Page 34

506518−01

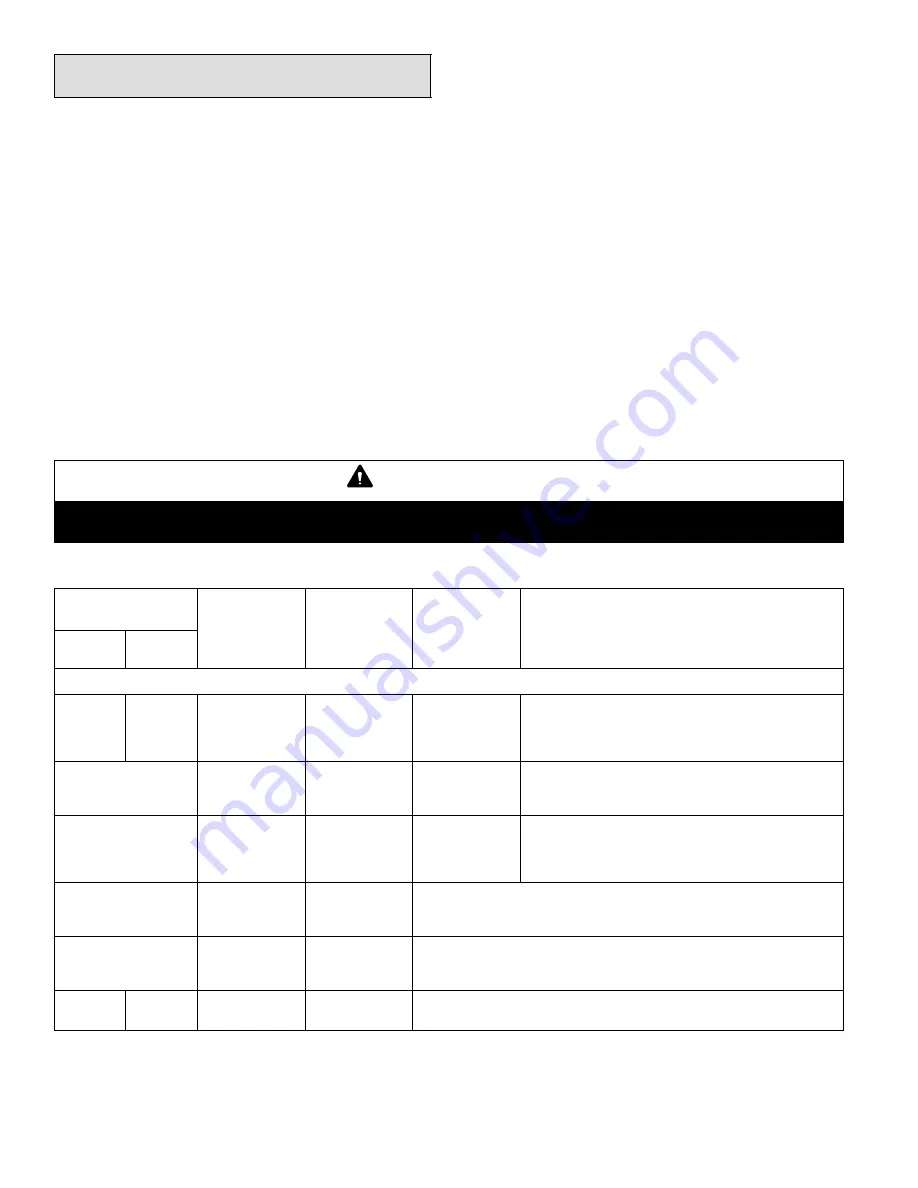

A175 Main Control LED System Status

and Alert and Codes

LED alert codes are display using various LEDs located on

the A175 Main Control.

DS11 AND DS14 LED SYSTEM AND ALERT CODES

DS11 (Green) and DS14 (Red) LEDs indicate

non−communicating mode diagnostics conditions that are

listed in table 9.

These LEDs display fault conditions in system cooling

capacity, dehumidification mode, anti−short cycle lockout,

high and low pressures, discharge line temperature,

outdoor temperature, and discharge sensor failures.

DS15 AND DS13 LED COMPRESSOR ALERT CODES

DS15 (Yellow) and DS13 (Red) LEDs indicate

non−communicating mode diagnostics conditions that are

listed in table 10.

These LEDs display the most common fault conditions in

the system. When an abnormal condition is detected, this

function communicates the specific condition through

system diagnostic LEDs. The function is capable of

detecting both mechanical and electrical system

problems.

RESETTING LED ALERT CODES

LED alert codes can be reset manually or automatically:

1.

Manual Reset

Manual reset can be achieve by one of the following

methods:

S

Disconnecting

R

wire from the A175 main

control’s

R

terminal.

S

Turning the indoor unit off an on again.

Cycle the 24VAC power to A175 main control off and

on. After power up, existing code will display for 60

seconds and then clear.

2.

Automatic Reset

After an alert is detected, the A175 main control

continues to monitor the unit’s system and

compressor operations. When/if conditions return to

normal, the alert code is turned off automatically.

IMPORTANT

LED alert codes do not provide safety protection. The is a monitoring function only and cannot control or shut down other

devices

.

Table 9. System Alert Codes (A175 Main Control LEDs and Communicating Thermostat User Interface)

Outdoor A175 Main

Control LEDs

icomfort

Touch

t

Thermostat

Display

Condition

Possible

Cause(s)

Solution

DS11

Green

DS14 Red

SYSTEM STATUS

OFF

OFF

Not Applicable

Power problem

No power (24V)

to control

terminals R and C

or control failure.

1

Check control transformer power (24V).

2

If power is available to control and LED(s) do not light,

replace control.

Simultaneous SLOW

Flash

Not Applicable

Normal operation

Unit operating

normally or in

standby mode.

Indicates that control has internal component failure. Cycle

24 volt power to control. If code does not clear, replace

control.

Alternating SLOW

Flash

Not Applicable

5−minute

anti−short cycle

delay

Initial power up,

safety trip, end of

room thermostat

demand.

None required (Jumper FIELD TEST pins to override)

Simultaneous FAST

Flash

Moderate /

Critical Alert

Code 180

Ambient Sensor

Problem

Sensor being detected open or shorted or out of temperature range. control will

revert to time/temperature defrost operation. (System will still heat or cool).

Alternating FAST Flash

Moderate /

Critical Alert

Code 417

Coil Sensor

Problem

This model does not utilize a coil sensor, however this alert indicates either an

open or shorted circuit. See if 10K resistor is not damage or missing. Resistor is

located in the sensor harness assembly, brown lead.

ON

ON

Not Applicable

A175 Main

Control Failure

Indicates that control has internal component failure. Cycle 24 volt power to

control. If code does not clear, replace control.

Summary of Contents for XC21

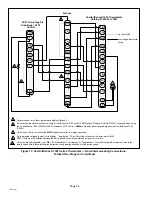

Page 21: ...Page 21 XC21 SERIES Figure 8 Typical XC21 Wiring ...

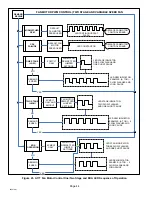

Page 39: ...Page 39 XC21 SERIES Figure 19 High Pressure Switch Operation ...

Page 40: ...Page 40 506518 01 Figure 20 Low Pressure Switch Operation ...

Page 41: ...Page 41 XC21 SERIES Figure 21 High Discharge Temperature Sensor Operation ...