Page 16

Figure 8.

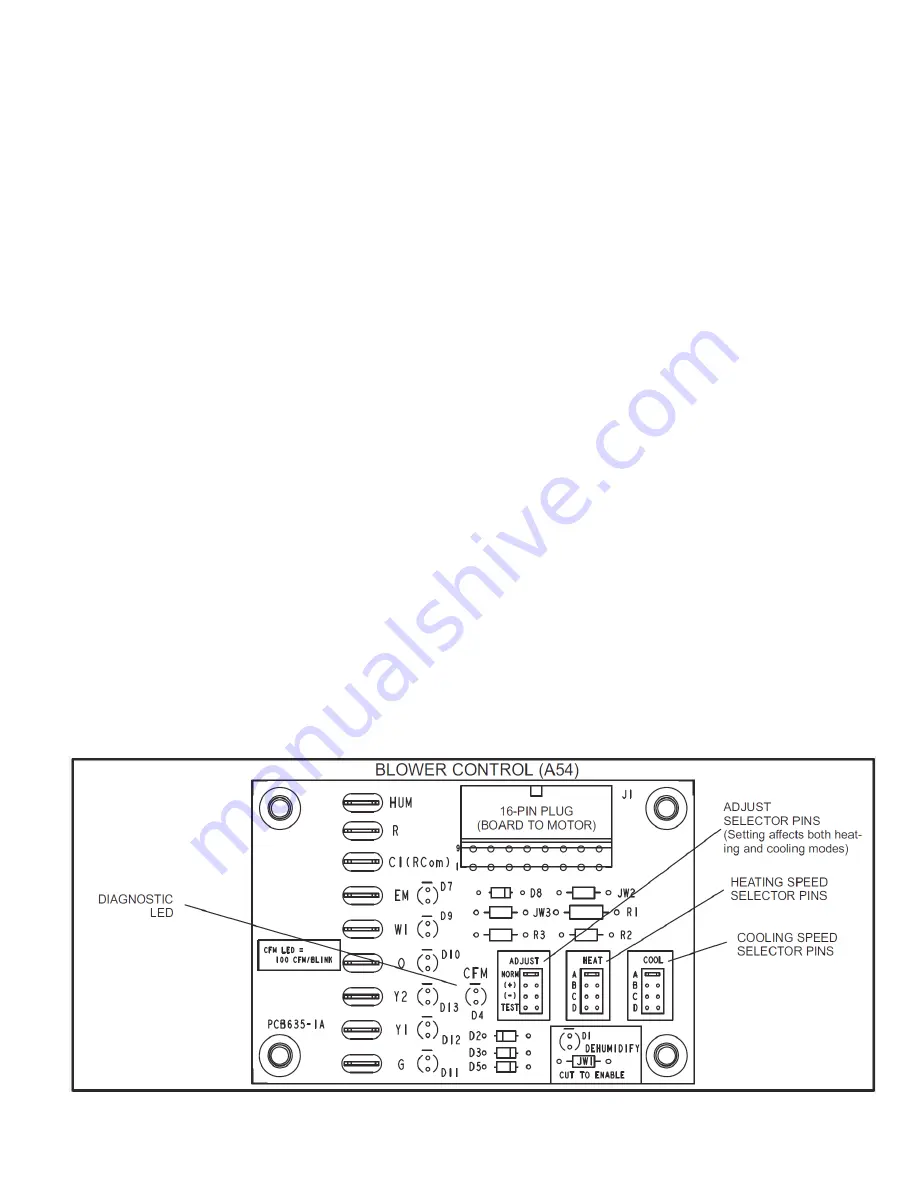

COOL

The COOL jumper is used to determine the CFM during

cooling operation. This jumper selection is activated for

cooling when Y1/Y2 is energized.

The blower motor runs at 80 percent of the selected air

flow for the first 7-1/2 minutes of each cooling demand.

This feature allows for greater humidity removal and saves

energy.

In the cooling mode, the blower control delays blower

operation for 5 seconds after the compressor starts. The

blower continues to operate for 90 seconds after the

compressor is de-energized.

HEAT

The HEAT jumper is used to determine CFM during gas

heat operation only. These jumper selections are activated

only when W1/W2 is energized.

In the heating mode, the blower control delays blower

operation for 30 seconds after the flame is established.

The blower continues to operate for 90 seconds after the

gas valve is de-energized.

CONTINUOUS FAN

When the thermostat is set for “Continuous Fan” operation

and there is no demand for heating or cooling, the blower

control will provide 50 percent of the COOL CFM selected.

DEHUMIDIFICATION

The blower control includes an HUM terminal which

provides for connection of a humidistat. The JW1 resistor

on the blower control must be cut to activate the HUM

terminal. The humidistat must be wired to open on humidity

rise. When the dehumidification circuit is used, the variable

speed motor will reduce the selected air flow rate by 25

percent when humidity levels are high. An LED (D1) lights

when the blower is operating in the dehumidification mode.

Cooling System

The cooling system is a factory-charged with HFC-R-410A.

The compressor is hermetically sealed and base-mounted

with rubber-insulated bolts.

Cooling Sequence of Operation

When the thermostat calls for cooling, R is closed to Y1

(see the wiring diagrams starting on Page 21). This

action completes the low voltage control circuit, energizing

the compressor, condenser fan motor, and blower motor.

Second stage cooling is initiated by thermostat energizing

Y2.

Unit compressors have internal protection. In the event there

is an abnormal rise in the temperature of the compressor,

the protector will open and cause the compressor to stop.

Unit is equipped with drain pan overflow protection. In the

event of a restriction/blockage to the condensate disposal

system, the overflow switch will open, breaking the “R”

signal (power) to the thermostat and canceling the call for

cool/heat.

Blower Delay – Cooling

The circulating air blower includes integrated delay timing.

Timings are not adjustable. Blower “ON” delay is 5 seconds

after the compressor starts and blower “OFF” timing is 60

seconds after the compressor shuts down.

NOTE:

There is no blower OFF delay when there is a call

for G (fan only).

Cooling System Performance

This equipment is a self-contained, factory-optimized

refrigerant system. The unit should not require adjustments

to system charge when properly installed. If unit

performance is questioned, perform the following checks.