Page 16

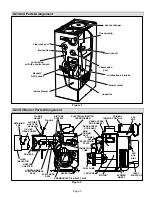

Unit Start−Up & Adjustments

Before starting unit, make sure the oil tank is adequately

filled with clean No. 1 or No. 2 furnace oil.

NOTE − Water, rust or other contaminants in oil supply sys-

tem will cause malfunction and failure of the internal parts

of the fuel pump.

CAUTION

Never burn garbage or paper in the heating system.

Never leave papers near or around the unit.

CAUTION

Blower door must be in place before start−up.

1− Set thermostat for heating demand and turn on electri-

cal supply to unit.

2− Check initial air adjustment. All units are equipped with

an air adjustment dial on the right side of the burner.

See burner parts arrangement illustration.

3− Turn unit on. Place a can or container under the bleed

port located on the fuel pump. Loosen nut on bleed port

to release air and oil mixture from fuel line. Allow mix-

ture to escape until a steady stream of oil is emitted

from the port. Drain at least 1/2 pint of oil from the

pump. Retighten the nut on bleed port. If lockout oc-

curs, press reset button and continue with bleed proce-

dure.

NOTE − A two−pipe fuel system will normally bleed itself

by forcing air back to the tank through the return line.

This type of bleeding procedure is not necessary.

4− If burner fails to start, push reset button on primary

safety control and the burner motor reset button. See

part arrangement illustration.

CAUTION

Do not push the reset button on the primary control

more than one time.

5− If the burner fails to light again, refer to the trouble-

shooting section in this manual.

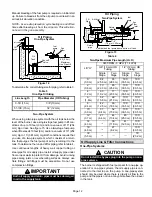

A − Fuel Pump Pressure

Measure fuel pump pressure with unit off. Attach pressure

gauge to pump outlet. Turn unit on and check pressure and

compare to table 6. Adjust if necessary.

B − Temperature Rise

To measure temperature rise, place plenum thermometers

in warm air and return air plenums. Locate thermometer in

warm air plenum where thermometer will not see" the heat

exchanger to prevent it from picking up radiant heat. Set

thermostat to its highest setting to start unit. After plenum

thermometers have reached their highest and steadiest

readings, subtract the readings. The difference in tempera-

tures in the supply and return air plenums should approxi-

mate the temperature rise range listed in table 6 and the ap-

pliance rating plate. If not, adjust the blower motor pulley to

adjust the blower speed.

Table 6

O23

Unit

nozzle size,

spray

angle,

& pattern

pump

PSIG

input

rating

BTU/HR

output

rating

BTU/HR

head

temp

rise

F°

−70

.50GPH−80° A

100

70,000

57,000

FB0

60−70

−105

.65GPH−80° B

140

105,000

84,000

FB3

65−75

−120

.75GPH−80° B

140

119,000

105,000

FB3

70−80

−140

.85GPH−80° B

140

140,000

112,000

FB6

65−75

−154

1.0GPH−80° B

140

154,000

125,000

FB6

70−80

C − Limit Control

Limit Control − Do not adjust it from factory setting.

