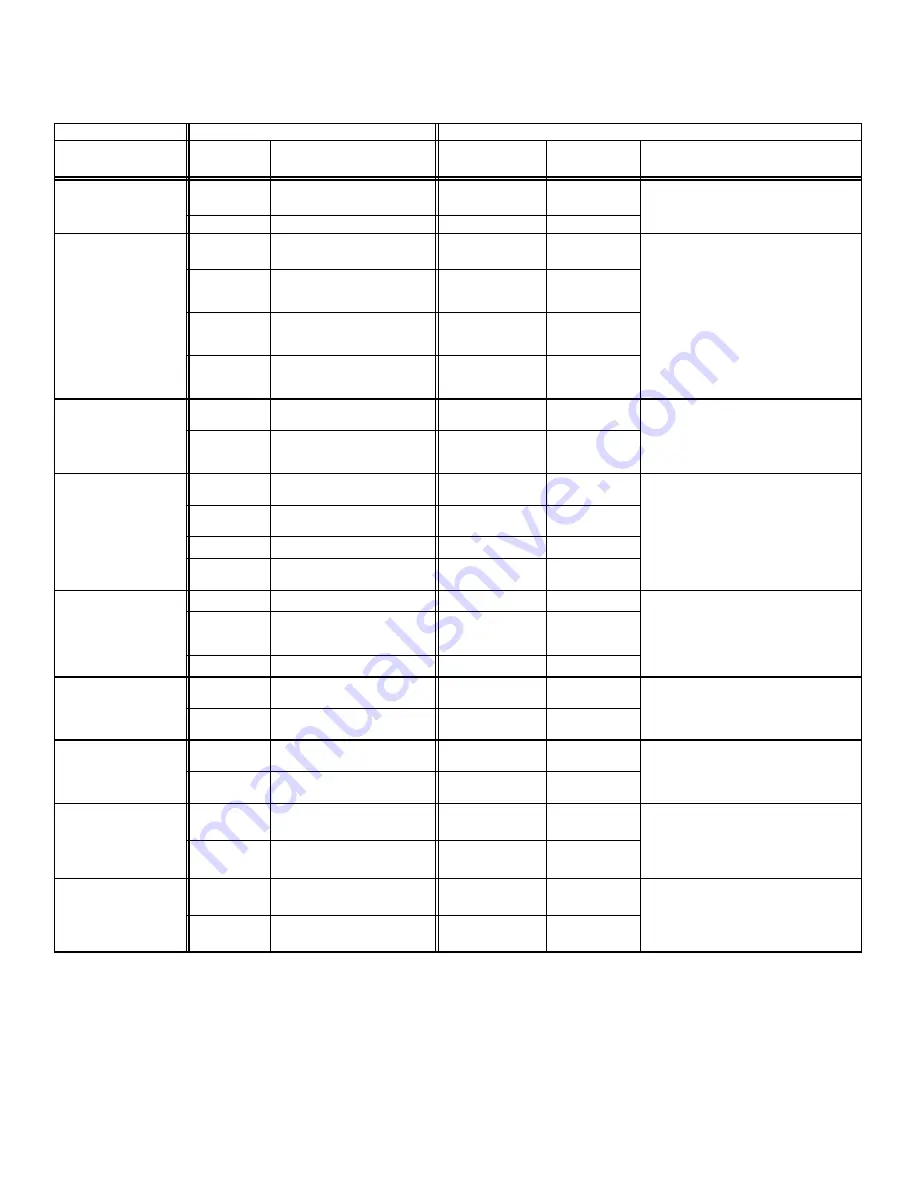

Page 36

TABLE 28

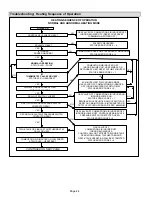

OPERATING SEQUENCE

G60UHV, Thermostat with Humidity Control Feature and Two−Speed Outdoor Unit

OPERATING MODE

SYSTEM DEMAND

SYSTEM RESPONSE

System

Condition

Thermostat

Demand

*Relative Humidity

(Efficiency

Plus

Lights)

****Compressor

Speed

Blower CFM

(COOL)

Comments

Normal operation

Y1

No demand. Acceptable

Low

**42%/46% of

HIGH COOL

Compressor demand and indoor

blower speed controlled by

Normal operation

Y2

No demand. Acceptable

High

HIGH COOL

blower speed controlled by

thermostat demand

Y1

No demand. Acceptable

Low

**42%/46% of

HIGH COOL

Call for humidity

removal during

Y1

Humidity level rises slightly

(1) above setpoint. Demand

initiated.

