Gas Code ANSI−Z223.1/NPFA 54

in the U.S.A., and the appropriate Natural Gas and

Propane appliances venting sizing tables in the cur

rent standard of the CSA−B149.1 Natural Gas and

Propane Installation Code in Canada.

9 − After determining that each appliance remaining

connected to the common venting system properly

vents when tested as indicated in step 3, return

doors, windows, exhaust fans, fireplace dampers

and any other gasburning appliance to their previous

condition of use.

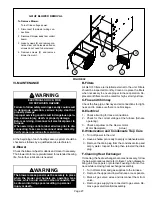

General Guidelines for Vent Terminations for NonDirect

Vent Installations.

In NonDirect Vent installations combustion air is taken

from indoors and the flue gases are discharged to the out

doors. The G41UF is then classified as a nondirect vent,

Category IV gas furnace. In NonDirect Vent installations

the vent termination is limited by local building codes. In

the absence of local codes, refer to the current National

Fuel Gas Code ANSI Z223−1/NFPA 54 in U.S.A., and cur

rent standards CSA−B149.1 of the Natural Gas and Pro

pane Installation Codes in Canada for details.

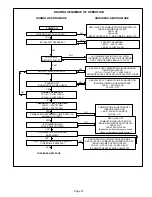

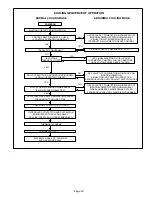

Position termination ends according to locations given in

figure 19. In addition, position termination ends so they are

free from any obstructions and above the level of snow ac

cumulation (where applicable). The termination should be

at least 12 inches (305mm) from any opening through

which flue products could enter the building.

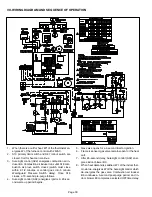

At vent termination, care must be taken to maintain

protective coatings over building materials (prolonged

exposure to exhaust condensate can destroy protective

coatings). It is recommended that the exhaust outlet not be

located within 6 feet (1.8m) of a condensing unit because

the condensate can damage the painted coating.

NOTE − If winter design temperature is below 32°F (0°C),

exhaust piping should be insulated with 1/2" (13mm), Ar

maflex or equivalent when run through unheated space.

Do not leave any surface area of exhaust pipe open to out

side air; exterior exhaust pipe should be insulated with 1/2"

(13mm) Armaflex or equivalent. In extreme cold climate

areas, 3/4" (19mm) Armaflex or equivalent may be neces

sary. Insulation on outside runs of exhaust pipe must be

painted or wrapped to protect insulation from deterioration.

Exhaust pipe insulation may not be necessary in some

specific applications.

NOTE − During extremely cold temperatures, below

approximately 20°F (6.7°C), units with long runs of vent

pipe through unconditioned space, even when insulated,

may form ice in the exhaust termination that prevents the

unit from operating properly. Longer run times of at least 5

minutes will alleviate most icing problems. Also, a heating

cable may be installed on exhaust piping and termination to

prevent freeze−ups. Heating cable installation kit is avail

able from Lennox. See Condensate Piping section for part

numbers.