Page 25

XP19 SERIES

Table 13. Sensor Temperature / Resistance Range

Sensor

Temperature

Range °F (°C)

Resistance values

range (ohms)

Pins/Wire

Color

Outdoor

(Ambient)

−35 (−37) to 120

(48)

280,000 to 3750

3 and 4

(Black)

Coil

−35 (−37) to 120

(48)

280,000 to 3750

5 and 6

(Brown)

Discharge (if

applicable)

24 (−4) to 350

(176)

41,000 to 103

1 and 2

(Yellow)

NOTE

Sensor resistance decreases as sensed temperature

increases (see Figure 34).

NOTE When checking the ohms across a sensor, be

aware that a sensor showing a resistance value that is not

within the range shown in Table 13, may be performing as

designed. However, if a shorted or open circuit is detected,

then the sensor may be faulty and the sensor harness will

need to be replaced.

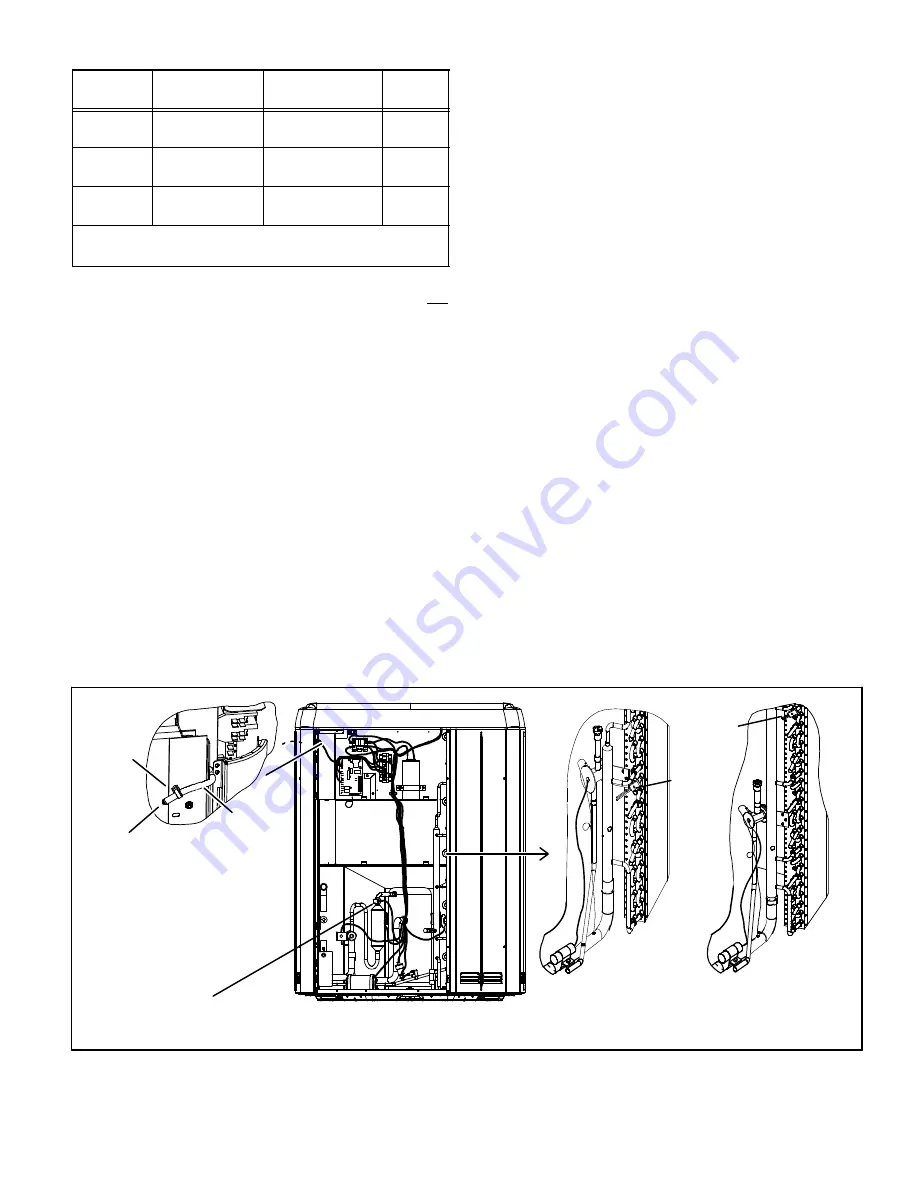

Defrost Coil Sensor (RT21)

This sensor (shown in

Figure 35, Detail A) considers outdoor temperatures below

−35°F (−37°C) or above 120°F (48°C) as a fault. If the

defrost coil sensor is detected as being open, shorted or

out of the temperature range of the sensor, the board will

not perform demand or time/temperature defrost

operation and will display the appropriate fault code.

Heating and cooling operation will be allowed in this fault

condition.

Discharge Line Sensor (RT28)

If this sensor exceeds

a temperature of 300°F (148°C) during compressor

operation, the board will de−energize the compressor

contactor output (and the defrost output, if active). The

compressor will remain off until the discharge temperature

has dropped below 225°F (107°C) and the 5-minute

anti−short cycle delay has been satisfied. This sensor has

two fault and lockout codes:

1. If the board recognizes five high discharge line

temperature faults during a single (Y1) compressor

demand, it reverts to a lockout mode and displays the

appropriate code. This code detects shorted sensor or

high discharge temperatures. Code on board is

Discharge Line Temperature Fault and Lockout

.

2. If the board recognizes five temperature sensor range

faults during a single (Y1) compressor demand, it

reverts to a lockout mode and displays the appropriate

code. The board detects open sensor or

out-of-temperature sensor range. This fault is

detected by allowing the unit to run for 90 seconds

before checking sensor resistance. If the sensor

resistance is not within range after 90 seconds, the

board will count one fault. After five faults, the board

will lockout. Code on board is

Discharge Sensor Fault

and Lockout

.

The discharge line sensor (see Figure 35), which covers a

range of 150°F (65°C) to 350°F (176°C), is designed to

mount on a

½

" refrigerant discharge line.

Ambient Sensor (RT13)

The ambient sensor (shown

in Figure 35, Detail B) considers outdoor temperatures

below −35°F (−37°C) or above 120°F (48°C) as a fault. If the

ambient sensor is detected as being open, shorted or out

of the temperature range of the sensor, the board will not

perform demand defrost operation. The board will revert to

time/temperature defrost operation and will display the

appropriate fault code. Heating and cooling operation will

be allowed in this fault condition.

NOTE Within a single room thermostat demand, if

5−strikes occur, the board will lockout the unit. DCB 24 volt

power

R

must be cycled OFF or the TEST pins on board

must be shorted between 1 to 2 seconds to reset the

board.

24 TUBES

UP

SLEEVE

AMBIENT SENSOR

− EXTEND TIP OF

PLASTIC SENSOR JUST OUTSIDE OF PLASTIC

SLEEVE.

PLACE AMBIENT SENSOR AND WIRE FROM

DCB INSIDE OF PLASTIC SLEEVE AND ROUTE

THROUGH GAP BETWEEN CORNER POST AND

COIL SUPPORT AS SHOWN. SECURE WITH

WIRE TIE.

WIRE TIE

MODELS −024 AND −036

MODELS −048 AND −060

12 TUBES

UP

COIL SENSOR

− CLIP COIL TEMPERATURE SENSOR FROM THE DCB ON THE RETURN BEND

SHOWN ON MODELS AS FOLLOWS:

DETAIL A

DETAIL B

DISCHARGE LINE

SENSOR

Figure 35. Sensor Locations