Page 17

507232-02

9/2015

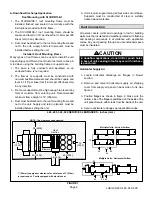

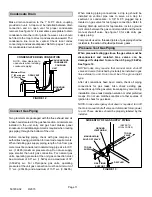

BLOWER ASSEMBLY

BLOWER

MOTOR

PULLEY

BELT TENSION

ADJUSTMENT

BOLTS

MOTOR

SUPPORT

PLATE

TO TIGHTEN BELT

Turn lower nuts on both

adjustment bolts clock

wise. Secure support

plate with upper nuts.

TO LOOSEN BELT

Turn upper nut on both ad

justment bolts counter

clockwise. Secure support

plate with lower nuts.

FIGURE 22

LOWER

ADJUSTMENT

NUT

UPPER

ADJUSTMENT

NUT

LOCKWASHER

Blower Operation and Adjustments

IMPORTANT

Three phase scroll compressors must be phased se

quentially for correct compressor and blower rota

tion. Follow “COOLING START-UP” section of instal

lation instructions to ensure proper compressor and

blower operation.

A-Blower Belt Adjustment

Maximum life and wear can be obtained from belts only if

proper pulley alignment and belt tension are maintained.

Tighten belt as shown in figure 22.

IMPORTANT

After a 24-48 hour period of operation, tighten new

belts again.

T

his will allow belt to stretch and seat

into grooves.

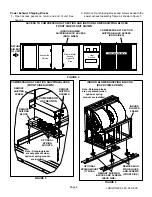

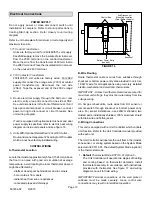

Make sure blower and motor pulley are aligned as shown in

figure 23. Also make sure motor support plate is level. See

figure 24.

FIGURE 23

PULLEY ALIGNMENT

BELT

BLOWER

PULLEY

MOTOR

PULLEY

NOT ALIGNED

ALIGNED

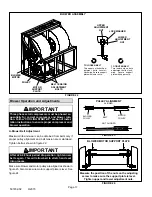

BLOWER MOTOR SUPPORT PLATE

FIGURE 24

Measure the position of the nuts on the adjusting

screw to make sure the support plate is level.

Tighten upper and lower adjustment nuts.