Page 5

XP19 SERIES

3. Remove all HCFC−22 refrigerant from the existing

system. Check gauges after shutdown to confirm that

the entire system is completely void of refrigerant.

MANIFOLD GAUGES

RECOVERY MACHINE

CLEAN RECOVERY

CYLINDER

OUTDOOR UNIT

Figure 7. Typical Refrigerant Recovery

(Method 1)

NOTE Use recovery machine instructions for specific

setup requirements.

METHOD 2:

Use this method if the existing outdoor unit is equipped

with manual shut−off valves, and plan on using new

HCFC−22

refrigerant to flush the system.

IMPORTANT

: Some system configurations may contain

higher than normal refrigerant charge due to either large

internal coil volumes, and/or long line sets. The following

conditions may cause the compressor to stop functioning:

The following devices could prevent full system charge

recovery into the outdoor unit:

S

Outdoor unit’s high or low−pressure switches (if

applicable) when tripped can cycled the compressor

OFF

.

S

Compressor can stop pumping due to tripped internal

pressure relief valve.

S

Compressor has internal vacuum protection that is

designed to unload the scrolls (compressor stops

pumping) when the pressure ratio meets a certain

value or when the suction pressure is as high as 20

psig. (Compressor suction pressures should never be

allowed to go into a vacuum. Prolonged operation at

low suction pressures will result in overheating of the

scrolls and permanent damage to the scroll tips, drive

bearings and internal seals).

Once the compressor can not pump down to a lower

pressure due to one of the above system conditions, shut

off the suction valve. Turn OFF the main power to unit and

use a recovery machine to recover any refrigerant left in

the indoor coil and line set.

Perform the following task:

1. Start the existing HCFC−22 system in the cooling

mode and close the liquid line valve.

2. Pump as much of the existing HCFC−22 refrigerant

with the compressor back into the outdoor unit until

you have reached the limitations of the outdoor

system. Turn the outdoor unit main power

OFF

and

use a recovery machine to remove the remaining

refrigerant in the system.

NOTE It may be necessary to bypass the low pressure

switches if equipped to ensure complete refrigerant

evacuation.

3. When the low side system pressures reach 0 psig,

close the suction line valve.

4. Check gauges after shutdown to confirm that the

valves are not allowing refrigerant to flow back into the

low side of the system.

Removing Existing Outdoor Unit6

Perform the following task at the existing outdoor unit:

S

Disconnect line set at the service valves.

S

Disconnect electrical service at the disconnect switch.

S

Remove old outdoor unit.

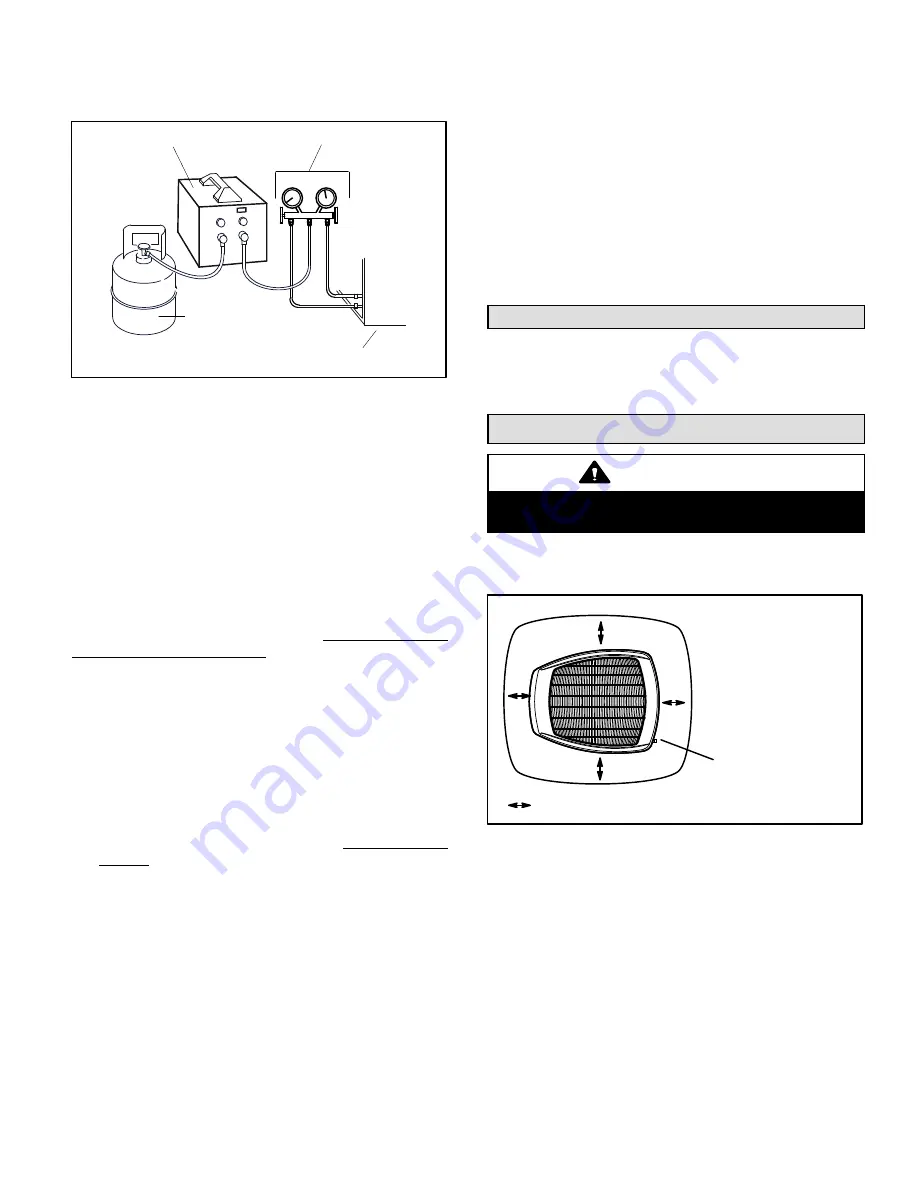

Positioning New Outdoor Unit7

CAUTION

In order to avoid injury, take proper precaution when

lifting heavy objects.

See

Unit Dimensions

on page 3 for sizing mounting slab,

platforms or supports. Refer to Figure 8 for mandatory

installation clearance requirements.

SEE NOTES BELOW THIS FIGURE FOR FURTHER DETAILS.

CONTROL PANEL

ACCESS LOCATION

Figure 8. Installation Clearances

NOTES:

S

Service clearance of 30 in. (762 mm) must be

maintained on one of the sides adjacent to the control

box.

S

Clearance to one of the other three sides must be 36

in. (914 mm)

.

S

Clearance to one of the remaining two sides may be

12 in. (305 mm) and the final side may be 6 in. (152

mm)

.

S

48 in. (1219 mm) clearance required on top of unit.

S

A clearance of 24 in. (610 mm) must be maintained

between two units.