Page 10

505331M 06/09

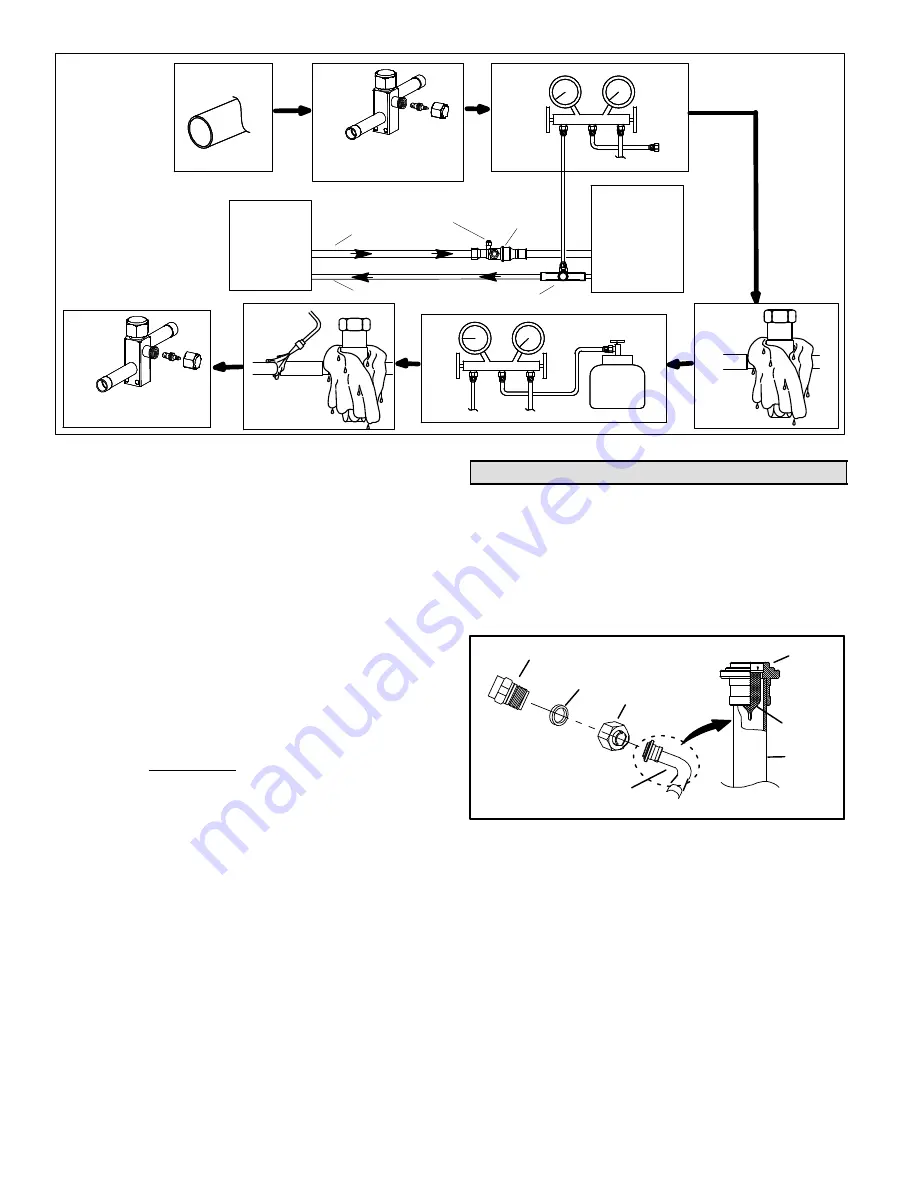

2

3

4

5

6

outdoor

UNIT

LIQUID LINE

SUCTION LINE

SERVICE

VALVE

SERVICE

VALVE

CUT AND DEBUR

ATTACH

GAUGES

WRAP

SERVICE

VALVE

FLOW NITROGEN

NITROGEN

BRAZE LINE SET

1

INSTALL CORE ONLY FOR

BOTH SERVICE PORTS after they

have coolED.

7

INDOOR UNIT

REMOVE CAP AND CORE FROM

BOTH LIQUID AND SUCTION

SERVICE PORTS

SERVICE PORT MUST BE

OPEN TO ALLOW EXIT

POINT FOR NITROGEN

Figure 19. Brazing Connections

2. Remove service cap and core from both the suction

and liquid line service ports.

3. Connect gauge low pressure side to liquid line service

valve.

4. To protect components during brazing, wrap a wet

cloth around the liquid line service valve body and

copper tube stub and use another wet cloth

underneath the valve body to protect the base paint.

Also, shield the light maroon R−410A sticker.

5. Flow regulated nitrogen (at 1 to 2 psig) through the

refrigeration gauge set into the valve stem port

connection on the liquid line service valve and out of

the valve stem port connection on the suction service

valve.

NOTE The RFCIV or TXV metering device at the indoor

unit will allow low pressure nitrogen to flow through the

system.)

6. Braze the liquid line to the liquid line service valve.

Turn off nitrogen flow. Repeat procedure starting at

paragraph 4 for brazing the suction line to the suction

service valve.

7. After all connections have been brazed, disconnect

manifold gauge set the from service ports, cool down

piping with wet rag and remove all wrappings. Do not

reinstall cores until after evacuation procedures.

Reinstall service caps if desired to close off refrigerant

ports.

Removing Indoor Unit Metering Device11

Remove the existing HCFC−22 refrigerant flow control

orifice or thermal expansion valve from the indoor coil. The

existing indoor unit HCFC−22 metering device is not

approved for use with HFC−410A refrigerant and may

prevent proper flushing.

REPLACEMENT PARTS

If replacement parts are necessary for the indoor unit,

order kit 69J46. The kit includes:

TEFLON RINGS (20)

BRASS NUTS (10)

LIQUID LINE ASSEMBLIES

(INCLUDES STRAINER) (10)

LIQUID LINE ORIFICE HOUSINGS (10)

LIQUID LINE

ASSEMBLY

COPPER

TUBE

PISTON

RETAINER

STRAINER

Figure 20. 69J46 Kit Components

TYPICAL FIXED ORIFICE REMOVAL PROCEDURE

1. On fully cased coils, remove the coil access and

plumbing panels.

2. Remove any shipping clamps holding the liquid line

and distributor assembly.

3. Using two wrenches, disconnect liquid line from liquid

line orifice housing. Take care not to twist or damage

distributor tubes during this process.