Low

**42%/46% of

HIGH COOL

Dehumidification mode does not begin

until after initial thermostat demand is

removal during

1st−stage cooling

demand

Demand

satisfied

Humidity level remains

slightly (1) above setpoint.

Demand continues.

Off

Off

until after initial thermostat demand is

satisfied and new cooling demand is

initiated.

Y1

Humidity level remains

slightly (1) above setpoint.

Demand continues.

High

***65%/60% of

HIGH COOL

Significant increase in

humidity during

Y1

No demand. Acceptable

Low

**42%/46% of

HIGH COOL

If humidity rises significantly above set-

point, or if slide switch is moved signifi-

l

i

ill i

di

l

i

d

humidity during

thermostat cooling

demand.

Y1

Humidity level rises signifi-

cantly (2 or more) above

setpoint. Demand initiated.

High

***65%/60% of

HIGH COOL

point, or if slide switch is moved signifi

cantly, unit will immediately go into de-

humidification mode (in presence of

thermostat demand).

Y1

Humidity level

above setpoint.

High

***65%/60% of

HIGH COOL

When humidity demand is satisfied,

Humidity demand

satisfied during

Y1

Humidity level falls below

setpoint. No demand.

High

HIGH COOL

When humidity demand is satisfied,

blower immediately shifts to the COOL

CFM in order to hasten the end of the

cycle Unit can only shift out of high

satisfied during

thermostat demand.

None

No demand. Acceptable

Off

Off

cycle. Unit can only shift out of high

speed compressor operation at begin-

Y1

No demand. Acceptable

Low

**42%/46% of

HIGH COOL

speed compressor operation at begin

ning of next cycle.

Call for humidity

Y2

No demand. Acceptable

High

HIGH COOL

Call for humidity

removal during 2nd

stage thermostat

demand

Y2

Humidity level rises slightly

(1) above setpoint. Demand

initiated.

High

***65%/60% of

HIGH COOL

Blower immediately changes speed in

response to thermostat demand.

demand

Y2

No demand. Acceptable

High

HIGH COOL

*Call for 1st stage

cooling after call for

None

Humidity level is slightly (1)

above setpoint.

Off

Off

Dehumidification mode (high speed

compressor) begins with next thermo-

cooling after call for

humidity removal.

Y1

Humidity level is slightly (1)

above setpoint.

Low

**42%/46% of

HIGH COOL

compressor) begins with next thermo

stat demand after initial demand is sat-

isfied.

Call for 2nd stage

cooling after call for

None

Humidity level is slightly (1)

above setpoint.

Off

Off

Reduced blower speed (dehumidifica-

tion speed) begins immediately with

cooling after call for

humidity removal

Y2

Humidity level is slightly (1)

above setpoint.

High

***65%/60% of

HIGH COOL

tion speed) begins immediately with

thermostat demand

Call for cooling after

significant increase in

None

Humidity level is significantly

above setpoint (2 or more).

Off

Off

If humidity increases significantly over

setpoint, or if slide switch is moved,

unit immediately goes into dehumidifi

significant increase in

humidity

Y1 or Y2

Humidity level is significantly

above setpoint (2 or more).

High

***65%/60% of

HIGH COOL

unit immediately goes into dehumidifi-

cation mode (in presence of thermostat

demand).

Humidity demand

satisfied between

None

Humidity level is slightly (1)

above setpoint.

Off

Off

While unit is not operating (no thermo-

stat demand), slide switch is moved

down and back up Blower and com

satisfied between

thermostat demands

(unit off cycle).

Y1 or Y2

Humidity level falls below

setpoint. No demand.

High

HIGH COOL

down and back up. Blower and com-

pressor operate at high speed until

next thermostat demand.

NOTE − When changing unit mode of operation from cooling to heating, indicating lights that are on will stay on until the first ther-

mostat heating demand.

*IMPORTANT - If power to unit is turned on with thermostat calling for humidity removal, outdoor unit may be locked into high

speed indefinitely. To reset, move humidity slide switch all the way down then back up to desired setpoint (with unit running)

** Reduced blower speed is 42% of HIGH COOL for −36A and −36B units; 46% of HIGH COOL for −60C and −60D series units.

*** Reduced blower speed is 65% of HIGH COOL for −36A and −36B units; 60% of HIGH COOL for −60C and −60D series units.

****If the two−speed control on a two−speed outdoor unit is set for LATCH 2 (15 minutes) or LATCH 3 (30 minutes), the compres-

sor will latch into high speed after a Y1 demand has occurred for that period of time.