Page 35

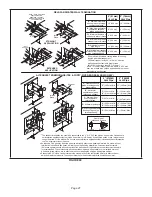

TABLE 9

Gas Pipe Capacity - ft3/hr (m3/hr)

Nominal

Iron Pipe

Size Inches

(mm)

Internal

Diameter

inches

(mm)

Length of Pipe - feet (m)

10

(3.048)

20

(6.096)

30

(9,144)

40

(12,192)

50

(15.240)

60

(18.288)

70

(21.336)

80

(24.384)

90

(27.432)

100

(30,480)

1/2

(12.7)

.622

(17.799)

172

(4.87)

118

(3.34)

95

(2.69)

81

(2.29)

72

(2.03)

65

(1.84)

60

(1.69)

56

(1.58)

52

(1.47)

50

(1.42)

3/4

(19.05)

.824

(20.930)

360

(10.19)

247

(7.000)

199

(5.63)

170

(4.81)

151

(4.23)

137

(3.87)

126

(3.56)

117

(3.31)

110

(3.11)

104

(2.94)

1

(25.4)

1.049

(26.645)

678

(19.19)

466

(13.19)

374

(10.59)

320

(9.06)

284

(8.04)

257

(7.27)

237

(6.71)

220

(6.23)

207

(5.86)

195

(5.52)

1-1/4

(31.75)

1.380

(35.052)

1350

(38.22)

957

(27.09)

768

(22.25)

657

(18.60)

583

(16.50)

528

(14.95)

486

(13.76)

452

(12.79)

424

(12.00)

400

(11.33)

1-1/2

(38.1)

1.610

(40.894)

2090

(59.18)

1430

(40.49)

1150

(32.56)

985

(27.89)

873

(24.72)

791

(22.39)

728

(20.61)

677

(19.17)

635

(17.98)

600

(17.00)

2

(50.8)

2.067

(52.502)

4020

(113.83)

2760

(78.15)

2220

(62.86)

1900

(53.80)

1680

(47.57)

1520

(43.04)

1400

(39.64)

1300

(36.81)

1220

(34.55)

1160

(32.844)

2-1/2

(63.5)

2.469

(67.713)

6400

(181.22)

4400

(124.59)

3530

(99.95)

3020

(85.51)

2680

(75.88)

2480

(70.22)

2230

(63.14)

2080

(58.89)

1950

(55.22)

1840

(52.10)

3

(76.2)

3.068

(77.927)

11300

(319.98)

7780

(220.30)

6250

(176.98)

5350

(151.49)

4740

(134.22)

4290

(121.47)

3950

(111.85)

3670

(103.92)

3450

(97.69)

3260

(92.31)

NOTE -

Capacity given in cubic feet (m3 ) of gas per hour and based on 0.60 specific gravity gas.

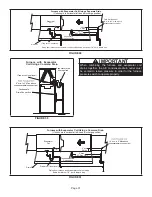

Removal of the Furnace from Common Vent

In the event that an existing furnace is removed from a

venting system commonly run with separate gas applianc-

es, the venting system is likely to be too large to properly

vent the remaining attached appliances.

Conduct the following test while each appliance is oper-

ating and the other appliances (which are not operating)

remain connected to the common venting system. If the

venting system has been installed improperly, you must

correct the system as indicated in the general venting re-

quirements section.

WARNING

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each

appliance connected to the venting system being placed

into operation could result in carbon monoxide poisoning

or death.

The following steps shall be followed for each appliance

connected to the venting system being placed into

operation, while all other appliances connected to the

venting system are not in operation:

1 - Seal any unused openings in the common venting

system.

2 -

Inspect the venting system for proper size and

horizontal pitch. Determine that there is no blockage,

restriction, leakage, corrosion, or other deficiencies

which could cause an unsafe condition.

3 -

Close all building doors and windows and all

doors between the space in which the appliances

remaining connected to the common venting system

are located and other spaces of the building. Turn on

clothes dryers and any appliances not connected to

the common venting system. Turn on any exhaust

fans, such as range hoods and bathroom exhausts,

so they will operate at maximum speed. Do not

operate a summer exhaust fan. Close fireplace

dampers.

4 - Follow the lighting instructions. Turn on the appliance

that is being inspected. Adjust the thermostat so

that the appliance operates continuously.

5 - After the main burner has operated for 5 minutes,

test for leaks of flue gases at the draft hood relief

opening. Use the flame of a match or candle.

6 - After determining that each appliance connected

to the common venting system is venting properly,

(step 3) return all doors, widows, exhaust fans,

fireplace dampers, and any other gas-burning

appliances to their previous mode of operation.

7 - If a venting problem is found during any of the

preceding tests, the common venting system must

be modified to correct the problem.

Resize the common venting system to the minimum

vent pipe size determined by using the appropriate

tables in Appendix G. (These are in the current stan-

dards of the National Fuel Gas Code ANSI Z223.1.