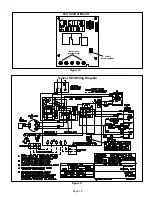

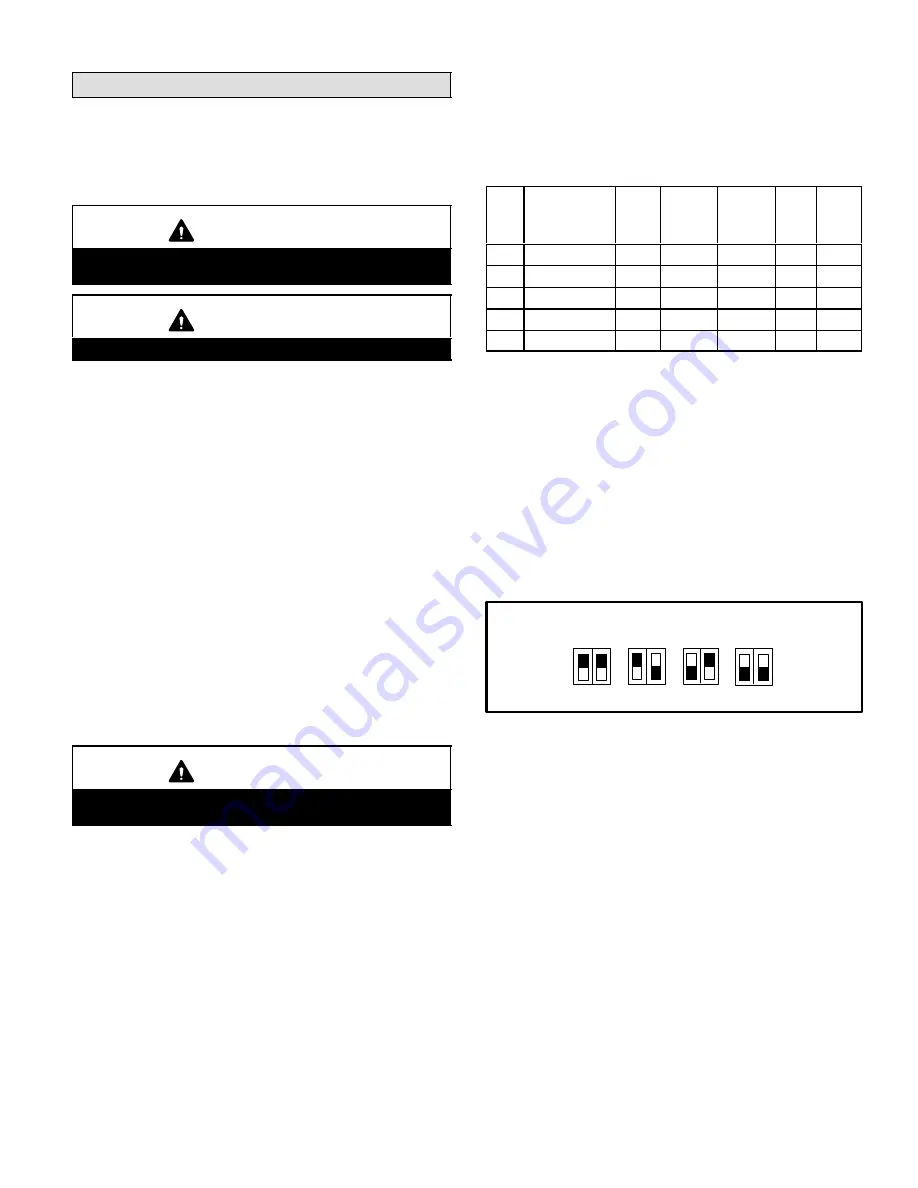

D − Fan Control

The fan on time of 30 seconds is not adjustable. Fan off

time (time that the blower operates after the heat demand

has been satisfied) can be adjusted by moving the delay

switches on the fan control board. Fan off time will affect

comfort and is adjustable to satisfy individual applications.

See figure 19. Set the heat fan off delay switches to either

60, 90, 120, or 150 seconds. The factory setting is 90 sec-

onds.

150 sec

Figure 19

Fan Off Delay Switch Settings

120 sec

90 sec

60 sec

E − Burner Adjustment

The following instructions are essential to the proper op-

eration of O23 series oil furnaces. To prevent sooting,

these instructions must be followed in sequence:

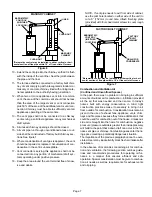

1 − Draft

This test should be taken at the breach between the outlet

of the vent connector and the barometric draft control. Gen-

erally a 1/4" hole will need to be drilled for the draft gauge to

be inserted into the vent connector.

A minimum of 0.03 draft must be established without the

burner in operation. With the burner in operation, the draft

should be 0.04 to 0.05. This is VERY critical to the flame

retention head burners.

Oil furnace installations also require careful inspection to

make sure the chimney is in good shape and can accom-

modate the products of combustion. The temperature in

the unconditioned space will also affect the draft if long vent

connectors are allowed to get too cold.