Page 7

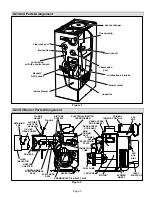

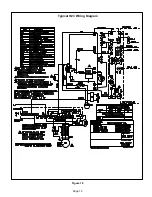

MASONRY CHIMNEY

BAROMETRIC

CONTROL*

(IN EITHER

LOCATION)

CLEAN OUT

CLEAN OUT

LINER

MASONRY

CHIMNEY

Figure 6

*Barometric control may be installed in either vertical or hori-

zontal section of flue pipe within 18" of flue outlet of furnace.

10− Extend the vent pipe into the chimney so that it is flush

with the inside of the vent liner. Seal the joint between

the pipe and the liner.

11− The furnace shall be connected to a factory built chim-

ney or vent complying with a recognized standard, or

masonry or concrete chimney lined with a lining mate-

rial acceptable to the authority having jurisdiction.

12− When two or more appliances vent into a common

vent, the area of the common vent should not be less

than the area of the largest vent or vent connection

plus 50% of the area of the additional vent or vent con-

nection. Chimney must be able to sufficiently vent all

appliances operating at the same time.

13− The vent pipe shall not be connected to a chimney

vent serving a solid fuel appliance or any mechanical

draft system.

14− All unused chimney openings should be closed.

15− All vent pipe run through unconditioned areas or out-

side shall be constructed of factory built chimney sec-

tions. See figure 7.

16− Where condensation of vent gas is apparent, the vent

should be repaired or replaced. Accumulation of con-

densation in the vent is unacceptable.

17− Vent connectors serving this appliance shall not be

connected into any portion of mechanical draft sys-

tems operating under positive pressure.

18− Keep the area around the vent terminal free of snow,

ice and debris.

NOTE − If vent pipe needs to exit from side of cabinet,

use the pilot hole (located on either side of the unit) to

cut a 6" (152 mm) round hole. Attach finishing plate

(provided) with four sheet metal screws to cover rough

edges.

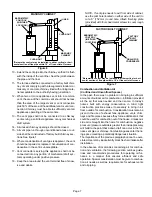

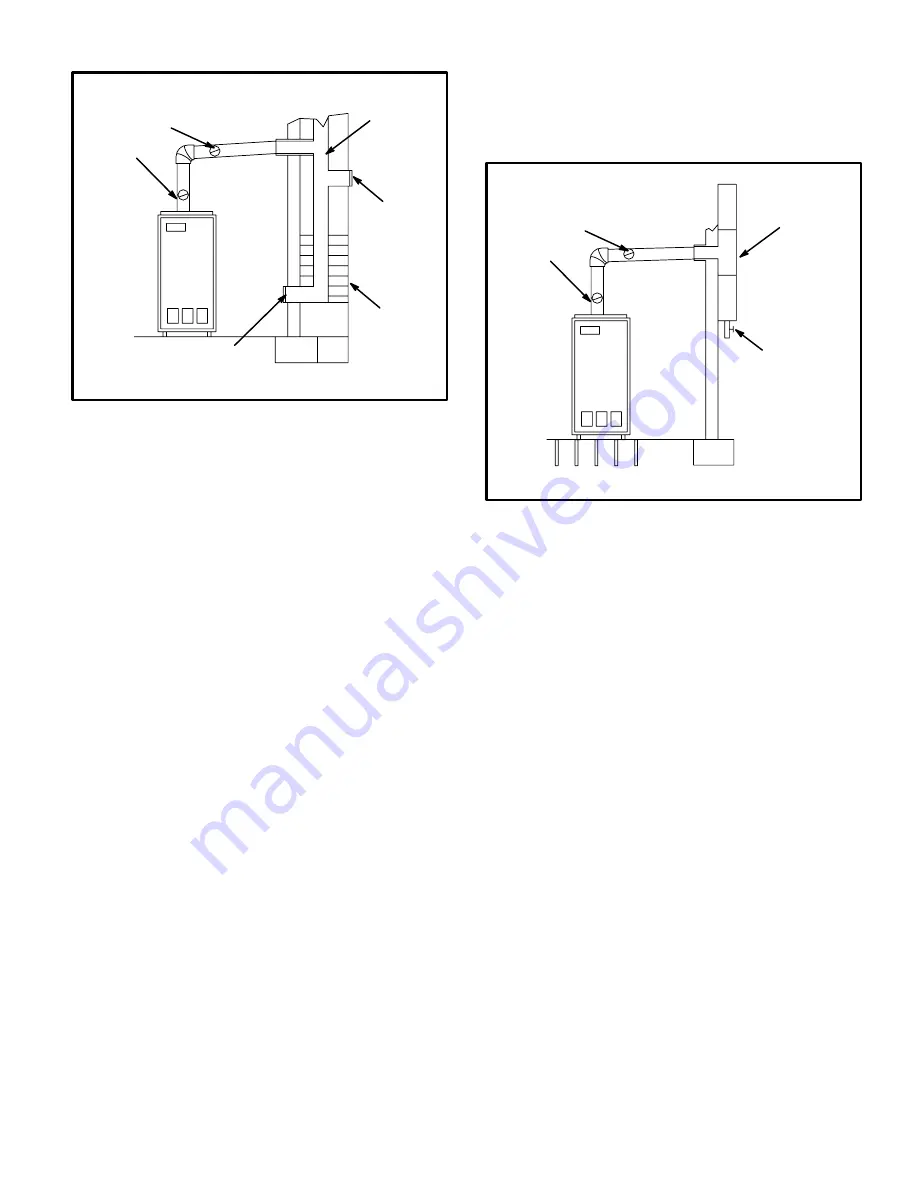

FACTORY−BUILT CHIMNEY

BAROMETRIC

CONTROL*

(IN EITHER

LOCATION)

DRAIN FOR

CONDENSATE

FACTORY

BUILT

CHIMNEY

Figure 7

*Barometric control may be installed in either vertical or hori-

zontal section of flue pipe within 18" of flue outlet of furnace.

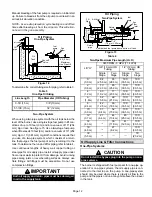

Combustion and Ventilation Air

(Confined and Unconfined Spaces)

In the past, there was no problem in bringing in sufficient

amounts of outdoor air for combustion − infiltration provided

all the air that was needed and then some. In today’s

homes built with energy conservation in mind, tight

construction practices make it necessary to bring in air

from outside for combustion. Consideration must also be

given to the use of exhaust fans, appliance vents, chim-

neys and fireplaces because they force additional air that

could be used for combustion out of the house. Unless out-

side air is brought into the home for combustion, negative

pressure (pressure outside is greater than inside pressure)

will build to the point that a down draft can occur in the fur-

nace vent pipe or chimney. Combustion gases enter the liv-

ing space creating a potentially dangerous situation.

The importance of the previous paragraph cannot be over-

stated. Users may inadvertently block fresh air intakes after

installation.

In the absence of local codes concerning air for combus-

tion and ventilation, the following section outlines guide-

lines and recommends procedures for operating oil fur-

naces in a manner that ensures efficient and safe

operation. Special consideration must be given to combus-

tion air needs as well as requirements for exhaust vents

and oil piping.