Page 13

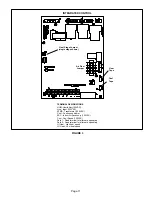

TABLE 5

Emerson Motor Only

PW

LED

RX

LED

TX

LED

Motor

Blower

Action

Off

Blink

Blink

Not

Rotating

Normal

Blink

Blink

Blink

Rotating

Normal. PW blink is 100cfm/blink

Blink

Off

Blink

Not

Rotating

Verify 16X4W and motor control hp match. Verify

power to motor control.

Turn off power for 1 minute then restart. If motor still

does not rotate replace the controller.

Off

Off

Off

Not

Rotating

Verify power to the 16X4W. Turn off power then restart.

If LED's are still out, replace controller.

Motor rpm is continually adjusted internally to maintain

constant cfm. The controller monitors the static work load on

the motor and motor amp‐draw to determine the amount of

rpm adjustment. Blower rpm may be adjusted any amount in

order to maintain a constant cfm as shown in Blower Ratings

Tables. The cfm remains relatively stable over a broad range

of static pressure. Since the blower constantly adjusts rpm to

maintain a specified cfm, motor rpm is not rated. Hence, the

terms “cool speed” , “heat speed ” or “speed tap” in this manu

al, on the unit wiring diagram and on blower B3, refer to blower

cfm regardless of motor rpm.

The unit control indicates the desired cfm. The blower will

maintain the desired cfm as long as external static pressure

does not exceed 0.8”. If the system exceeds this amount, the

blower

may

enter a “cut back”, mode wherein it then slows

down to protect itself from electrical damage. During this “cut

back” mode the unit control will still indicate the

same

desired

cfm regardless of actual motor rpm.

When Harmony is used, speed taps are overridden and a

PWM signal generated by the Harmony controller continuous

ly varies motor speed based upon zone demands.

Initial Power Up

When line voltage is applied to B3, there will be a large inrush

of power lasting less than 1/4 second. This inrush charges a

bank of DC filter capacitors inside the controller. If the discon

nect switch is bounced when the disconnect is closed, the dis

connect contacts may become welded. Try not to bounce the

disconnect switch when applying power to the unit.

Motor Start‐Up

When B3 begins start‐up, the motor gently vibrates back and

forth for a moment. This is normal. During this time the elec

tronic controller is determining the exact position of the rotor.

Once the motor begins turning, the controller slowly eases

the motor up to speed (this is called “soft‐start”). The motor

may take as long as 10‐15 seconds to reach full speed. If the

motor does not reach 200rpm within 13 seconds, the motor

shuts down. Then the motor will immediately attempt a re

start. The shutdown feature provides protection in case of a

frozen bearing or blocked blower wheel. The motor may at

tempt to start eight times. If the motor does not start after the

eighth try, the controller locks out. Reset controller by momen

tarily turning off power to unit.

The DC filter capacitors inside the controller are connected

electrically to the speed tap wires. The capacitors take

approximately 5 minutes to discharge when the disconnect

is opened. For this reason it is necessary to wait at least 5

minutes after turning off power to the unit before attempt

ing to change speed taps.

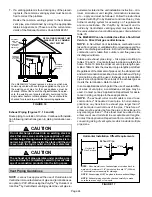

DANGER

Disconnect power from unit and

wait at least five minutes to allow

capacitors to discharge before at

tempting to adjust motor speed tap

settings. Failure to wait may cause

personal injury or death.

External Operation (Speed Tap Priority)

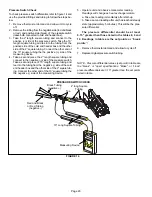

Figures 8 and 9 show the two quick‐connect jacks (J48 and

J49) which connect the motor to the ML296UHV. Jack J48

is the power plug and jack J49 connects the unit controls to

the motor.

Jack J48 is the power plug. Line voltage must be applied to

J48 pins 4 and 5 in order for the motor to operate. When

using 120VAC pins 1 and 2 must be jumpered.

Jack J49 connects the unit controls to the motor. The motor

assigns priority to J49 pin 2 so that if a call for cooling and a

call for heating are concurrent, heating call overrides and

the blower operates on high speed heating tap.