Page 11

Gas Piping

Proper sizing of a gas piping depends on the cubic feet per

hour of gas flow required, specific gravity of the gas, and

length of run. National Fuel Gas Code Z223.1 latest edition

should be followed in all cases unless superseded by local

codes or gas company requirements. In Canada, refer to

CAN/CGA B.149.1 & .2 (latest edition).

The heating value of the gas may differ with locality. The

value should be checked with the local gas utility. For

temperature rise of unit, see unit rating plate.

Gas Piping Recommendations

• A drip leg and a ground joint union must be installed in

the gas piping. A ground joint union is recommended

by the manifold/valve.

•

When required by local codes, a manual shutoff valve

may have to be installed outside of the unit.

• Use pipe thread sealing compound resistant to

propane gas sparingly on male threads.

• The gas supply should be a separate line and installed

in accordance with all safety codes listed on Page

1. After the gas connections have been completed,

open the main shutoff valve admitting normal gas

pressure to the mains. Check all joints for leaks

with soapy solution or other material suitable for the

purpose.

Never use a flame to check for gas leaks. Explosion

causing injury or death may occur.

WARNING

•

The furnace and its field supplied manual shutoff valve

must be disconnected from the gas supply piping

system during any pressure testing of that system at

test pressures in excess of 1/2 PSIG (3.48kPa).

• A 1/8” N.P.T. plugged tapping, accessible for test

gauge connections, must be installed immediately

upstream of the gas supply connection to the furnace.

Gas Connection

The gas supply line is routed through the gas entry

location on the side of the unit (see Figure 4). A grommet is

provided in the instruction bag and should be used to seal

gas supply line to gas entry of control compartment.

Table 2. Unit Air Filter Sizes - inches

Unit Model

Filter 1

Filter 2

24, 30, 36

14 x 20 x 1

20 x 20 x 1

42, 48, 60

20 x 20 x 1

Condensate Drain

This package unit is equipped with a 3/4” FPT coupling

for condensate line connection. Plumbing must conform

to local codes. Use a sealing compound on male pipe

threads.

Do not

operate unit without a drain trap. The condensate

drain is on the negative pressure side of the blower;

therefore, air being pulled through the condensate line will

prevent positive drainage without a proper trap.

The condensate drain line must be properly trapped,

routed to a suitable drain and primed prior to unit

commissioning.

NOTE

:

Install drain lines and trap so they do not block

service access to the unit.

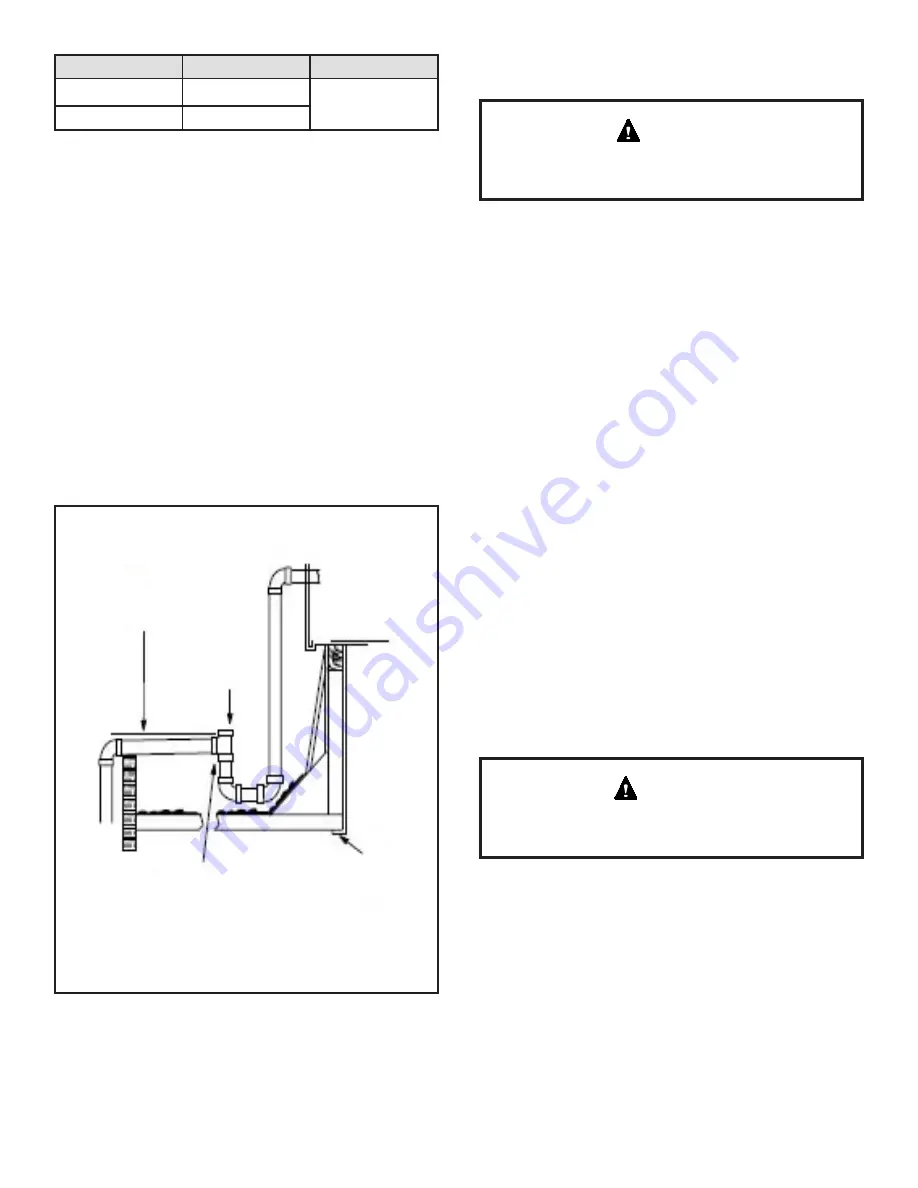

Figure 3. Typical Condensate Drain Connection

MINIMUM PITCH

1 IN (25) PER 10” (3048

MM) OF LINE

OPEN

VENT

UNIT

MOUNTING

FRAME

Trap must be deep enough to offset maximum static difference

(generally, 3 inches (76 mm) minimum). In addition, the drain line

must be supported if longer than 10 feet.

Trap must be primed at start-up.

See Figure 3 for proper drain arrangement. The drain line

must pitch to an open drain or pump to prevent clogging

of the line. Seal around the drain connection with suitable

material to prevent air leakage into the return air system.

To prime trap, pour several quarts of water into drain,

enough to fill drain trap and line.

Drain lines should be hand-tightened only. Do not use

tools to tighten fitting into drain.

CAUTION