Page 23

Evaporator Coil

1 − If necessary, clean the coil.

2 − Check connecting lines and coils for evidence of oil

leaks.

3 − If necessary, check the condensate line and clean it.

Indoor Unit

1 − Clean or change filters.

2 − Adjust the blower speed for cooling. Measure the pres

sure drop over the coil to determine the correct blower

CFM. Refer to the unit information service manual for

pressure drop tables and procedure.

3 − On belt drive blowers, check the belt for wear and prop

er tension.

4 − Check all wiring for loose connections.

5 − Check for correct voltage at the unit (blower operat

ing).

6 − Check amp−draw on blower motor.

Unit nameplate_________ Actual ____________.

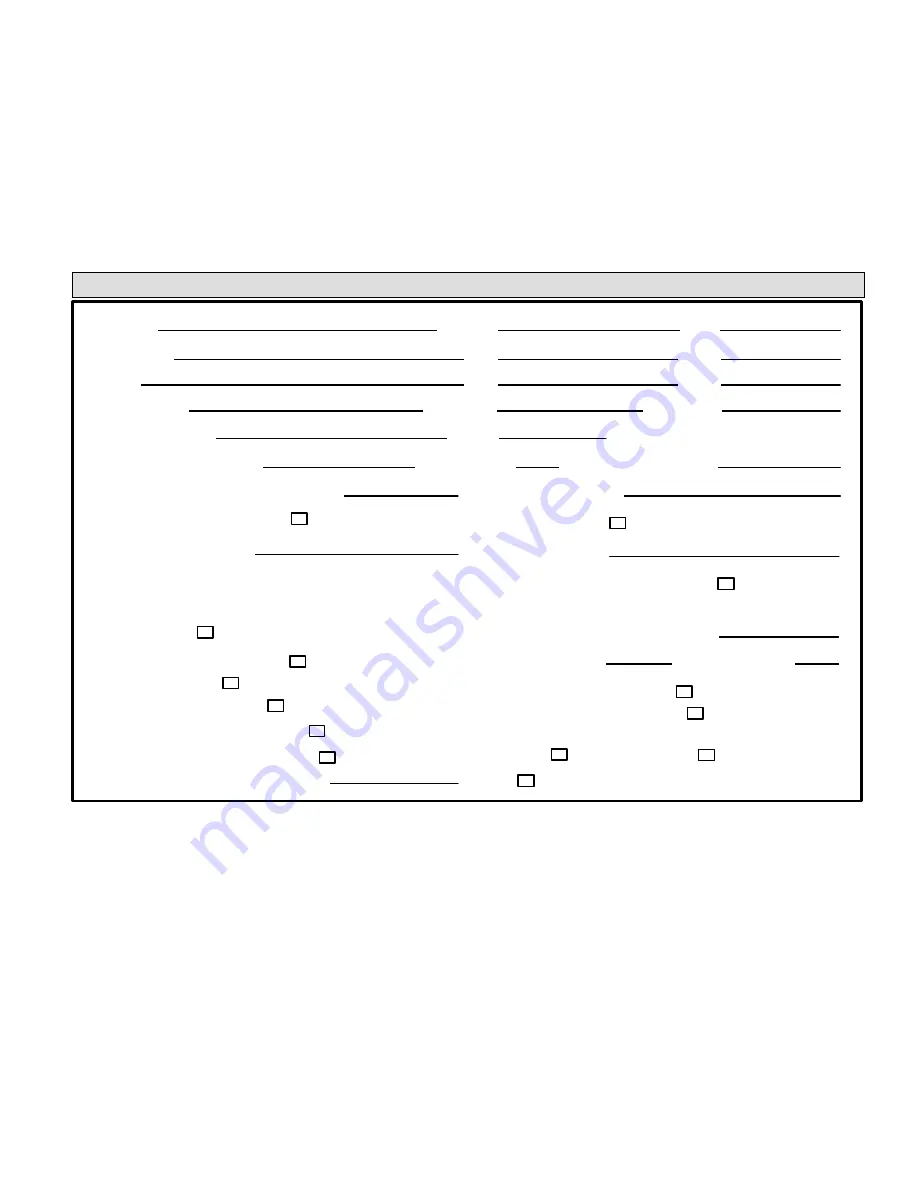

Start−Up & Performance Check List: HS29−072, 090, & 120

Job Name

Job Location

Installer

Unit Model No.

Nameplate Voltage

Minimum Circuit Ampacity

Maximum Overcurrent Protection Size

Refrigerant Lines:

Service Valves Fully Opened?

Condenser Fan Checked?

Job No.

City

City

Serial No.

Date

State

State

Technician

Amps:

Supply Amps:

Condenser Fan Amps:

Compressor Amps:

Indoor Filter Clean?

Indoor Blower RPM

Electrical Connections Tight?

Supply Voltage (Unit Off)

S.P. Drop Over Evaporator (Dry)

Condenser Entering Air Temperature

Discharge Pressure

Suction Pressure

COOLING SECTION

THERMOSTAT

Refrigerant Charge Checked?

Calibrated?

Properly Set?

Level?

Properly Insulated?

Suction Service Valve Caps Tight?

Voltage With Compressor Operating

Leak Checked?

Liquid Service Valve Caps Tight?

Blower interlocked with compressor?

Compressor Rotation Checked?