Page 18

Troubleshooting

Burner failure or improper operation can result from a num-

ber of different causes.

Often the cause can be pinpointed by observing the differ-

ent types of failure or by the process of elimination. The fol-

lowing troubleshooting charts list some failures, causes

and a sequence of steps to isolate the point of failure.

Check the simplest and most obvious items before prog-

ressing to other items.

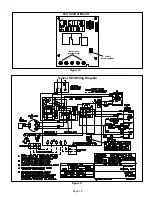

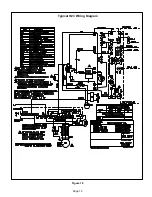

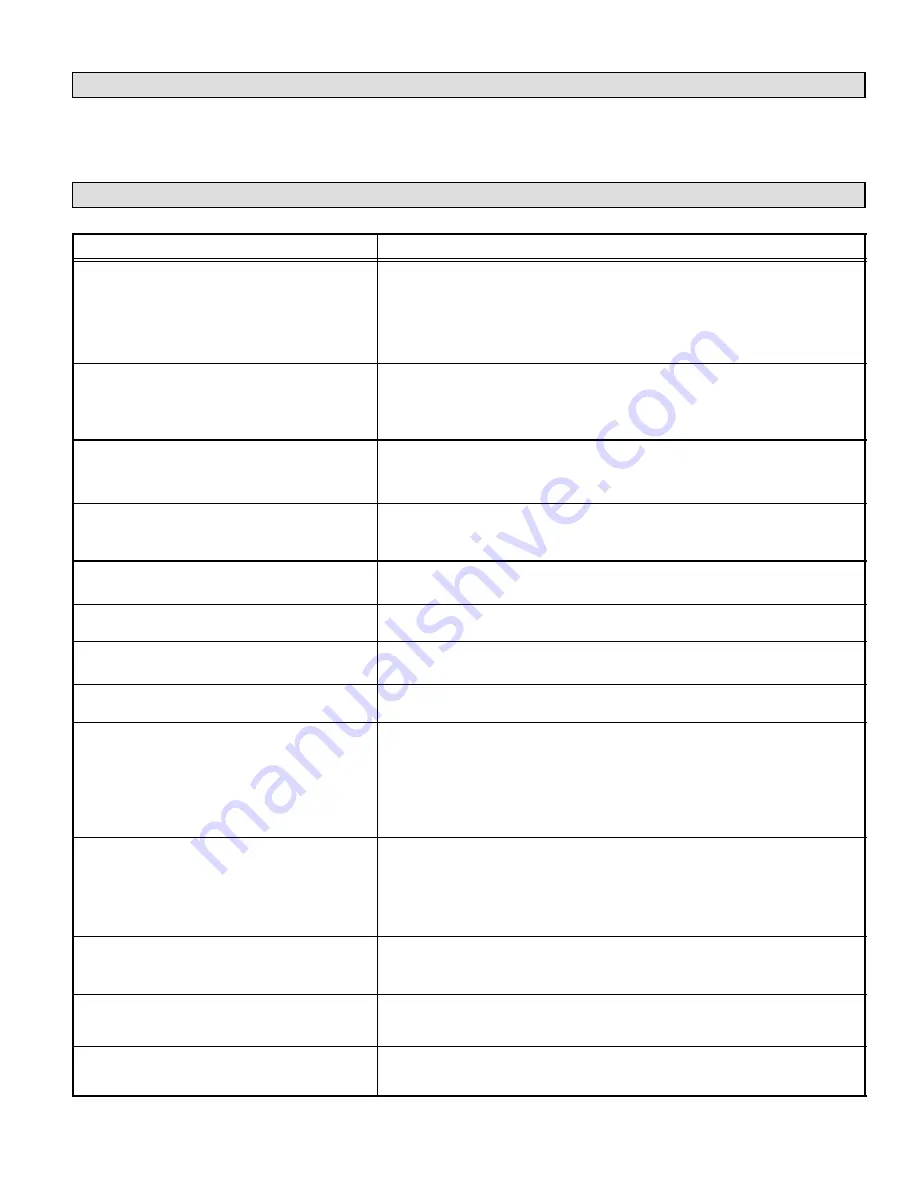

Troubleshooting: Fan board operating sequence

Action

System Response

Thermostat calls for heat.

(W terminal is energized.)

ST9103A closes oil primary control T−T connections.

Ignition system and oil primary control start the furnace. Oil flows as long as oil primary

control senses flame.

Burner motor is energized and heat fan on delay timing begins. When timing is complete,

the circulating fan is energized at heat speed and warm air is delivered to the controlled

space.

Thermostat ends call for heat.

(W terminal is de−energized.)

Oil primary control is de−energized, terminating the burner cycle.

Heat fan off delay timing begins. When timing is complete, the circulating fan is de−ener-

gized.

ST9103A returns to standby mode (oil primary control and circulating fan are off).

Burner fails to light.

Oil primary control locks out within lockout timing (timing depends on oil primary control).

Burner motor is de−energized.

If heat fan has started, it continues through the selected delay off period.

Established flame fails.

Burner motor is de−energized and oil primary control goes into recycle mode.

If selected heat fan off delay is longer than the recycle delay timing, the heat fan contin-

ues to run through the next trial for ignition.

Thermostat begins call for cool.

(G and Y terminals are energized.)

Circulating fan is energized at the cool speed.

Cooling compressor turns on immediately.

Thermostat ends call for cool.

(G and Y terminals are de−energized.)

Circulating fan and cooling compressor turn off immediately.

Thermostat begins call for fan.

(G terminal is energized.)

Circulating fan is energized immediately at cool speed.

ST9103A may be factory−configured to operate heat speed in this mode.

Thermostat ends call for fan.

(G terminal is de−energized.)

Circulating fan is de−energized.

Limit switch string opens.

Oil primary control shut off the burner.

Circulating fan is energized immediately at heat speed.

ST9103A opens oil primary control T−T connections.

Circulating fan runs as long as limit string stays open.

If there is a call for cooling or fan, the circulating fan switches from heat speed to cool

speed.

Limit switch string closes.

ST9103A begins heat fan off delay sequence.

Circulating fan turns off after the selected heat fan off delay timing.

ST9103A closes oil primary control T−T connections.

Oil primary control is energized, initiating burner light off.

Continuous circulating fan is connected.

(Optional connectors are available for separate circu-

lating fan speed tap.)

Circulating fan is energized at low speed when there is no call for heat, cool or fan.

If fan operation is required by a call for heat, cool, or fan, the ST9103A switches off the

continuous fan speed tap before energizing the other fan speed.

Electronic air cleaner is connected.

(Optional connectors are available for 120 Vac elec-

tronic air cleaner.)

Electronic air cleaner (EAC) connections are energized when the heat or cool speed of

the circulating fan is energized. EAC connections are

not

energized when the optional

continuous fan terminal is energized.

Humidity control is connected.

(Optional connectors are available for 120 Vac humidi-

fier.)

Humidifier connections are energized when the burner motor is energized.