Page 26

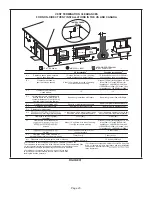

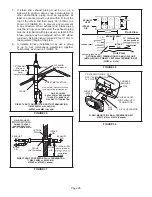

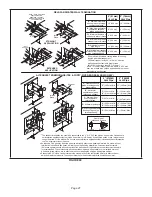

7 - If intake and exhaust piping must be run up a

side wall to position above snow accumulation or

other obstructions, piping must be supported. At

least one bracket must be used within 6” from the

top of the elbow and then every 24” (610mm) as

shown in FIGURE 40, to prevent any movement

in any direction. When exhaust and intake piping

must be run up an outside wall, the exhaust piping

must be terminated with pipe sized per table 8.The

intake piping may be equipped with a 90° elbow

turndown. Using turndown will add 5 feet (1.5m) to

the equivalent length of the pipe.

8 - A multiple furnace installation may use a group

of up to four terminations assembled together

horizontally, as shown in

FIGURE 38.

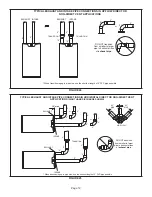

DIRECT VENT CONCENTRIC ROOFTOP TERMINATION

71M80, 69M29 or 60L46 (US)

44W92 or 44W93 (Canada)

Minimum

Above Average

Snow

Accumulation

SHEET METAL STRAP

(Clamp and sheet metal strap

must be field−installed to support

the weight of the termination kit.)

FLASHING

(Not Furnished)

CLAMP

FIELD-PROVIDED

REDUCER MAY BE REQUIRED

TO ADAPT LARGER VENT

PIPE SIZE TO TERMINATION

INTAKE

12” (305mm)

FIGURE 36

12” (305mm) Min.

above grade or

cumulation.

DIRECT VENT CONCENTRIC WALL TERMINATION

71M80, 69M29 or 60L46 (US)

41W92 or 41W93 (Canada)

INTAKE

AIR

EXHAUST

AIR

INTAKE

AIR

INTAKE

AIR

EXHAUST

AIR

OUTSIDE

WALL

GRADE

CLAMP

(Not Furnished)

FIELD-PROVIDED

QUIRED TO ADAPT

LARGER VENT PIPE

SIZE TO TERMINATION.

FIGURE 37

EXHAUST

VENT

INTAKE

AIR

5-1/2”

(140mm)

Front View

12”

(305mm)

5”

(127mm)

18” MAX.

(457mm)

EXHAUST VENT

INTAKE

AIR

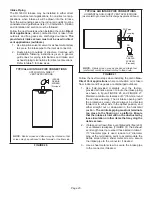

OPTIONAL VENT TERMINATION FOR MULTIPLE UNIT

INSTALLATION OF DIRECT VENT WALL TERMINATION KIT

(30G28 or 81J20)

Inches (mm)

Side View

12” (305mm) Min.

above grade or

cumulation.

optional intake elbow

FIGURE 38

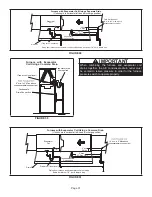

2” EXTENSION FOR 2” PVC

PIPE1” EXTENSION FOR 3”

PVC PIPE

1-1/2” ACCELERATOR

FURNACE

EXHAUST

PIPE

FURNACE

INTAKE

PIPE

4''

GLUE EXHAUST

END FLUSH INTO

TERMINATION

FLAT

SIDE

FLUSH-MOUNT SIDE WALL TERMINATION KIT

51W11 (US) or 51W12 (Canada)

FIGURE 39