Page 20

505331M 06/09

Table 8. Normal Operating Pressure − 10 and Vapor

+5 PSIG*

IMPORTANT

Minor variations in these pressures may be

expected due to differences in installations.

Significant differences could mean that the system

is not properly charged or that a problem exists with

some component in the system.

5

F (

5

C)**

XP19−024

XP19−036

XP19−048

XP19−060

Liq

Vap

Liq

Vap

Liq

Vap

Liq

Vap

First Stage (Low Capacity)

40 (4.4)

314

100

316

99

350

98

365

96

50 (10)

334

120

334

117

367

111

388

112

Second Stage (High Capacity)

20 (−7.0)

304

68

294

64

314

60

346

60

30 (−1.0)

323

82

313

77

331

72

362

72

40 (4.4)

342

98

329

89

358

85

382

85

50 (10)

364

116

344

109

384

107

409

106

First Stage (Low Capacity)

65 (18.3)

226

152

230

148

210

136

234

135

75 (23.9)

262

151

267

150

242

138

274

137

85 (29.4)

304

152

309

153

286

140

314

142

95 (35.0)

351

155

355

155

328

142

361

147

105 (40.6)

400

158

404

157

374

144

413

147

115 (49.0)

454

161

460

159

426

146

470

149

Second Stage (High Capacity)

65 (18.3)

228

146

236

144

227

114

237

131

75 (23.9)

267

148

275

145

265

123

276

133

85 (29.4)

309

149

318

148

306

132

320

135

95 (35.0)

358

151

365

150

348

138

369

138

105 (40.6)

410

152

416

153

397

141

423

140

115 (49.0)

465

154

473

155

453

143

482

144

*These are most−popular−match−up pressures. Indoor match up,

indoor air quality, and indoor load cause pressures to vary.

**Temperature of the air entering the outside coil.

Table 9

.

HFC−410A Temperature (°F) − Pressure (Psig)

°F

Psig

°F

Psig

°F

Psig

°F

Psig

32

100.8

63

178.5

94

290.8

125

445.9

33

102.9

64

181.6

95

295.1

126

451.8

34

105.0

65

184.3

96

299.4

127

457.6

35

107.1

66

187.7

97

303.8

128

463.5

36

109.2

67

190.9

98

308.2

129

469.5

37

111.4

68

194.1

99

312.7

130

475.6

38

113.6

69

197.3

100

317.2

131

481.6

39

115.8

70

200.6

101

321.8

132

487.8

40

118.0

71

203.9

102

326.4

133

494.0

41

120.3

72

207.2

103

331.0

134

500.2

42

122.6

73

210.6

104

335.7

135

506.5

43

125.0

74

214.0

105

340.5

136

512.9

44

127.3

75

217.4

106

345.3

137

519.3

45

129.7

76

220.9

107

350.1

138

525.8

46

132.2

77

224.4

108

355.0

139

532.4

47

134.6

78

228.0

109

360.0

140

539.0

48

137.1

79

231.6

110

365.0

141

545.6

49

139.6

80

235.3

111

370.0

142

552.3

50

142.2

81

239.0

112

375.1

143

559.1

51

144.8

82

242.7

113

380.2

144

565.9

52

147.4

83

246.5

114

385.4

145

572.8

53

150.1

84

250.3

115

390.7

146

579.8

54

152.8

85

254.1

116

396.0

147

586.8

55

155.5

86

258.0

117

401.3

148

593.8

56

158.2

87

262.0

118

406.7

149

601.0

57

161.0

88

266.0

119

412.2

150

608.1

58

163.9

89

270.0

120

417.7

151

615.4

59

166.7

90

274.1

121

423.2

152

622.7

60

169.6

91

278.2

122

428.8

153

630.1

61

172.6

92

282.3

123

434.5

154

637.5

62

175.4

93

286.5

124

440.2

155

645.0

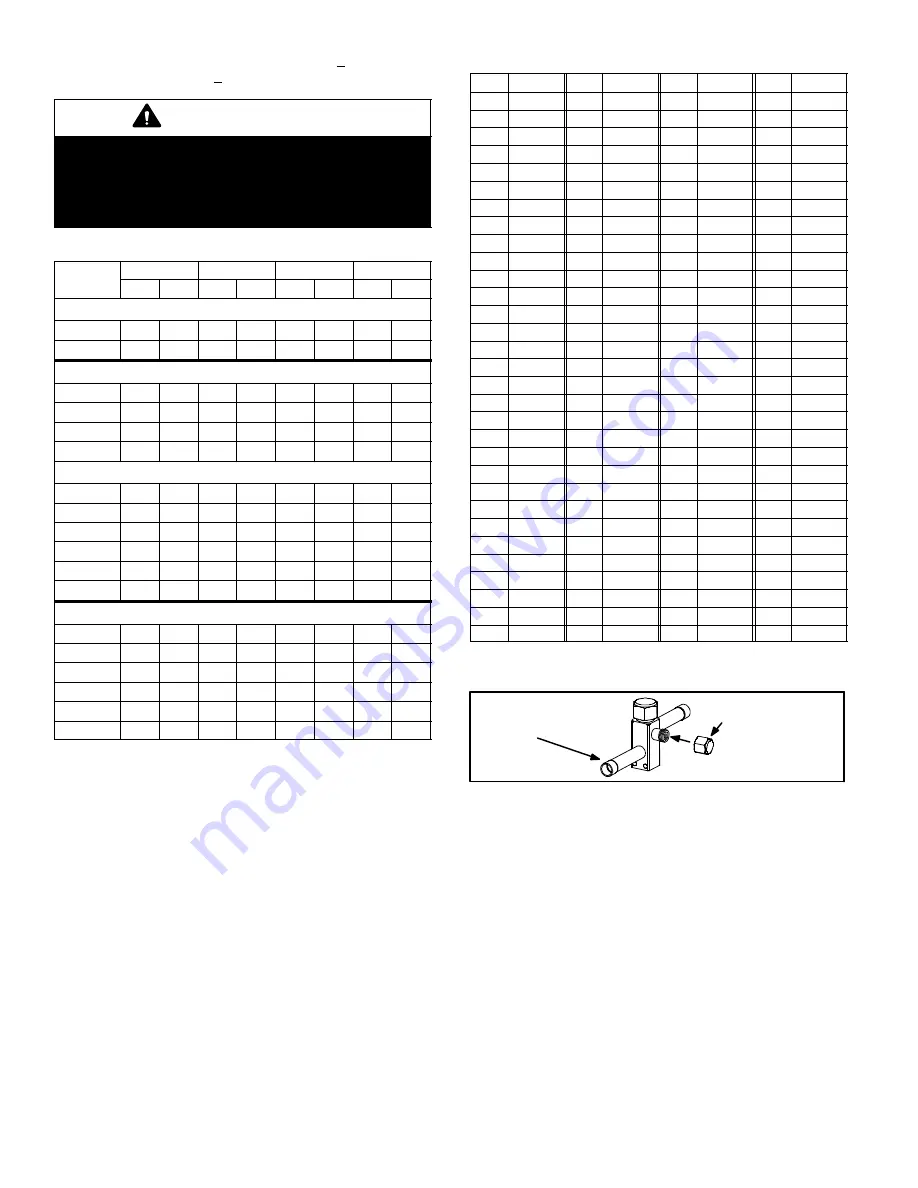

INSTALLING SERVICE VALVE CAPS

Disconnect gauge set and re−install all service valve caps.

INSTALL CAPS

OUTDOOR UNIT

SERVICE VALVE

Figure 33. Installing Service Valve Port Caps