Page 10

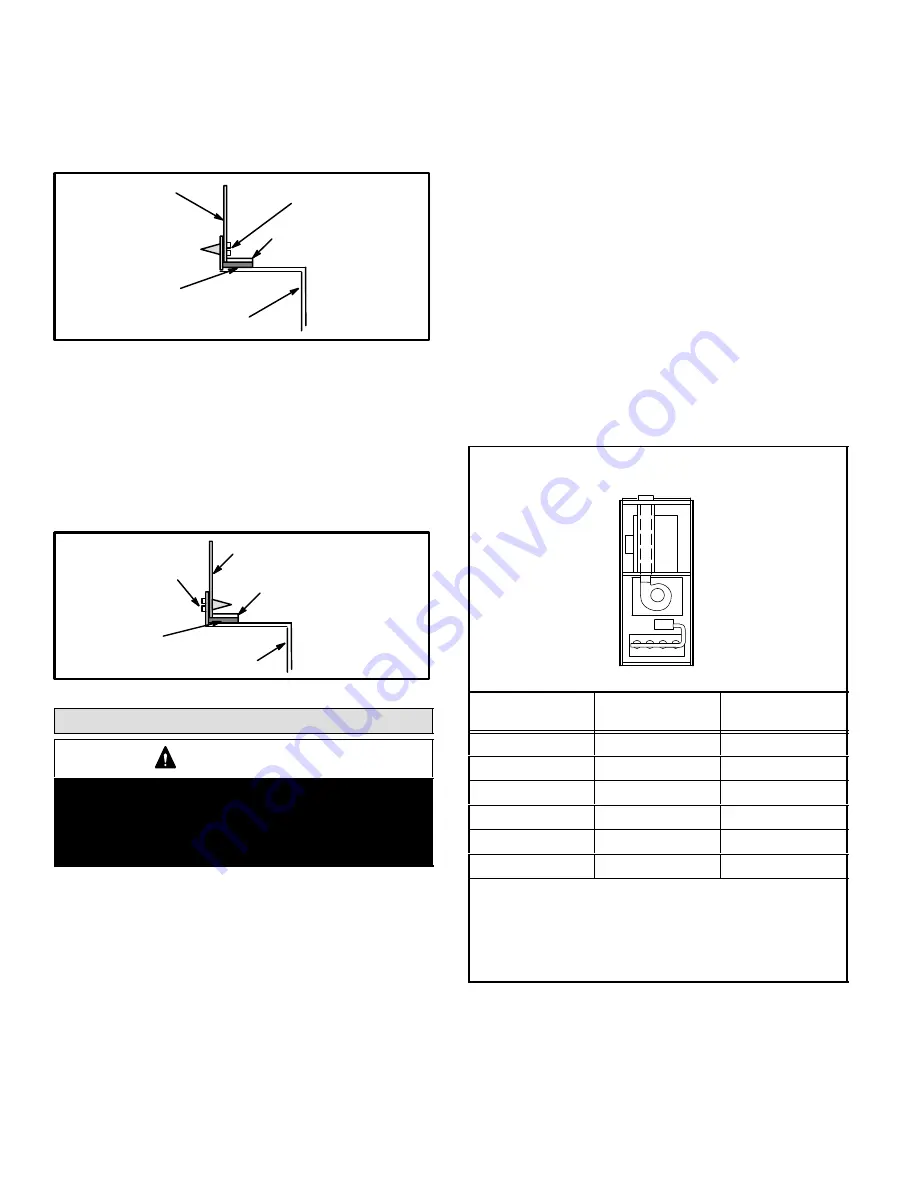

Return Air Opening −− Downflow Units

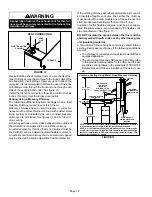

The following steps should be taken when installing ple-

num:

1 − Bottom edge of plenum should be flanged with a

hemmed edge (See figure 7).

SECURE FROM

OUTSIDE CABINET

HEMMED EDGE

PLENUM

FIBERGLASS SEALING

STRIP

(Field Provided)

CABINET SIDE PANEL

Side View

FIGURE 7

2 − Fiberglass sealing strips should be used.

3 − In all cases, plenum should be secured to top flanges

of furnace with sheet metal screws.

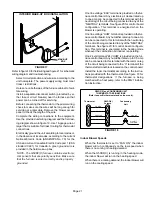

4 − In closet installations, it may be impossible to install

sheet metal screws from the outside. In this case,

make plenum with a removable front and install

screws from the inside (See figure 8).

5 − Make certain that an adequate seal is made.

SECURE FROM

INSIDE CABINET

HEMMED EDGE

FIBERGLASS

SEALING STRIP

(Field Provided)

CABINET SIDE

PANEL

PLENUM

Side View

FIGURE 8

Setting Equipment

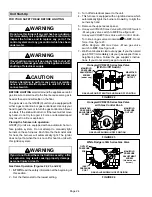

WARNING

Do not install the furnace on its front or its back. Do

not connect the return air ducts to the back of the fur-

nace. Doing so will adversely affect the operation of

the safety control devices, which could result in per-

sonal injury or death.

Install the G50DF(X) gas furnace as shipped.

Do not

install the furnace horizontally.

Select a location that allows for the required clearances

that are listed on the unit nameplate. Also consider gas

supply connections, electrical supply, vent connection,

and installation and service clearances [24 inches (610

mm) at unit front].

The unit must be level.

NOTE − 1/3 hp blower motors are equipped with four flex-

ible mounting legs, and 1/2 hp blower motors are equipped

with three flexible legs and one rigid leg. The rigid leg is

equipped with a shipping bolt and a flat white plastic wash-

er (rather than the rubber mounting grommet used with a

flexible mounting leg).

The bolt and washer must be re-

moved before the furnace is placed into operation.

Af-

ter the bolt and washer have been removed, the rigid leg

will not touch the blower housing.

NOTE − G50DF−36C−110 units include a bracket which sta-

bilizes the blower motor during shipping. The bracket is se-

cured to the blower housing by two screws.

This bracket

must be removed prior to placing the unit into opera-

tion.

See figure 1.

Downflow Application

Allow for clearances to combustible materials as indi-

cated on the unit nameplate. Minimum clearances for

closet or alcove installations are shown in figure 9.

Downflow Application Installation Clearances

Top

Bottom

Left Side

Right Side

Type of Vent

Connector

Type C

Type B1

Top

1 in. (25 mm)

1 in. (25 mm)

*Front

3 in. (76 mm)

3 in. (76 mm)

Back

0

0

Sides

0

†

0

Vent

6 in. (152 mm)

1 in. (25 mm)

Floor

NC††

NC††

*Front clearance in alcove installation must be 24 in. (610 mm).

Maintain a minimum of 24 in. (610 mm) for front service access.

†Left side requires 3 in. if a single wall vent is used on 14 −1/2 in. cab-

inets, or 2 in. if a single wall vent is used on 17 − 1/2 in. cabinets.

††The furnace may be installed on a combustible wood floor if an

optional additive base is installed between the furnace and the

combustible floor.

FIGURE 9