Page 6

To check nozzle alignment, again insert the small end into

the end cone and measure the nozzle and electrode align-

ment against the center lines marked on the gauge (again

refer to enclosed illustration sheet). If the nozzle is not cen-

tered, but found to be too far left or right, a new nozzle as-

sembly will need to be ordered. Do not attempt to adjust by

bending the 90 degree elbow in the oil line.

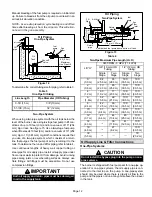

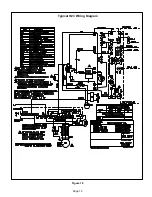

Figure 4

Beckett Oil Burner Nozzle Adjustment

TO ADJUST NOZZLE:

Burner must be removed from

furnace for this procedure.

GAUGE

1−Loosen screw.

2−Slide entire nozzle/electrode assembly back and forth until

nozzle just touches gauge.

1

2

Venting

WARNING

Combustion air openings in front of the furnace must

be kept free of obstructions. Any obstruction will

cause improper burner operation and may result in

a fire hazard.

WARNING

The barometric damper shall be in the same atmo-

spheric pressure zone as the combustion air inlet to

the furnace. Deviation from this practice will cause

improper burner operation and may result in a fire

hazard.

CAUTION

Do not store combustible materials near the furnace

or supply air ducts. The material (such as paint, mo-

tor oil, gasoline, paint thinner, etc.) may ignite by

spontaneous combustion creating a fire hazard.

WARNING

This furnace is certified for use with type L" vent.

B" vent must not be used with oil furnaces.

NOTE − Oil burning equipment may be vented into an ap-

proved masonry chimney or type L vent. (Type L vent is

similar in construction to type B gas vent except it carries a

higher temperature rating and is constructed with an inner

liner of stainless steel rather than aluminum).

Prior to installation of unit, make a thorough inspection of

the chimney to determine whether repairs are necessary.

Make sure the chimney is properly constructed and sized

according to the requirements of the National Fire Protec-

tion Association. The smallest dimensions of the chimney

should be at least equal to the diameter of the furnace vent

connector. Make sure the chimney will produce a steady

draft sufficient to remove all the products of combustion

from the furnace. A draft of at least .04" w.c. (9.9 Pa) is re-

quired during burner operation.

1 − Local building codes may have more stringent installa-

tion requirements and should be consulted before

installation of unit.

2 − The vent connector should be as short as possible to

do the job.

3 − The vent connector should not be smaller than the out-

let diameter of the vent outlet of the furnace.

4 − Pipe should be at least 24 gauge galvanized.

5 − Single wall vent pipe should not run outside or through

any unconditioned space.

6 − Chimney should extend 3 feet (0.9 m) above highest

point where the vent passes through the roof, and 2

feet (0.6 m) higher than any portion of a building within

a horizontal distance of 10 feet (3 m).

7 − The vent must not pass through a floor or ceiling.

Clearances to single wall vent pipe should be no less

than 6" (152 mm); more if local codes require it.

8 − The vent may pass through a wall where provisions

have been made for a thimble as specified in the Stan-

dards of the National Board of Fire Underwriters. See

figure 5.

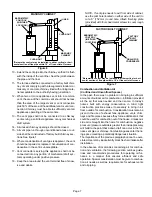

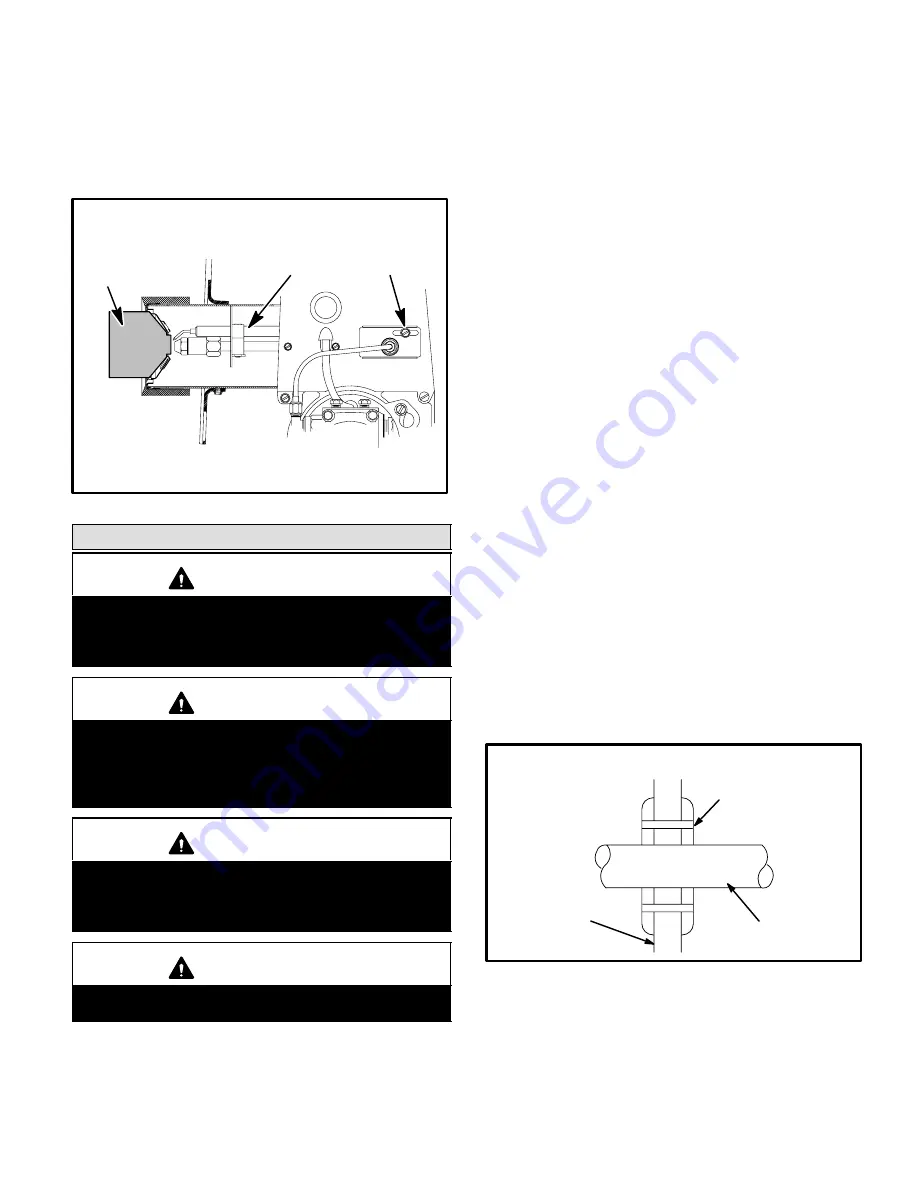

WALL THIMBLE

FIGURE 5

THIMBLE

VENT PIPE

COMBUSTIBLE

WALL

9 − The vent pipe should slope upward toward the chim-

ney on horizontal run at least 1/4 inch (6 mm) to the

foot (0.3 m) and should be supported by something

other than the furnace, such as isolation hangers. See

figure 6.