Page 8

LGH/LCH036, 048, 060, 072

4- From the inside of the pan, use a Vari-Bit

®

bit to

enlarge the hole to 7/8”. Do not damage coupling

threads.

5- Remove the cap over the unit bottom drain hole.

6- Slide the drain pan back into the unit.

7- From the back side of the unit, pull the drain pan

coupling through the rear condensate opening.

8- From the front side of the unit, move the drain pan

until the bottom coupling settles into the unit bottom

drain opening. Once in place, check to make sure the

coupling is still positioned through the rear

condensate drain hole.

9- Use a field-provided 3/4” plug to seal side drain

connection.

10- Replace the condensate drain mullion.

Connect Gas Piping (Gas Units)

Before connecting field-provided piping, check with gas

company or authorities having jurisdiction for local code

requirements. When installing gas supply piping, length

of run from gas meter must be considered in determining

pipe size for 0.5” w.c. (.12kPa) maximum pressure drop.

Do not use supply pipe smaller than unit gas connection.

Operating pressures at the unit gas connection must be

as shown in table 1.

TABLE 1

OPERATING PRESSURE AT GAS CONNECTION “w.c.

Natural Gas

LP / Propane Gas

Min.

Max.

Min.

Max.

036-072

4.5

10.5

11

13

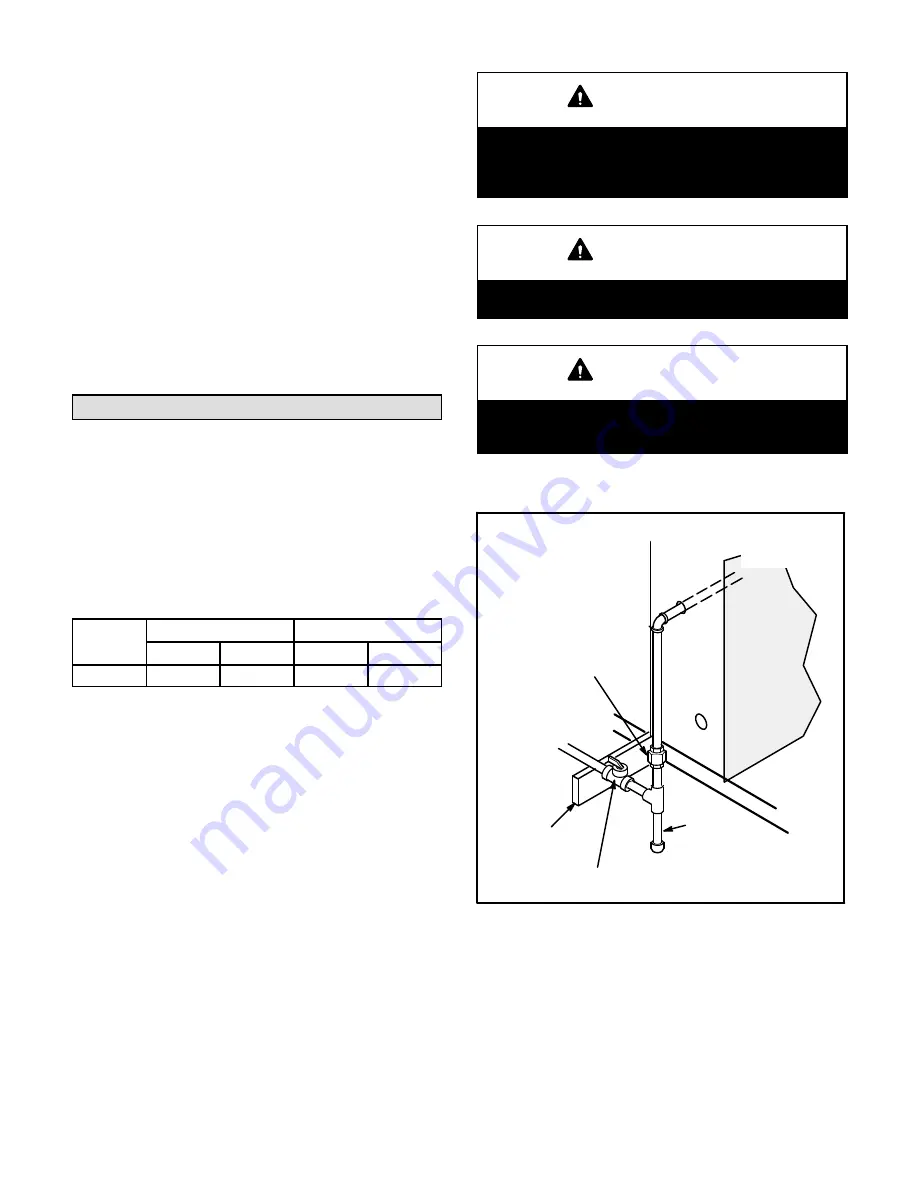

When making piping connections a drip leg should be

installed on vertical pipe runs to serve as a trap for

sediment or condensate. A 1/8” N.P.T. plugged tap is

located on gas valve for test gauge connection. Refer to

Heating Start-Up section for tap location. Install a ground

joint union between the gas control manifold and the

main manual shut-off valve. See figure 11 for gas supply

piping entering outside the unit. Figure 12 shows

complete bottom gas entry piping.

Compounds used on threaded joints of gas piping shall be

resistant to the action of liquified petroleum gases.

Do not use Teflon® tape to seal gas piping. Use a

moderate amount of pipe compound on the gas pipe only.

Make sure the two end threads are bare.

CAUTION

If a flexible gas connector is required or allowed by

the authority that has jurisdiction, black iron pipe

shall be installed at the gas valve and extend out

side the furnace cabinet.

WARNING

Do not exceed 600 in-lbs (50 ft.-lbs) torque when at

taching the gas piping to the gas valve.

IMPORTANT

Compounds used on threaded joints of gas piping

must be resistant to the actions of liquified petro

leum gases.

FIGURE 11

TO GAS

SUPPLY

MANUAL MAIN

SHUT-OFF VALVE

GAS PIPING

SUPPORT

GROUND

JOINT UNION

(REFER TO

LOCAL CODES)

DRIP LEG

OUTSIDE OF UNIT GAS PIPE CONNECTION

TO GAS

VALVE