Page 5

on carpeting, tile or other combustible material other than

wood flooring. When installed on wood flooring, the addi-

tive base must be used. See Unit Dimension illustration.

Unit must be adjusted to obtain a temperature rise within

the range listed in table 4 in the Adjustments" section.

When used in conjunction with a evaporator coil, the fur-

nace shall be installed in parallel with or on the upstream

side of the evaporator coil. In a parallel flow arrangement,

the dampers or means to control flow of air shall be ade-

quate to prevent chilled air from entering the furnace, and if

manually operated, must be equipped with means to pre-

vent operation of either unit unless dampers are in the full

heat or full cool position.

When installed, furnace must be electrically grounded in

accordance with local codes or, in the absence of local

codes, with the current National Electric Code, ANSI/NFPA

No. 70, if an external electrical source is utilized.

Field wiring connection with unit must meet or exceed

specifications of type T wire and withstand a 63

F (17

C)

temperature rise.

Installation

When installed, OHR23 furnaces must be level. If the fur-

nace is not level, place fireproof wedges or shims between

the low side of the furnace and floor. Make sure the weight

of the furnace is evenly distributed on all four corners.

Strain on sides of the cabinet causing cracking and pop-

ping noises may occur if weight of furnace is not evenly dis-

tributed.

Set the unit in desired location keeping in mind the clear-

ances list in tables 2 and 3. Also keep in mind oil supply

connections, electrical supply, flue connections and suffi-

cient clearance for installing and servicing unit.

OHR23 series units may be installed in a crawl space under

a house, utility room or in a wide variety of suspended ap-

plications.

A−Horizontal Application

The OHR23 furnace is shipped from the factory in the hori-

zontal left hand air discharge application. Air flow may be

reversed to right side discharge or unit may be used as

downflow.

Reversing Airflow for Right Hand Discharge

1− Rotate the furnace 180

so that when facing the front,

the warm discharge is to the right.

2− Remove the nuts in the bracket that hold the burner to

the furnace front. Rotate the burner and burner mount-

ing plate 180

and reinstall the nuts.

3− Remove the screws that hold the limit control in place.

Use the provided knockout hole to relocate the limit

control to the top side of the front panel.

Installation on Non−Combustible Material

Set the furnace on non-combustible material (such as con-

crete blocks, bricks or angle iron). Install spacer legs, pro-

vided with unit, by using the cabinet screws from each cor-

ner of the unit. Use a level to check level of furnace in at

least two directions. Use shims or non-combustible materi-

al. A minimum clearance of 1" must be maintained between

bottom of furnace and combustible material.

Suspended Installation

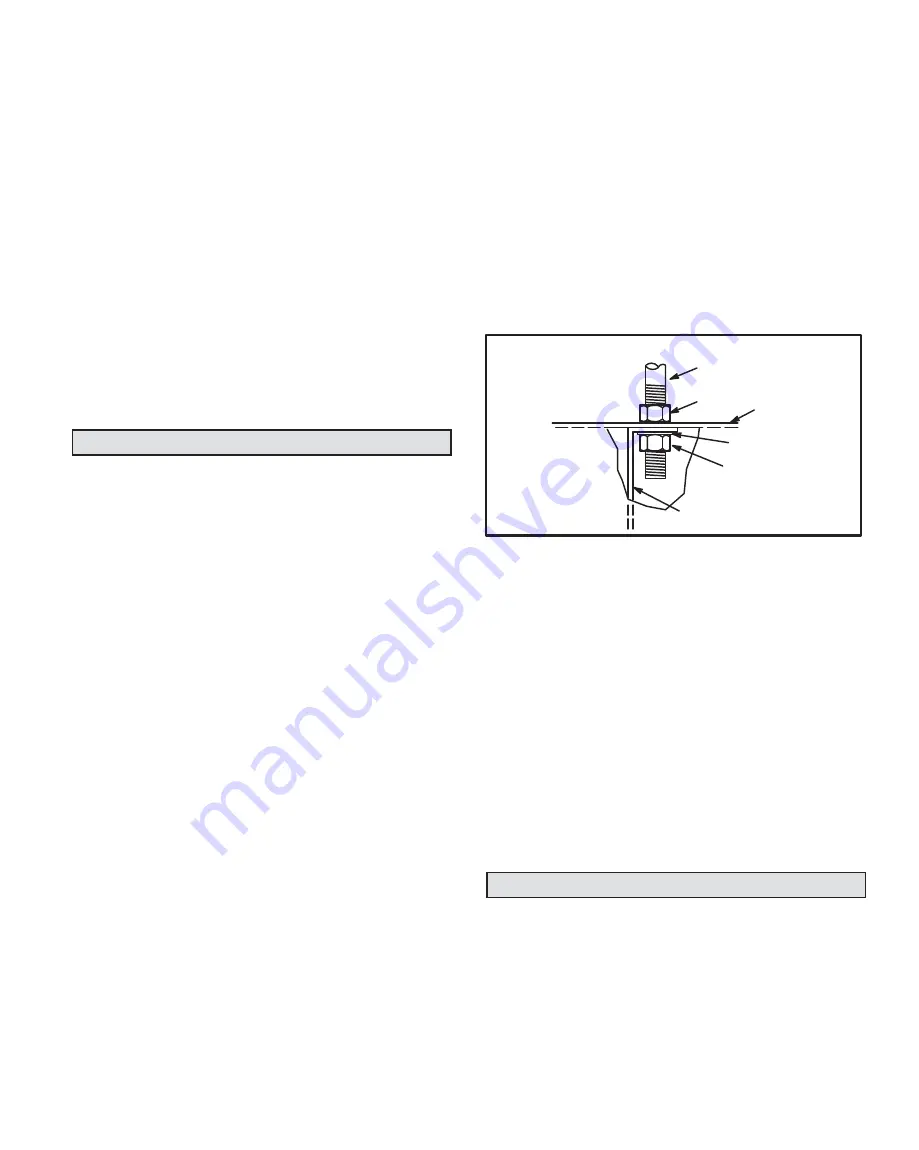

To suspend furnace, remove knockouts in top of panel at

warm air discharge and at blower panel (Refer to unit di-

mensions). Use 3/8" rods cut to desired length. Use one flat

washer and two nuts for each rod. One nut and the washer

on the inside of unit and the other nut on the outside of unit

(the locking nut). Level the unit by adjusting the nuts on the

inside of unit. See figure 3 to suspend unit.

rod

nut

top of

furnace

washer

nut

blower compartment

division panel

Hanger Rod Installation

Figure 3

B−Downflow Application

When installing the OHR23 in a downflow position and on

combustible flooring, a combustible floor base must be

used. See Unit Dimension illustration.

1− Rotate the furnace so that return is on top and supply is

on bottom. Refer to table 3 for clearances to combus-

tible flooring.

2− Remove the nuts in the bracket that hold the burner to

the furnace front. Rotate the burner and burner mount-

ing plate 90

and reinstall the nuts.

3− It is also recommended that the upper rear screw hold-

ing the blower housing to the blower deck be removed

before installation in a closet. Removing this screw al-

lows for easy service and removal of the blower as-

sembly in a closet installation.

Supply & Return Air Plenums

NOTE − The following are suggested procedures that

should be followed when installing the supply and return air

plenums.

1− Use sealing strips of fiberglass.

2− In all cases, the plenum should be secured to furnace

or evaporator cabinet with sheet metal screws.