13

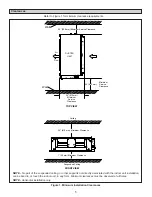

Model

Condensate

Life Pump

Factory

Mounted

Condensate

Pump Lift

Measurement

Condensate Pump

Facility on Indoor

PCB Board

Condensate

Outlet of

Indoor Unit

Flexible Drain Con

nection (supplied

with unit)

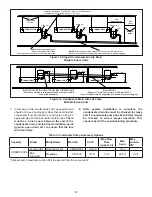

VOSB Outside Air

Ducted

Yes - 036-054

No - 072/096

18 “

Yes

1” O.D.

1-5/8” O.D.

adapter pro-

vided

1” I.D.

Table 4. Condensate Connection Sizes

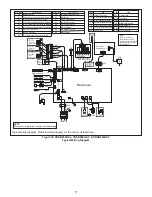

Wiring Connections

In the U.S.A., wiring must conform with current local

codes and the current National Electric Code (NEC). In

Canada, wiring must conform with current local codes and

the current Canadian Electrical Code (CEC).

Refer to unit nameplate for minimum circuit ampacity and

maximum overcurrent protection size.

NOTE -

Two-conductor stranded shielded cable must be

used for the communication wiring. This is necessary to

ensure proper system communication and operation.

• Indoor and outdoor unit equipment must each be on

their own a dedicated breaker.

• Indoor units must have a dedicated service disconnect.

Switches are acceptable; however it must be a double

pole switch that disconnects L1 and L2.

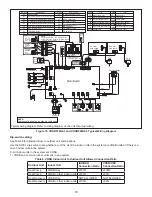

WARNING

Isolate the power supply before accessing unit electrical

terminals.

Install unit so that unit disconnect is accessible.

Follow all local and national codes, as well as this

installation instruction, during installation. Do NOT

overload electrical circuit, as this may lead to failure and

possible fire.

Use specified wiring and cable to make electrical

connections. Clamp cables securely and make sure that

connections are tight to avoid strain on wiring. Insecure

wiring connections may result in equipment failure and

risk of fire.

Wiring must be installed so that all cover plates can be

securely closed.

Do not attempt to repair a damaged power cord.

Do not modify the power cord in any way. Do not

attempt to extend the length of the power cord or use

an extension cord with this appliance. Do not share the

single power outlet with any other appliances.

CAUTION

This unit must be properly grounded and protected by a

circuit breaker. The ground wire for the unit must not be

connected to a gas or water pipe, a lightning conductor

or a telephone ground wire.

Do not connect power wires to the outdoor unit until

all other wiring and piping connections have been

completed.

Install all wiring at least 3 feet away from televisions,

radios or other electronic devices in order to avoid the

possibility of interference with the unit operation.

Do not install the unit near a lighting appliance that

includes a ballast. The ballast may affect remote control

operation.

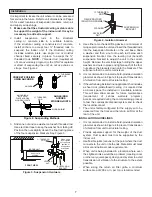

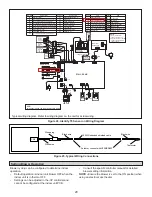

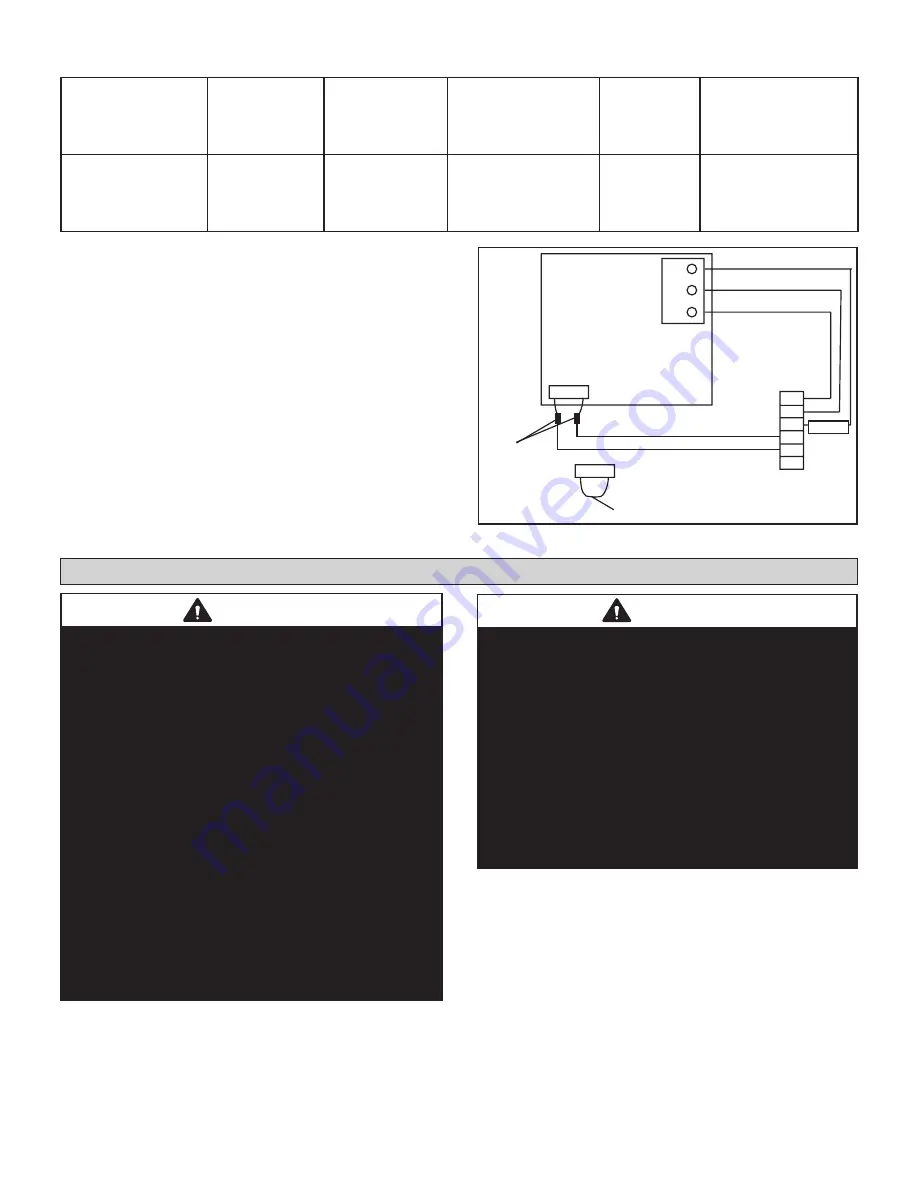

Using an External Water Level Switch

1. Disconnect the closed circuit loop connection

labeled WATER.

2.

Connect the provided overflow harness accessory to

the WATER connection. See Figure 14.

3. See unit wiring diagrams for location of the WATER

connection.

The connection has 5 VDC current, do not supply field

voltage.

Table 3 lists available external condensate pump

accessories. See Table 4 for connection sizes.

G

L2

L1

NC

COM

NO

PUMP

CONNECTIONS

0.5A

G

L1

L2

GREEN

OPTIMAL

Cut wire here

INDOOR

UNIT

MAIN

BOARD

Connect to

pump here

using solder

or butt joints

WATER

WATER

Figure 14. External Water Level Switch Connection