Page 23

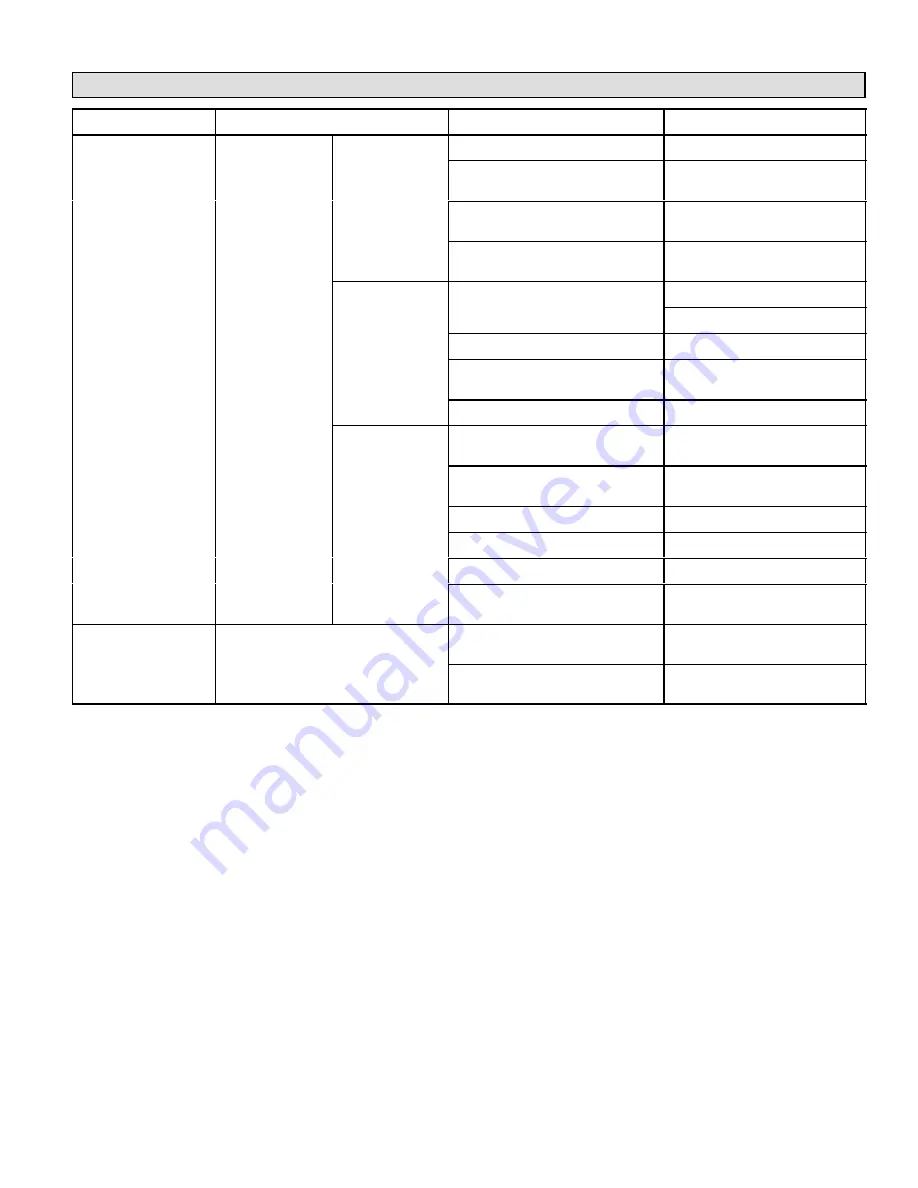

Troubleshooting: Burner runs continuously (too little heat).

Source

Procedure

Causes

Correction

Too much combustion air

Reduce combustion air.

Low CO

2

less

Air leaks into heat exchanger

around inspection door, etc.

Correct cause of air leak.

Low CO

2

less

than 10%.

Excessive draft

Adjust barometric draft con-

trol for correct draft.

Incorrect burner head adjust-

ment

Correct burner head setting.

Dirty or plugged heat exchanger

Clean heat exchanger.

Hi h

k

Dirty or plugged heat exchanger

Readjust burner.

Check burner

High smoke

reading more

Insufficient draft

Increase draft.

Combustion

Check burner

combustion for

CO2, stack tem-

reading more

than a trace.

Incorrect burner head adjust-

ment

Correct burner setting.

CO2, stack tem

perature, and

smoke

Too little combustion air

Increase combustion air.

smoke

Too little blower air

Increase blower speed to

maintain proper temp. rise.

High stack tem-

Blower belt too loose (if

equipped)

Tighten blower belt.

High stack tem-

perature is

more than

Dirty or plugged heat exchanger Clean heat exchanger.

more than

550

_

F Net.

Dirty blower wheel

Clean blower wheel.

550 F Net.

Dirty furnace air filters

Clean or replace filter.

Restricted or closed registers or

dampers

Readjust registers or damp-

ers.

Oil Pressure

Inspect fire and check

Partially plugged or defective

nozzle

Replace nozzle.

Oil Pressure

Inspect fire and check

oil pressure.

Oil pressure is too low: less

than 100 psi.

Increase oil pressure top

100psi.