Page 24

505331M 06/09

Defrost System21

DEFROST SYSTEM DESCRIPTION

The defrost control board (DCB) measures differential

temperatures to detect when the system is performing

poorly because of ice build−up on the outdoor coil. The

controller self−calibrates when the defrost system starts

and after each system defrost cycle. The DCB

components are illustrated on page 22.

The DCB monitors ambient temperature, outdoor coil

temperature, and total run time to determine when a

defrost cycle is required. The coil temperature probe is

designed with a spring clip to allow mounting to the outside

coil tubing. The location of the coil sensor is important for

proper defrost operation.

NOTE The DCB accurately measures the performance

of the system as frost accumulates on the outdoor coil.

This typically will translate into longer running time

between defrost cycles as more frost accumulates on the

outdoor coil before the board initiates defrost cycles.

DIAGNOSTIC LEDS

The state (Off, On, Flashing) of two LEDs on the DCB

(DS1 [Red] and DS2 [Green]) indicate diagnostics

conditions that are described in Table 15.

DCB PRESSURE SWITCH CONNECTIONS

The unit’s automatic reset pressure switches (LO PS − S87

and HI PS − S4) are factory−wired into the DCB on the

LO−PS and HI−PS terminals, respectively.

Low Pressure Switch (LO−PS)

When the low pressure

switch trips, the DCB will cycle off the compressor, and the

strike counter in the board will count one strike. The low

pressure switch is ignored under the following conditions:

S

during the defrost cycle and 90 seconds after the

termination of defrost

S

when the average ambient sensor temperature is

below 15° F (−9°C)

S

for 90 seconds following the start up of the compressor

S

during TEST mode

High Pressure Switch (HI−PS)

When the high pressure

switch trips, the DCB will cycle off the compressor, and the

strike counter in the board will count one strike.

DCB PRESSURE SWITCH EVENT SETTINGS

The following pressures are the auto reset event values for

low and high pressure thresholds:

High Pressure

(auto reset) − trip at 590 psig; reset at 418.

Low Pressure

(auto reset) − trip at 25 psig; reset at 40.

FIVE−STRIKE LOCKOUT SAFETY FUNCTION

The five−strike lockout safety function is designed to

protect the unit’s compressor from damage. The DCB

looks for 24VAC on it’s Y1 terminal. When the Y1 input is

see 24VAC, then internal control logic of the DCB will do

the following:

S

Count any HI−PS and LO−PS pressure switch trips

(open and close). Individual HI−PS and LO−PS trips

are added together for the total number of trips

counted by the DCB.

S

Up to four pressure switch trips are allowed in a single

thermostat demand without locking out the DCB. If the

thermostat demand satisfies before a fifth pressure

switch trip, the DCB will reset the five−strike counter to

zero.

S

If either pressure switch opens for a fifth time during

the current Y1 input state, the DCB will enter a lockout

condition.

The system will require servicing to determine the cause of

the pressure switch condition. Once the condition has

been rectified, use the following procedure to reset the

DCB

.

Low Ambient Thermostat Pins

− P3 provides selecting of

the Y2 compressor lock−in temperature.

