Page 14

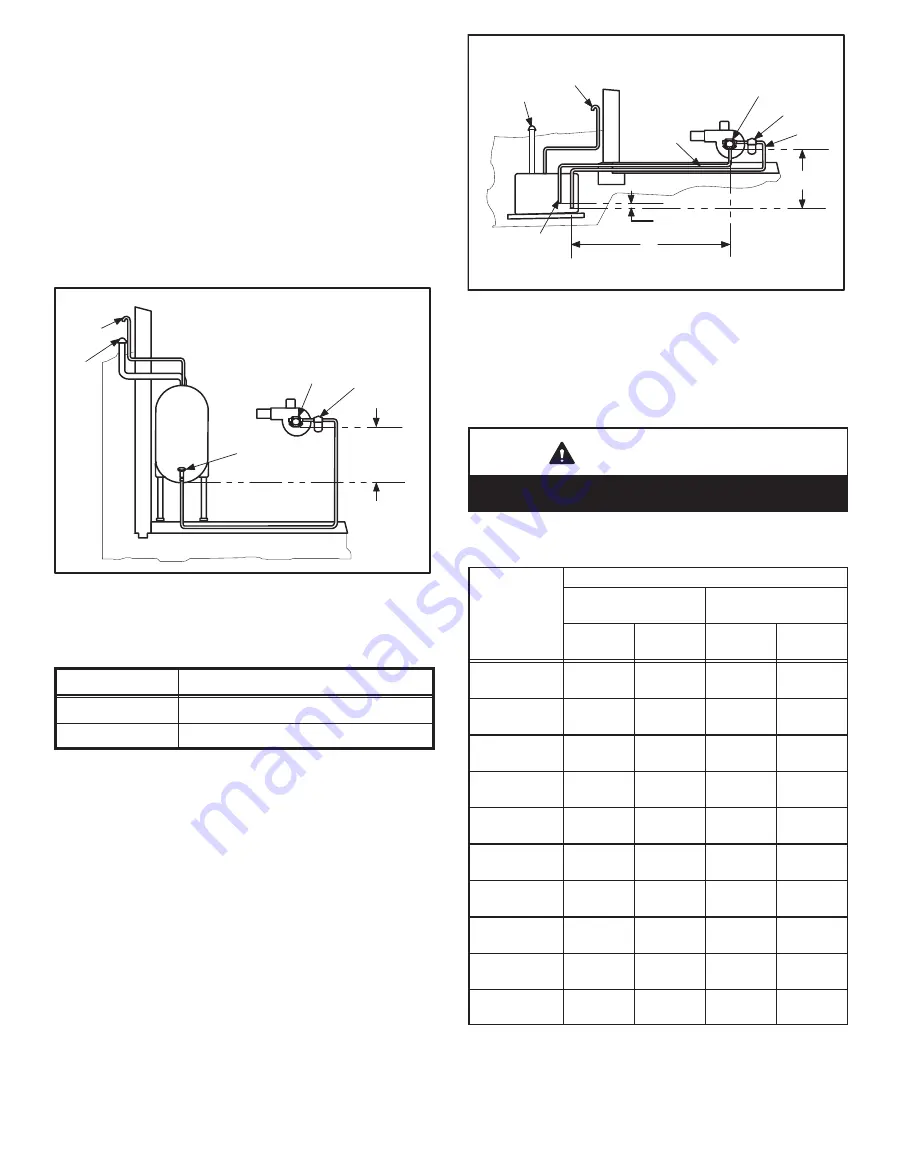

One−Pipe System

When using a one−pipe system with the oil tank even above

the burner and a vacuum of 6" (152 mm) Hg or less, a single−

stage fuel pump with a supply line and no return line should be

adequate. See figure 16. Manual bleeding of the fuel pump is

required on initial start up. Failure to bleed air from the oil pump

could result in an air lock/oil starvation condition.

