Page 128 - IOM / ROOF-T

OP

FLEXY™ Series

MAINTENANCE PLAN

TASK

Check HP / LP safety switches

Check outdoor fans and fan guards

Check position of all sensors

Check and clean if necessary all fresh air

grilles

Check indoor and outdoor coils, clean if

necessary

Check electric heater element for excessive

corrosion

Check anti-vibration mountings, for wear and

tear.

Check refrigeration circuit for traces of acid

in the oil

Check Glycol concentration in the HWC

circuit

Check defrost cycle with 4-way valve inver-

sion.

Gas burner module check for corrosion

Sweeping and cleaning the gas burner

Gas supply pressures / connections

checks

Gas regulation valve settings

Check gas burner safety switches

OPERATING MODE

Install manifold gauges on the circuit to be checked. Shut down

the axial fans and wait for the HP switch to shut down the

compressor: 29bar (+1 / -0) auto-reset 22bar (+ - 0.7)

Reconnect fans. Switch off the centrifugal supply fan and wait

for the LP switch to cut out: 0.5bar (+ - 0.5) reset 1.5bar (+-0.5).

Check the fan blades conditions and all fan guards and protec-

tions

Check the good positioning and operation of all sensors of all

sensors. Check the values given in the control system. Replace

sensor if necessary

Check the fresh air grilles (if fitted). If dirty or damaged, remove

them from unit and clean with high pressure water cleaner. Refit

on unit once clean and dry.

Visually check the coils for dirt. If not too dirty, cleaning with a

light brush may be enough (WARNING: Fins and copper tubes

are very fragile! Any damage WILL reduce the performances of

the unit). If very dirty, deep industrial cleaning is required using

de-greasing agents.(External contractors must be called).

Isolate the unit; Pull the electric heater out of the heater module

box and check the resistances fo traces of corrosion; Replace

resistance as required;

Visually check anti-vibration mountings on compressors and

centrifugal fan. Replace if damaged.

Take a sample of oil from the refrigeration circuit.

Check the glycol concentration in the pressurised water circuit.

( a concentration of 30% gives a protection down to aprox. -

15°C) check the circuit pressure

Switch the unit to heat pump mode. Change the set point to

obtain the standard defrost mode and reduce the cycle time to

the min value. Check the operation of the defrost cycle.

Pull out the burner to access the tubes (refer to Gas burner

section in the IOM)

Clean the in-shot burners and the blower wheel lightly with a

brush. Sweep the flue and flue box. Wipe-off the dust from the

housing of the motor. Clean combustion air inlet louvers Pull-out

baffles from the tubes, sweep the tubes

CHECK FLUE BOX GASKET

refer to Gas burner section in the IOM for details

refer to Gas burner section in the IOM for details

refer to Gas burner section in the IOM for details

6

YEARLY

ESTIMATED

MONTHLY QUARTERLY MONTHLY

B4

TIME

WINTER

(mn)

∆

15

0

5

0

5

0

5

0 /

∆

1h if cleaning

0

1h if

replacement

0

1h if

replacement

∆

∆

30

∆

30

∆

30

∆

30

∆

15

∆

30

∆

30

Summary of Contents for ROOFTOP FLEXY FCA 100

Page 1: ...INSTALLATION OPERATING MAINTENANCE MANUAL ROOFTOP FLEXY English August 2003 ...

Page 2: ......

Page 33: ...IOM ROOF TOP FLEXY Series Page 31 AIR FLOW BALANCING AT 12 12 FAN ...

Page 34: ...Page 32 IOM ROOF TOP FLEXY Series AIR FLOW BALANCING AT 15 15 FAN ...

Page 35: ...IOM ROOF TOP FLEXY Series Page 33 AIR FLOW BALANCING AT 18 13 ...

Page 36: ...Page 34 IOM ROOF TOP FLEXY Series AIR FLOW BALANCING AT 18 18 FAN ...

Page 37: ...IOM ROOF TOP FLEXY Series Page 35 AIR FLOW BALANCING RDN 450 FAN ...

Page 38: ...Page 36 IOM ROOF TOP FLEXY Series AIR FLOW BALANCING ADN 355 FAN ...

Page 39: ...IOM ROOF TOP FLEXY Series Page 37 AIR FLOW BALANCING ADN 400 FAN ...

Page 40: ...Page 38 IOM ROOF TOP FLEXY Series AIR FLOW BALANCING ADN 450 FAN ...

Page 104: ...Page 102 IOM ROOF TOP FLEXY Series ELECTRICAL WIRING DIAGRAMS MAIN CURRENT DIAGRAM ...

Page 106: ...Page 104 IOM ROOF TOP FLEXY Series ELECTRICAL WIRING DIAGRAMS CLIMATIC CONTROLLER ...

Page 108: ...Page 106 IOM ROOF TOP FLEXY Series ELECTRICAL WIRING DIAGRAMS CLIMATIC INPUT FG FD ...

Page 112: ...Page 110 IOM ROOF TOP FLEXY Series ELECTRICAL WIRING DIAGRAMS GAS BURNER 180 Kw ...

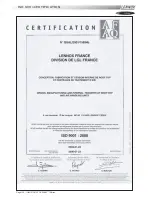

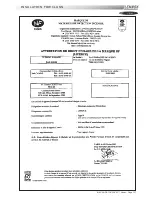

Page 132: ...Page 130 IOM ROOF TOP FLEXY Series ISO 9001 CERTIFICATION ...

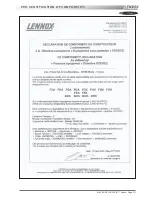

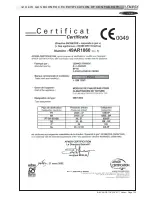

Page 133: ...IOM ROOF TOP FLEXY Series Page 131 PED CERTIFICATION OF CONFORMITY ...

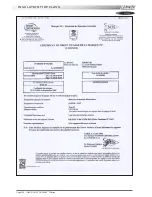

Page 134: ...Page 132 IOM ROOF TOP FLEXY Series GLASS WOOL FIRE CLASS ...

Page 135: ...IOM ROOF TOP FLEXY Series Page 133 33 kW GAS BURNER CE CERTIFICATION OF CONFORMITY ...

Page 136: ...Page 134 IOM ROOF TOP FLEXY Series 60 kW GAS BURNER CE CERTIFICATION OF CONFORMITY ...

Page 137: ...IOM ROOF TOP FLEXY Series Page 135 120 kW GAS BURNER CE CERTIFICATION OF CONFORMITY ...

Page 138: ...Page 136 IOM ROOF TOP FLEXY Series 180 kW GAS BURNER CE CERTIFICATION OF CONFORMITY ...

Page 139: ...IOM ROOF TOP FLEXY Series Page 137 INSULATION FIRE CLASS ...

Page 140: ...Page 138 IOM ROOF TOP FLEXY Series INSULATION FIRE CLASS ...

Page 141: ......