Page 15

XP19 SERIES

cylinder with pressure regulator set to 150 psig (1034

kPa) and purge the hose. Open the manifold gauge

valves to break the vacuum in the line set and indoor

unit. Close the manifold gauge valves.

7. Shut off the dry nitrogen cylinder and remove the

manifold gauge hose from the cylinder. Open the

manifold gauge valves to release the dry nitrogen from

the line set and indoor unit.

8. Reconnect the manifold gauge to the vacuum pump,

turn the pump on, and continue to evacuate the line set

and indoor unit until the absolute pressure does not

rise above 500 microns (29.9 inches of mercury) within

a 20−minute period after shutting off the vacuum pump

and closing the manifold gauge valves.

9. When the absolute pressure requirement above has

been met, disconnect the manifold hose from the

vacuum pump and connect it to an upright cylinder of

HFC−410A refrigerant. Open the manifold gauge valve

1 to 2 psig in order to release the vacuum in the line set

and indoor unit.

10. Perform the following:

A

Close manifold gauge valves.

B

Shut off HFC−410A cylinder.

C

Reinstall service valve cores by removing

manifold hose form service valve. Quickly install

core with core tool while maintaining a positive

system pressure.

D

Replace the stem caps and secure finger tight,

then tighten an additional one−sixth (1/6) of a turn

as illustrated in Figure 2.

Servicing Units Delivered Void of

Charge16

If the outdoor unit is void of refrigerant, clean the system

using the procedure described below.

1. Use nitrogen to pressurize the system and check for

leaks. Repair all leaks.

2. Evacuate the system to remove as much of the

moisture as possible.

3. Use nitrogen to break the vacuum and install a new

filter drier in the system.

4. Evacuate the system again. Then, weigh the

appropriate amount of HFC−410A refrigerant as listed

on unit nameplate into the system.

5. Monitor the system to determine the amount of

moisture remaining in the oil. It may be necessary to

replace the filter drier several times to achieve the

required dryness level.

If system dryness is not

verified, the compressor will fail in the future.

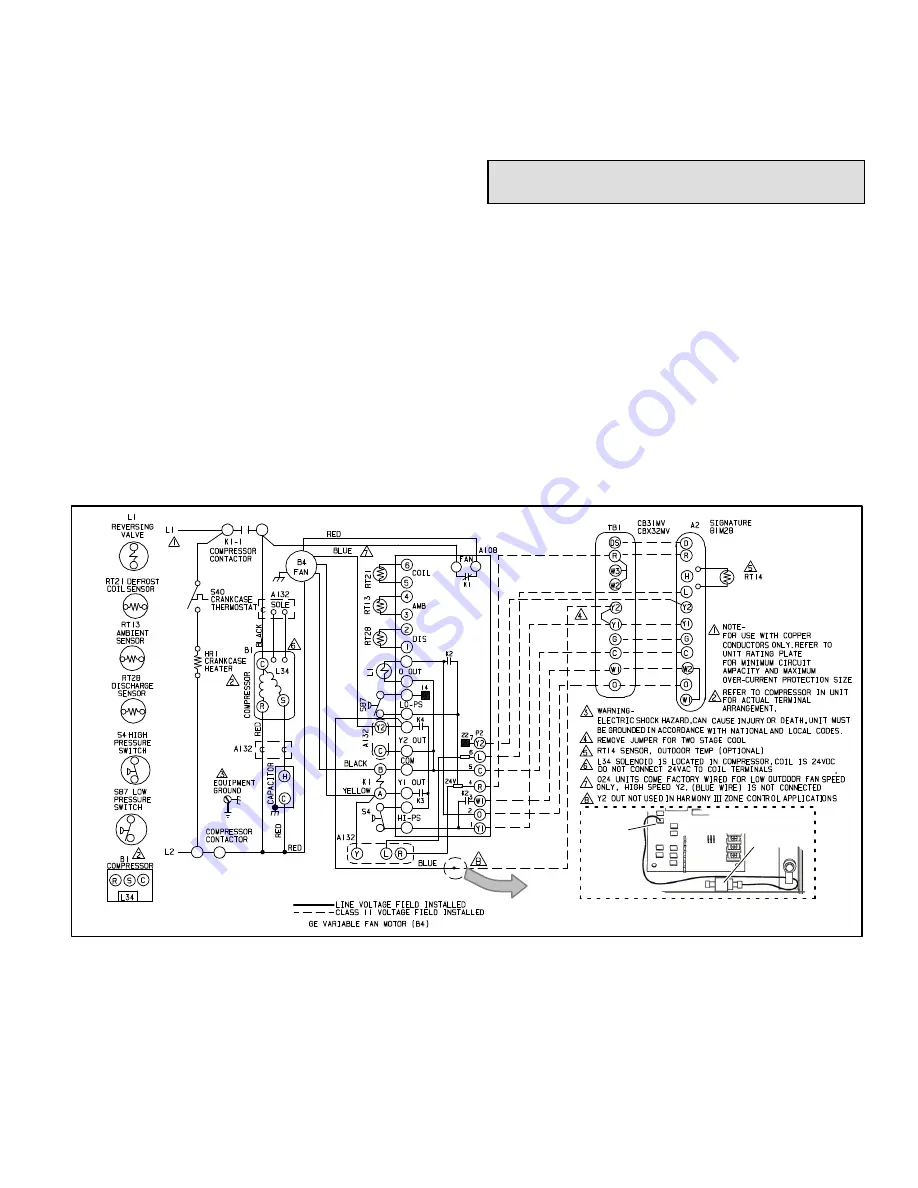

SHIPPED AS SHOWN ABOVE WITH TERMINAL CRIMPED TO BLUE

WIRE; USE TERMINAL OR CUT OFF TERMINAL AND SPLICE BLUE

WIRE WITH Y2 WIRE TO INDOOR UNIT.

BLUE WIRE

WITH CRIMPED

TERMINAL

DEFROST

BOARD

DETAIL

Y2 OUT

Figure 29. XP19 Wiring