NOTE − As an extra precaution, cycle heating on and off

ten times after bleeding air from the oil pump. This will

eliminate air in the gun assembly.

Figure 16

Oil Piping

ÎÎ

ÎÎ

ÎÎ

ÎÎ

ÎÎ

ÎÎ

ÎÎ

ÎÎÎÎÎÎÎÎÎÎÎ

ÎÎÎÎÎÎÎÎÎÎÎÎ

Î

Î

air vent

fill

pipe

Oil

Tank

fuel

pump

Aux

Filter

Shut off

Valve

8 ft (2.4 m)

Maximum

One Pipe Lift

One-Pipe System

Table 4

One−pipe Oil Sizing

Line Length

Pipe Diameter (OD Tubing)

0−50’ (15 m)

3/8" (10 mm)

51−100’ (15 m)

1/2" (12 mm)

Two−Pipe System

When using a two−pipe system with the oil tank below

the level of the burner, a single−stage fuel pump should

be used in lift conditions of up to 10 feet (3 m) and/or a

vacuum of 10" (254 mm) Hg or less. See figure 17. Use a

two−stage fuel pump when lift exceeds 10 feet (3 m) and/

or a vacuum of 10" (254 mm) Hg to 15" (381 mm) Hg. Both

conditions require that you use a two−pipe system, which con-

sists of a return line that purges the fuel pump of air by return-

ing it to the tank. To determine the run and lift for piping, refer to

table 5 .

To determine the length of the run for piping, refer to table 4 .

Figure 17

Oil Piping

ÎÎÎÎÎ

ÎÎÎÎÎ

ÎÎ

ÎÎÎÎÎÎÎÎÎÎ

ÎÎ

ÎÎ

ÎÎ

ÎÎ

ÎÎÎ

fuel

pump

Aux

Filter

Return

pipe

Fill

Pipe

Air Vent

Oil

Tank

Inlet

Return

pipe

H

3" 4"

(76 mm 102 mm)

R

outside tank fuel pump above bottom of tank.

Two-Pipe System

Use continuous lengths of heavy wall copper tubing or

steel pipe for oil supply pipe. Install oil supply pipe under

floor or near walls to protect it from damage. Avoid running

pipes along joists or reverberating surfaces. Always use

flare fittings. All fittings must be accessible. Do not use

compression fittings.

IMPORTANT

Both oil supply and return pipes must be submerged

in oil in the supply tank.

Table 5

Two−Pipe Maximum Pipe Length (H + R)

3450 RPM − 3 GPH (11.4 LPH)

Lift H"

3/8" (10 mm) OD

Tubing

1/2" (12 mm) OD

Tubing

Single

Stage

Two

Stage

Single

Stage

Two

Stage

0’

(0.0 m)

84’

(25.6 m)

93’

(28.3 m)

100’

(30.5 m)

100’

(30.5 m)

2’

(0.6 m)

73’

(22.3 m)

85’

(25.9 m)

100’

(30.5 m)

100’

(30.5 m)

4’

(1.2 m)

63’

(19.2 m)

77’

(23.5 m)

100’

(30.5 m)

100’

(30.5 m)

6 ’

(1.8m)

52’

(15.8 m)

69’

(21.0 m)

100’

(30.5 m)

100’

(30.5 m)

8’

(2.4 m)

42’

(12.8 m)

60’

(18.3 m)

100’

(30.5 m)

100’

(30.5 m)

10’

(3.0 m)

31’

(9.4 m)

52’

(15.9 m)

100’

(30.5 m)

100’

(30.5 m)

12’

(3.7 m)

21’

(6.4 m)

44’

(13.4 m)

83’

(25.3 m)

100’

(30.5 m)

14’

(4.3 m)

−−−

36’

(11.0 m)

41’

(12.5 m)

100’

(30.5 m)

16’

(4.9 m)

−−−

27’

(8.2 m)

−−−

100’

(30.5 m)

18’

(5.5 m)

−−−

−−−

−−−

76’

(23.2 m)