• 16 •

3 cm/m

+

+

+

+

+

ǻS

OU

T

OU

T

IN

IN

Installation, operation and maintenance /

INALTO-IOM-1809-E

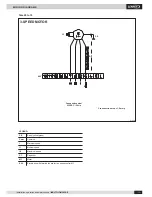

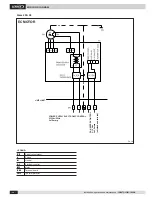

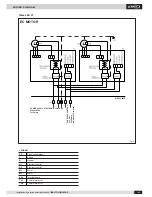

ELECTRICAL CONNECTIONS

CONNECTIONS TO THE TERMINAL BOARD

RECOMMENDATIONS!

Before carrying out electrical connections, ensure that the electricity supply

to the supply line has been cut off, checking that the on-off switch is in the

OFF position.

- Only quali

fi

ed electricians should carry out the electrical connections.

- Check that the mains supply is single-phase 230 Vac/1/50 Hz (± 10%).

- Operating the unit with voltages outside the above limits could cause

malfunction and renders the warranty null and void.

- The power supply line should be

fi

tted with at least a switch isolator in

conformity with European standard EN60947-3.

- Make sure that the electrical system is suitable for providing not only the

working current required by the unit, but also the necessary current for

powering household and other electrical appliances already in use. Any

electrical and mechanical alterations or tampering render the warranty

null and void.

The cables should be suf

fi

ciently long so that they are not permanently taut

or create throttling or compression on metal parts.

The power cables should be suf

fi

ciently long so that in the event of acci-

dental tugging the active wires are subjected to stress before the earth wire.

Connect the earth wire to the relative terminal marked with the symbol .

Comply with the safety regulations in force in the country of installation.

The electrical connections should be made to the terminal boards on the

side of the appliance. Each terminal is identi

fi

ed by the label to be found on

the terminal boards.

CAUTION !

FAILURE TO COMPLY WITH THE INDICATED CONNECTIONS MAY

CAUSE MOTOR BURNOUT!

