Page 10

or at the return air duct connection can cause a potentially

dangerous negative pressure condition. Air for combustion

and ventilation can be brought into the confined space ei-

ther from inside the building or from outside.

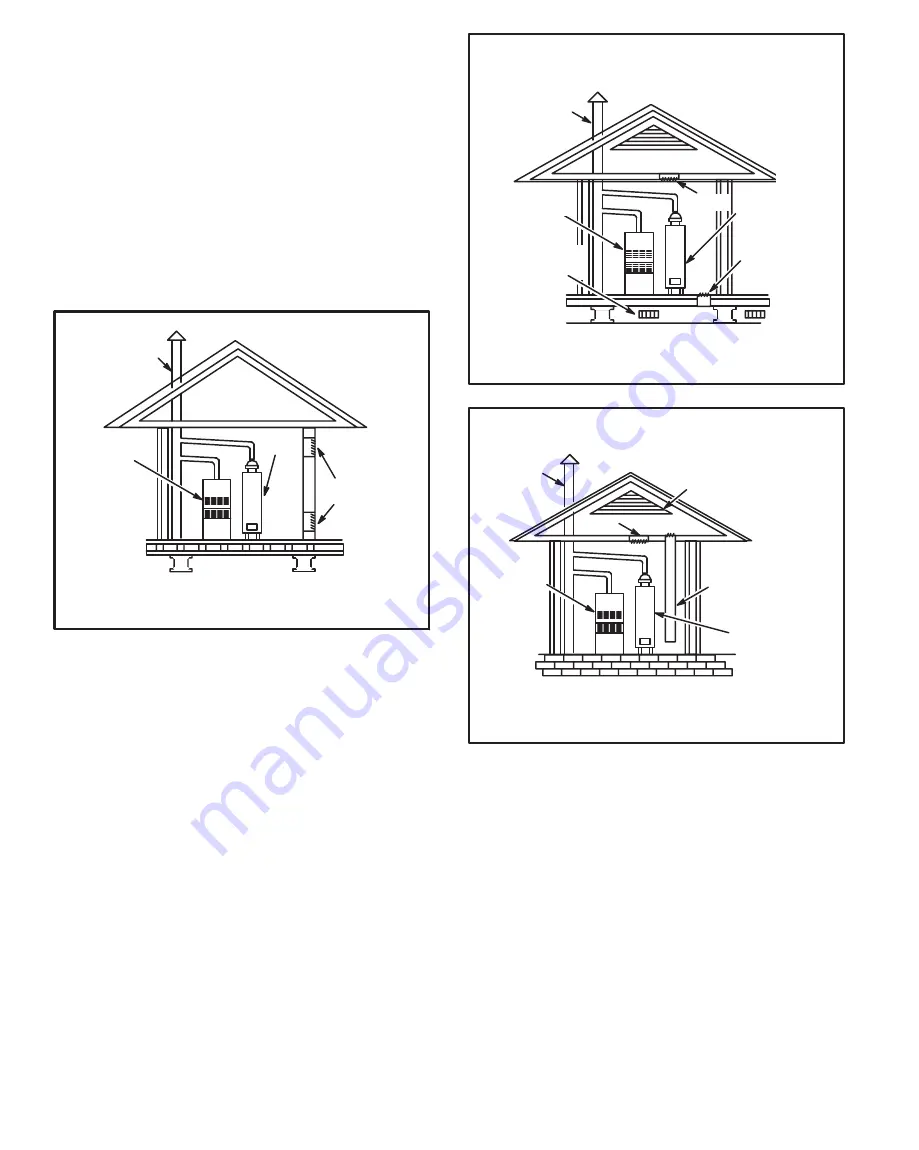

Air from an Adjacent Space

If the confined space housing the furnace adjoins space

categorized as unconfined, air can be brought in by provid-

ing two permanent openings between the two spaces.

Each opening must have a minimum free area of 1 square

inch

(6.4 square centimeters) per 1,000 Btu (293 W) per

hour of the total input rating of all fuel-fired equipment in the

confined space. Each opening must be at least 100 square

inches (614.5 square centimeters). One opening shall be

within 12" (305 mm) of the top of the enclosure and one

opening within 12" (305 mm) of the bottom (See figure 10).

Equipment In Confined Space

All Air From Inside

CHIMNEY OR

OIL VENT

WATER

HEATER

OPENINGS

(To Adjacent Room)

Figure 10

NOTE Each opening shall have a free area of at least 1 square inch

(6.4 square centimeters) per 1,000 Btu (293 W) per hour of the total

input rating of all equipment in the enclosure, but not less than 100

square inches

(614.5 square centimeters).

OIL

FURNACE

Air from Outside

If air from outside is brought in for combustion and ventila-

tion, the confined space shall be provided with two perma-

nent openings. One opening shall be within 12" (305 mm)

of the top of the enclosure and one within 12" (305 mm) of

the bottom. These openings must communicate directly or

by ducts with the outdoors or spaces (crawl or attic) that

freely communicate with the outdoors or indirectly through

vertical ducts. Each opening shall have a minimum free

area of 1 square inch (6.4 square centimeters) per 4,000

Btu (1172 W) per hour of total input rating of all equipment

in the enclosure (See figures 11 and 12). When communi-

cating with the outdoors through horizontal ducts, each

opening shall have a minimum free area of 1 square inch

(6.4 square centimeters) per 2,000 Btu (586 W) per total in-

put rating of all equipment in the enclosure (See figure 13).

Equipment In Confined Space

All Air From Outsid

e

(Inlet Air from Crawl Space and

Outlet Air to Ventilated Attic)

NOTE The inlet and outlet air openings shall each have a free area of

at least one square inch (6.4 square centimeters) per 4,000 Btu (1172

W) per hour of the total input rating of all equipment in the enclosure.

VENTILATION LOUVERS

(Each end of attic)

OUTLET

AIR

WATER

HEATER

INLET

AIR

CHIMNEY

OR OIL

VENT

VENTILATION

LOUVERS

(For unheated

crawl space)

Figure 11

OIL

FURNACE

Equipment In Confined Space

All Air From Outside

(All Air Through Ventilated Attic)

NOTE The inlet and outlet air openings shall each have a free area of at

least one square inch (6.4 square centimeters) per 4,000 Btu (1172 W)

per hour of the total input rating of all equipment in the enclosure.

CHIMNEY

OR OIL

VENT

WATER

HEATER

OUTLET

AIR

VENTILATION LOUVERS

(Each end of attic)

INLET AIR

(Ends 12" above

bottom)

Figure 12

OIL

FURNACE