Page 18

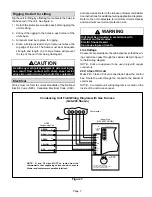

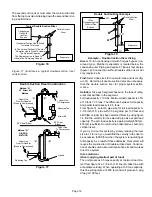

Liquid And Suction Line Service Valve

(Valve Open)

Schrader

valve

service

port

service port

cap

insert hex

wrench here

to indoor coil

to outdoor coil

stem cap

Schrader valve open

to line set when valve is closed

(front seated)

service

port

service

port cap

stem cap

insert hex

wrench here

Liquid And Suction Line Service Valve

(Valve Closed)

(valve front seated)

to outdoor coil

to indoor coil

Figure 19

Opening the Liquid Line Service Valve:

1 − Remove stem cap with an adjustable wrench.

2 − Use a service wrench with a hex−head extension to

back the stem out counterclockwise as far as it will go.

3 − Replace the stem cap. Tighten finger tight, then tighten

an additional 1/6 turn.

WARNING

Do not attempt to backseat this valve. Attempts to

backseat this valve will cause the snap ring to ex

plode from valve body under pressure of refrigerant.

Personal injury and unit damage will result.

Closing the Liquid Line Service Valve:

1 − Remove stem cap with an adjustable service wrench.

2 − Using a service wrench with a hex−head extension, turn

the stem clockwise to seat the valve. Tighten firmly.

3 − Replace the stem cap. Tighten finger tight, then tighten

an additional 1/6 turn.

All units are equipped with a full service ball valve, as

shown in figure 20. One service port that contains a

Schrader valve core is present in this valve. A cap is also

provided to seal off the service port. The valve is not re

buildable so it must always be replaced if failure has oc

curred.

Opening the Suction Line Service Valve: 090 and 120

1 − Remove the stem cap with an adjustable wrench.

2 − Using a service wrench, turn the stem counterclock

wise for 1/4 of a turn.

3 − Replace the stem cap and tighten it firmly.

Closing the Suction Line Service Valve: 090 and 120

1 − Remove the stem cap with an adjustable wrench.

2 − Using a service wrench, turn the stem clockwise for 1/4

of a turn.

3 − Replace the stem cap and tighten firmly.

Suction Line (Ball Type) Service Valve

(Valve Open)

Schrader Valve

Service Port

Stem Cap

Stem

Use Adjustable Wrench

Rotate Stem Clockwise 90° To Close

Rotate Stem Counterclockwise 90° To Open

Ball

(Shown Open)

To Outdoor Coil

To Indoor Coil

Service Port Cap

Figure 20

Leak Testing

After you have connected the line set to the indoor and out

door units, check the line set connections and indoor unit

for leaks.

WARNING

Never use oxygen to pressurize refrigeration or air

conditioning system. Oxygen will explode on con

tact with oil and could cause personal injury. When

using a high pressure gas such as nitrogen or CO2

for this purpose, be sure to use a regulator that can

control the pressure down to range of 1 to 2 psig (6.9

to 13.8 kPa).

Using an Electronic Leak Detector or Halide

1 − With both manifold valves closed, open the valve on

the HCFC22 cylinder (vapor only).