Page 20

heater sequencers as well as the indoor blower. Upon

satisfying auxiliary heat demand, the thermostat opens

above circuits and heating elements sequence off; blower

continues to operate until all heating elements have turned

off.

Defrost System

The defrost system includes two components: the defrost

thermostat and the defrost control.

Defrost Thermostat

The defrost thermostat is located on the evaporator coil.

When the defrost thermostat senses 35°F or cooler, the

thermostat contacts close and send a signal to the defrost

control board to start the defrost timing. It also terminates

defrost when the liquid line warms up to 60°F.

Defrost Control

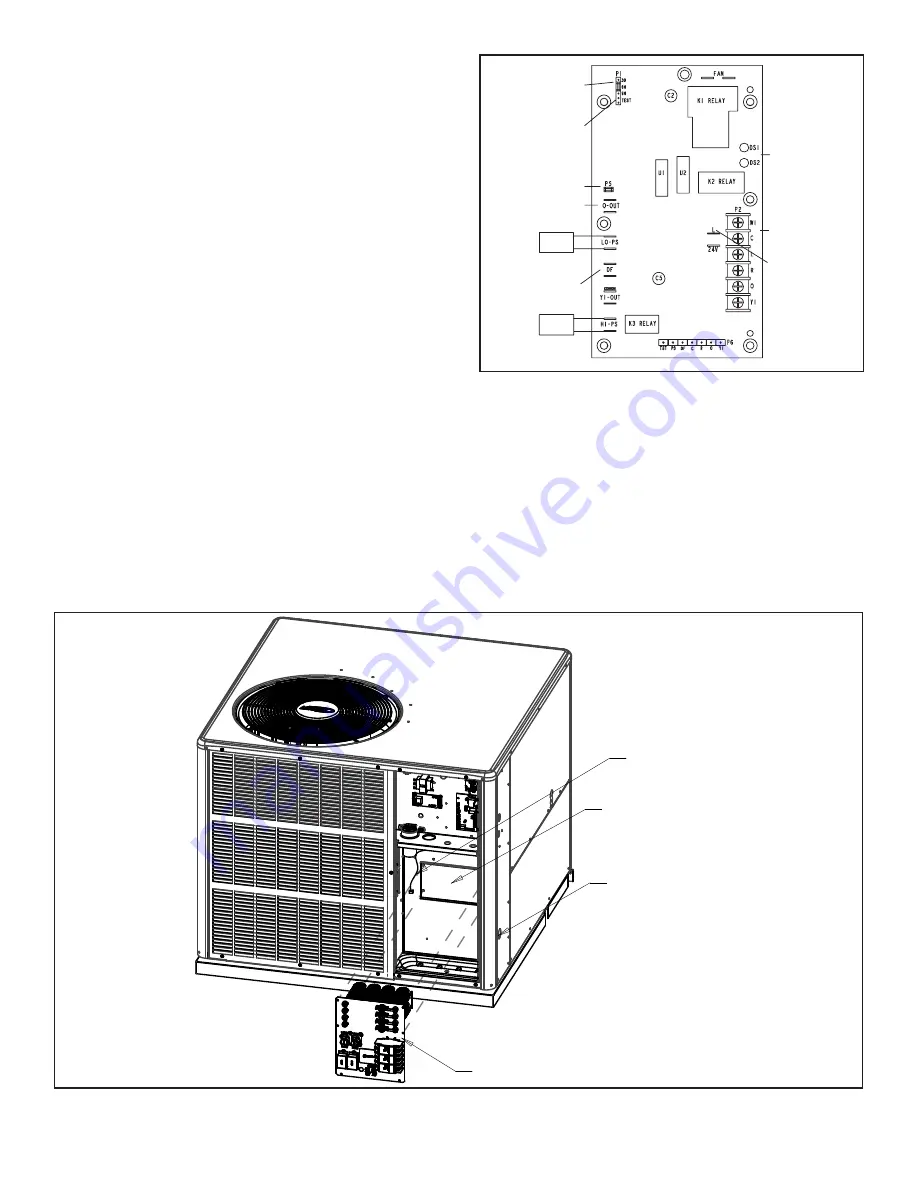

The defrost control board includes the combined functions

of time/temperature defrost control, defrost relay, diagnostic

LEDs and terminal strip for field wiring connections (see

Figure 6).

The control provides automatic switching from normal

heating operation to defrost mode and back. During the

compressor cycle (call for defrost), the control accumulates

compressor run time at 30, 60, 90 minute field-adjustable

intervals. If the defrost thermostat is closed when the

selected compressor run time interval ends, the defrost

relay is energized and the defrost begins.

Figure 10. Defrost Control Board

24V TERMINAL

STRIP

CONNECTIONS

DIAGNOSTIC

LEDS

HIGH PRESSURE

SWITCH

TEST

PINS

DEFROST TIMING

PINS (P1)

REVERSING

VALVE

DEFROST

THERMOSTAT (S6)

LOW PRESSURE

SWITCH

COMPRESSOR

DELAY PINS

S4

S87

SERVICE LIGHT

CONNECTIONS

1. An on-board outdoor ambient temperature sensor on

the defrost control bypasses the low pressure switch

during low ambient temperature below 15

°

F in heating

mode to eliminate nuisance low pressure trips.

NOTE:

15°F is an approximate temperature,

depending upon model and installation location.

2. A defrost cycle will initiate when there has been a low

pressure switch trip; the defrost sensor must be closed

and the defrost time interval must not have expired.

Figure 11. Heater Kit Accessory Installation