DEFROST SYSTEM SENSORS

Sensors connect to the DCB through a field-replaceable

harness assembly that plugs into the board. Through the

sensors, the DCB detects outdoor ambient, coil, and

discharge temperature fault conditions. As the detected

temperature changes, the resistance across the sensor

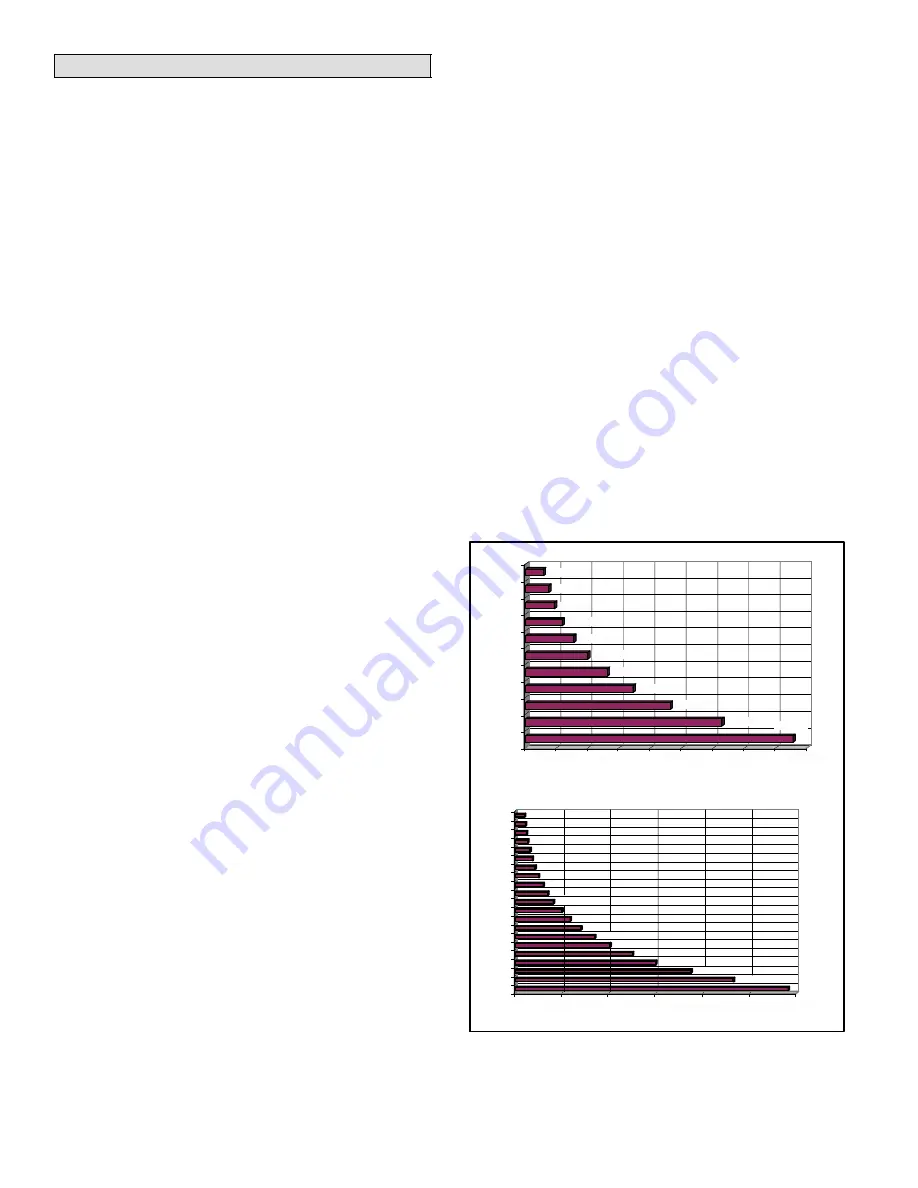

changes. Figure 34 shows how the resistance varies as

the temperature changes for both type of sensors. Sensor

resistance values can be checked by ohming across pins

shown in Table 34.

Ambient and Coil Sensor

Discharge Sensor

RESISTANCE (OHMS)

RESISTANCE (OHMS)

TEMPERA

TURE (ºF)

TEMPERA

TURE (ºF)

5750

7450

9275

11775

15425

19975

26200

34375

46275

62700

200

325

250

425

600

825

1175

1700

2500

3750

5825

100

90

80

70

60

50

40

30

20

10

0

300

280

260

240

220

200

180

160

140

120

100

10000

30000

50000

70000

90000

1000

2000

5000

4000

6000

3000

4650

3000

2025

1400

1000

700

225

275

375

500

85300

Figure 34. Temperature/Resistance Chart