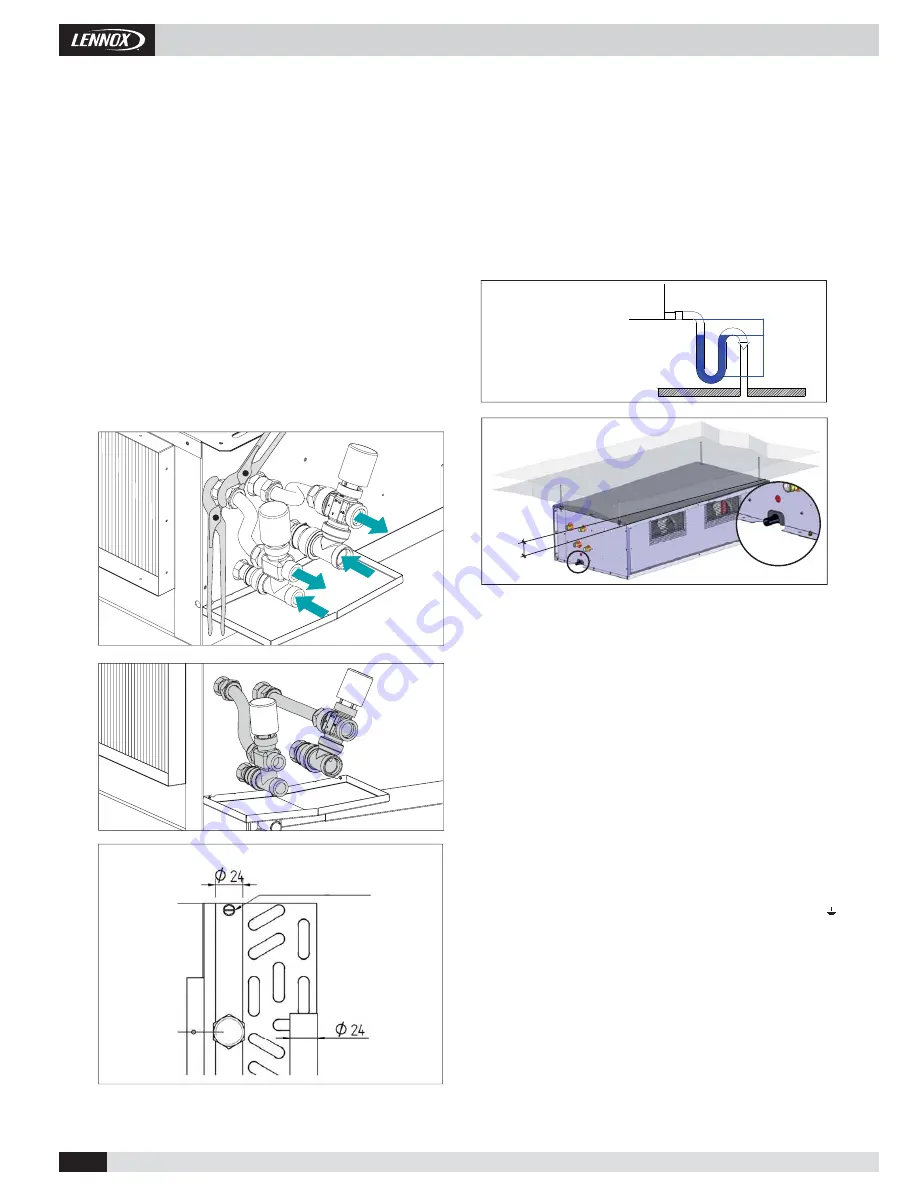

CONDENSATE WATER DRAINAGE

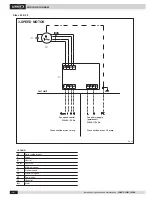

The condensate drain pipe should slope downwards by at least 3 cm/m

and should not have ascending or throttled sections in order to ensure a

regular

fl

ow of water. It is advisable for a trap to be

fi

tted. The condensate

drain pipe should be connected to a rainwater drainage system. Do not

use sewage systems to avoid possible rising of odours in the event of

evaporation of the water in the trap. Upon completion of work, check

that the condensate

fl

ows out properly by pouring water into the tray. The

condensate water drainage system should be fabricated in a workmanlike

manner and should be periodically checked.

The manufacturer cannot be held liable for any damage caused by drip-

ping in the absence of a valve or of periodic maintenance of the drainage

system.

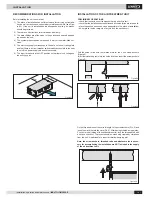

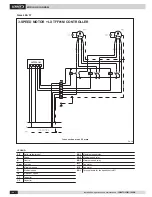

Pic. 25

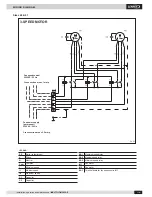

Pic. 26

TRAP (PLUMBING)

H1=

∆

p/10

H2=((

∆

p/10)/2 + 30

∆

p=

in Pa

H1; H2 = mm

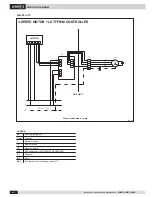

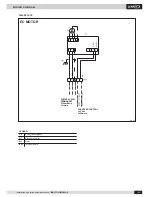

Pic. 27

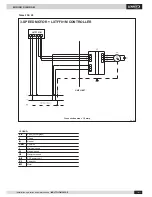

Pic. 28

HYDRAULIC CONNECTION

M6 vent

with hexagonal head pin

MAIN HYDRAULIC CONNECTION

CAUTION !

Always use a wrench and counter-wrench for connection of the coil

to the pipes (pic. 25). If the valve is installed, suitably insulate the

valve body with insulating material (pic. 26).

Connect the water inlet and outlet pipes, observing the indications given

on the side of the unit. Correctly insulate the water supply pipes to prevent

dripping during the cooling mode of operation. A shutoff valve should be

inserted on the water supply pipe and a balancing valve on the outlet pipe.

The valve body and balancing valve should also be properly insulated to

prevent dripping. It is the installer’s responsibility to insulate properly and

the manufacturer cannot be held liable for any insulation work.

NOTE: It is always advisable to install the valve. In the heating mode

of operation the valve reduces consumption because upon reaching

the set temperature the circulation of water is stopped to avoid wa-

sting energy (the fan coil would otherwise continue to heat like a

radiator, even with the motor at a standstill). In the cooling mode of

operation the valve stops the circulation of water when the set tem-

perature is reached, this stopping the internal exchanger from con-

tinuing to condense water with possible undesirable dripping onto

the fl oor. It also reduces chiller operation with consequent energy

saving.