Page 26

11 -

To clean the combustion air inducer visually inspect

and using a wire brush clean where necessary. Use

compressed air to clean off debris and any rust.

12 - Reinstall heat exchanger in vestibule. (Replace the

five screws in the cabinet from step 10 if removed).

13 - Reinstall collector box, combustion air assembly,

internal flue pipe and flue chase. Seal with high

temperature RTV. Reinstall all screws to the collector

box and combustion air inducer. Failure to replace

all screws may cause leaks. Inspect gaskets for any

damage and replace if necessary.

14 - Reinstall burner box, manifold assembly and burner

box cover.

15 - Reconnect all wires.

16 - Reconnect top cap and vent pipe to combustion air

inducer outlet.

17 - Reconnect gas supply piping.

18 -

Turn on power and gas supply to unit.

19 - Set thermostat and check for proper operation.

20 - Check all piping connections, factory and field, for

gas leaks. Use a leak detecting solution or other

preferred means.

21 - If a leak is detected, shut gas and electricity off and

repair leak.

CAUTION

Some soaps used for leak detection are corrosive

to certain metals. Carefully rinse piping thoroughly

after leak test has been completed. Do not use

matches, candles, flame or other sources of ignition

to check for gas leaks.

22 - Repeat steps 21 and 23 until no leaks are detected.

23 - Replace access panel.

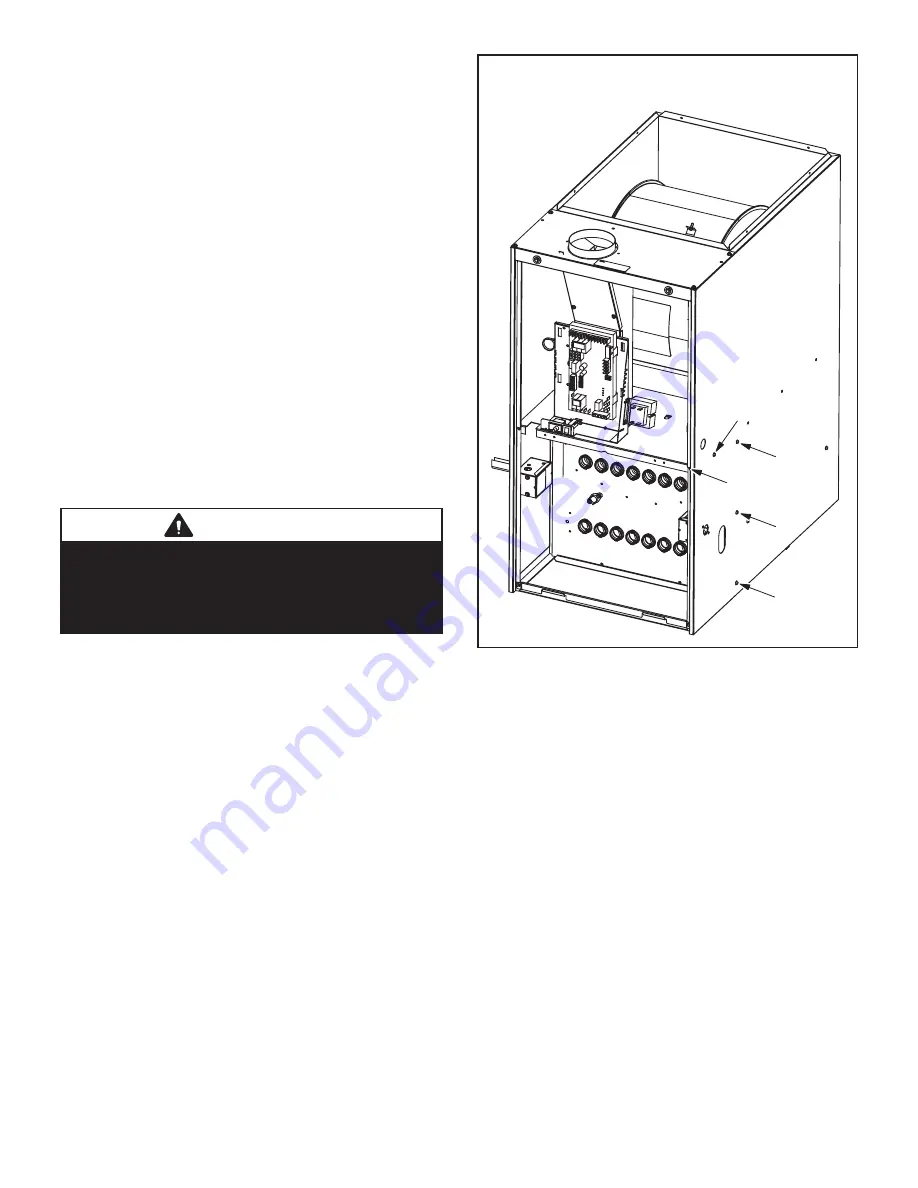

Remove five screws if necessary

(either side of cabinet)

1

2

3

4

5

FIGURE 25