Page 18

those things which might affect combustion. Those

things which might affect combustion can then do so

without causing the unit to start sooting/smoking.

Things which might affect combustion include a nozzle

going bad, draft that changes during different climatic

conditions, dirty oil, dirt obstructing the air inlet, etc.

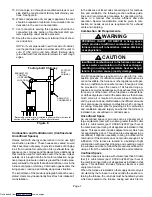

To build in a window of operation," set up the burner to

be 2% less in CO

2

. For example, if you find a reading of

12% CO

2

, adjust the air inlet shutter to increase the air

and drop the CO

2

to 10%.

5.

Retest the Smoke

With a drop in the CO

2

and in-

crease in the air you should see that the smoke has re-

turned to 0.

6.

Retest the Overfire Draft

This test serves to con-

firm that you have not increased the air too much.

Again you do not want a positive pressure at the test

port. It should still be 0.02 less than the draft pressure

reading taken at the breach. You may need to increase

the stack draft by adjusting the barometric draft con-

trol.

7.

Stack Temperature

Take a stack temperature

reading in the vent pipe. Subtract the room air temper-

ature from the stack temperature. This will give you the

net stack temperature. Use the efficiency charts pro-

vided in most CO

2

analyzers to determine furnace effi-

ciency.

Service

CAUTION

Do not tamper with unit controls. Call your qualified

service technician.

Servicing the Air Filter

NOTE − Under no circumstances should the access panels

to the blower compartment be left off or left partially open.

Throw-Away Type Filters

Check filters monthly and re-

place when necessary to assure proper furnace operation.

Replace filters with like kind and size filters.

Reusable Type Filters

Filters should be checked

monthly and cleaned when necessary to assure proper fur-

nace operation.

Servicing the Blower

Blower motor is prelubricated and sealed for extended op-

eration. No further lubrication is required. Disconnect pow-

er to unit before cleaning blower wheel for debris.

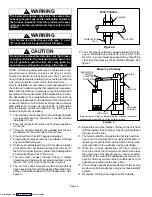

Inspecting the Flue Pipe

The flue pipe should be inspected annually by a qualified

service technician. Remove and clean any soot or ash

found in the flue pipe. Inspect pipe for holes or rusted

areas. If replacement is necessary, replace with the same

size and type as required by code. Inspect the flue draft

control device and replace if found defective.

Cleaning the Heat Exchanger

1. Remove the vent pipe from the furnace.

2. Remove the locking screws and the caps from the

clean out tubes. Remove flue access elbow.

3. Using a long spiral wire brush, sweep down the outer

drum of the heat exchanger. Then using the hose at-

tachment, vacuum out loose debris.

4. Remove the locking screw and cap from the observa-

tion tube and with the spiral wire brush, reach upward

toward the rear of the heat exchanger to clean out the

crossover tube.

CAUTION

Do not attempt to clean the combustion chamber. It

can be easily damaged.

5. Replace the three clean out caps and flue access el-

bow. Make sure locking screws are secure.

6. Brush out and vacuum the vent outlet area of the outer

drum and replace vent pipe.

7. Clean around the burner, blower deck and vestibule

area.

NOTE − A heat exchanger clean-out kit ABRSH380

(35K09) is available from Lennox.

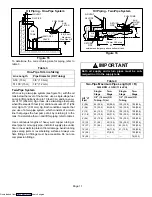

Servicing the Oil Burner

The nozzle and oil filter must be checked before each heat-

ing season. Also, recheck the conditions shown in the Oil

Furnace Start−up Checklist (see page 24).

NOTE − Close the oil line shutoff valve if the burner is shut

down for an extended period of time.

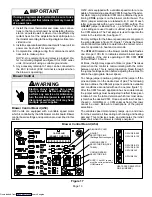

Heating Events − Actions & Responses

1.

Action: Thermostat calls for heat

(W terminal is en-

ergized)

Response:

D

Blower control board closes oil primary control

T−3T connections.

D

After a 15−second pre−purge period, power is sent

to the burner and ignition is established. When the

burner pump reaches full speed, the solenoid

valve is energized.

D

Ignition system and oil primary control start the

furnace. Oil flows as long as oil primary control

senses flame.

D

Burner motor energized and heat fan on ramp tim-

ing begins. When timing is complete, the circulat-

ing fan is at heat speed and warm air is delivered to

the controlled space.

2.

Action: Thermostat ends call for heat

(W terminal

is de−energized)

Response:

D

Oil primary control is de−energized, terminating

the burner cycle.

D

Heat fan off ramp timing begins. When timing is

complete, circulating fan is de−energized.

D

Blower control board returns to standby mode (oil

primary control and circulating fan are off).

D

After the thermostat is satisfied, the thermostat

circuit opens. The solenoid valve is de−energized

before the pump rotation stops. Power to the burn-

er is interrupted, shutting down the burner.

3.

Action: Burner fails to light

Response:

D

Oil primary control locks out within lockout timing

(timing depends on oil primary control).

Downloaded from